Sludge/biomass treatment device and method of coal-fired power plant boiler

A technology for biomass treatment and coal-fired power plants, applied in combustion methods, solid fuel pretreatment, biofuels, etc., can solve the problems of large investment, many equipment, and high operating risks, and prevent odor generation and leakage , Prevent natural and explosive effects, improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

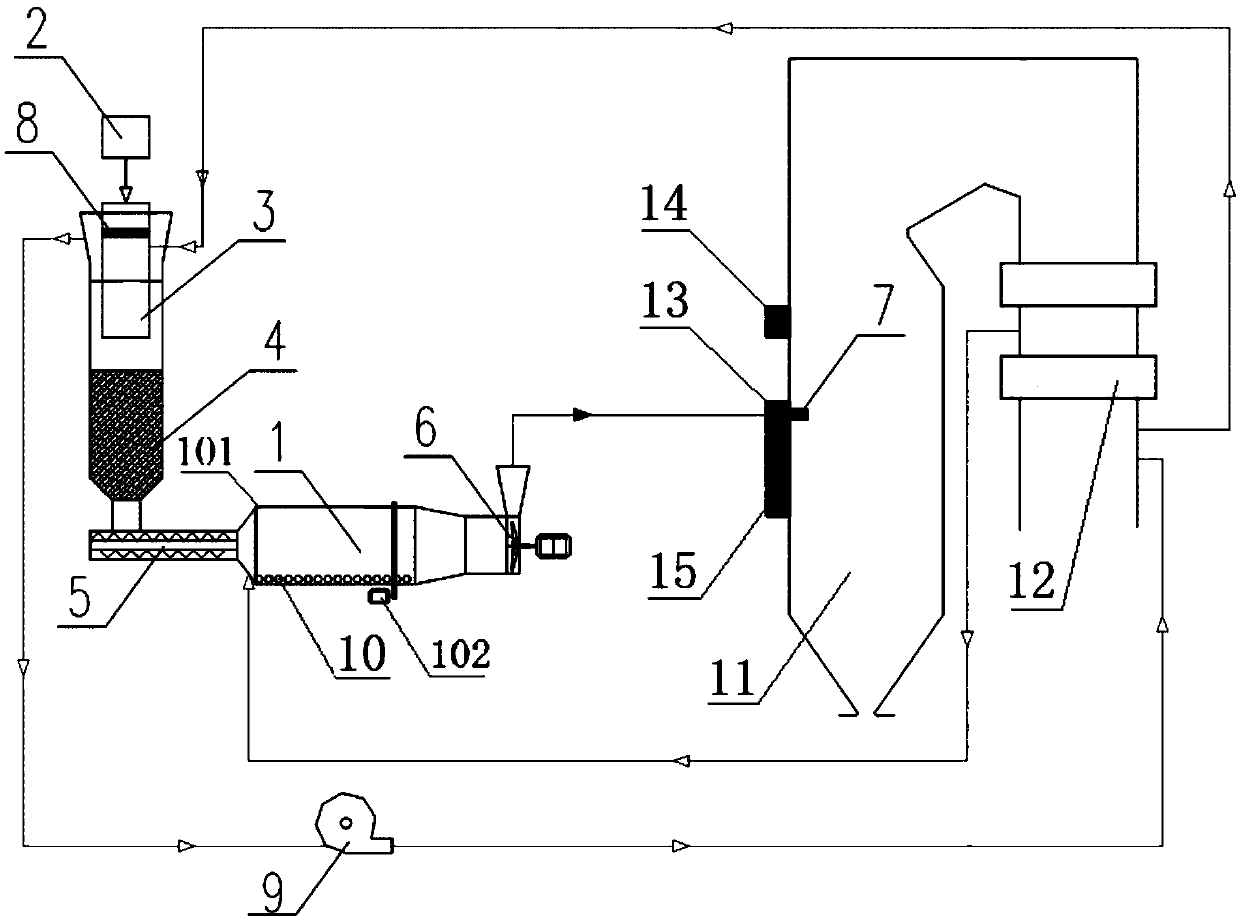

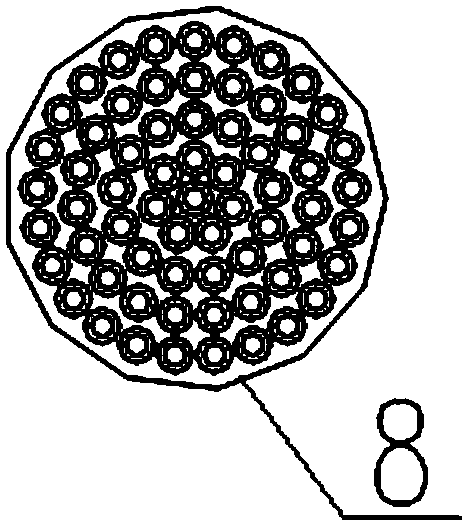

[0034] A sludge / biomass treatment device for a coal-fired power plant boiler, such as figure 1 As shown, it includes dry carbonization and conveying integrated equipment 1, feeding device 2, pre-drying device 3, storage tank 4, conveying device 5, powder discharger 6, sludge / biomass burner 7, porous disc 8, furnace Smoke fan 9, steel ball 10, boiler furnace 11, air preheater 12, OFA burner 13, SOFA burner 14 and main burner 15;

[0035]The dry carbonization conveying integrated equipment 1 includes a rotating housing 101 and a rotating drive motor 102 arranged outside the rotating housing 101; the rotating housing 101 is in the shape of a hollow cylinder, and the rotary and sealed connection of the input end adopts a screw conveyor. The conveying device 5 of the feeder, the output end is rotated and sealed to connect the powder discharge machine 6 inlets; a number of steel balls 10 are arranged in the rotating housing 101; the inlet of the rotating housing 101 is connected wit...

Embodiment 2

[0047] A method for treating sludge / biomass of a coal-fired power station boiler, comprising the following steps,

[0048] a. Close the outlet of the storage tank 4, add the wet sludge / biomass into the pre-drying device 3 through the feeding device 2, and take the low-temperature furnace smoke upstream of the outlet flue of the air preheater 12 and send it to the inlet of the pre-drying device 3 , the wet sludge / biomass is dried and evaporated by the low-temperature furnace smoke, and the pre-dried low-temperature furnace smoke carries water vapor into the downstream of the outlet flue of the air preheater 12, and the pre-dried sludge / biomass is stored in the storage Inside tank 4;

[0049] b. When the amount of sludge / biomass stored in the storage tank 4 reaches the upper limit of the storable amount, the feeding device 2 is closed, and the sludge / biomass stored in the storage tank 4 is sent to the integrated drying and carbonization conveying equipment 1, at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com