Method for compounding ferronickel hydrotalcite nano-array compound structure by utilizing in situ self-sacrificing template process and application

A nano-array, composite structure technology, applied in the fields of electrocatalysis and material science, can solve the problems of affecting the stability of electrode catalytic activity, high cost, uneven dispersion, etc., to increase catalytic active sites, solve poor conductivity, good stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a) Pretreatment of nickel-iron alloy sheets: rinse the nickel-iron alloy sheets with water and ethanol repeatedly 5-6 times to remove surface impurities, place them in absolute ethanol for ultrasonic treatment for 3 minutes, take them out and rinse them repeatedly with ultrapure water for 4 times; / L hydrochloric acid for 5 minutes of ultrasonic acidification activation, take it out and rinse it with ultrapure water for 5 times; then place it in an oven at 80°C for 60 minutes;

[0036] b) Preparation of the reaction solution: a mixed solution of 5 milliliters of water and 25 milliliters of methanol was used as a solvent, 0.6 gram of cetyltrimethylammonium bromide and 0.0168 gram of potassium hydroxide were added to the solvent, stirred at room temperature until completely dissolved, Obtain reaction solution;

[0037]c) Place the nickel-iron alloy sheet dried in step a) in a 40 ml polytetrafluoroethylene lining, and pour the reaction solution obtained in step b) into the...

Embodiment 2-5

[0041] The preparation method of embodiment 2-5 is the same as embodiment 1, only change the volume of water and methanol in the preparation of step b) reaction solution, step c) in reaction temperature and reaction time parameters, specific reaction conditions are shown in Table 1.

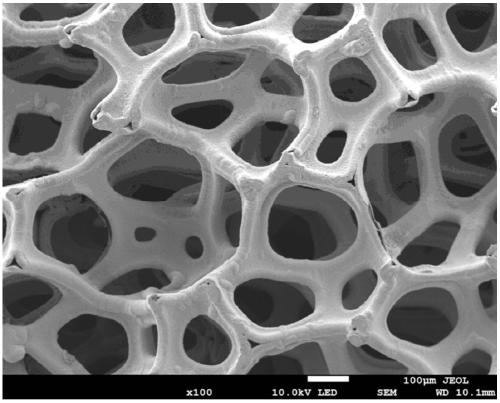

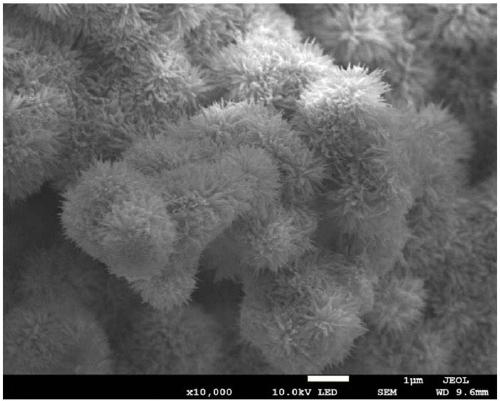

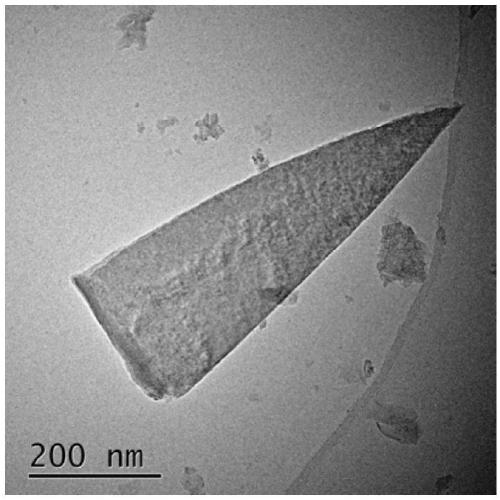

[0042] Depend on figure 1 It can be seen that the nickel-iron alloy sheet substrate has an obvious three-dimensional channel structure; figure 2 It can be seen that the nickel-iron hydrotalcite-based nano-array composite structure prepared in Example 1 is a good needle-like nano-array structure with uniform size and uniform dispersion; the smoother surface of the needle-like array structure is image 3 clearly visible in.

[0043] The nickel-iron hydrotalcite nano-array composite structure obtained in Examples 1-5 of the present invention is used as the electrochemical performance test of the oxygen evolution reaction catalyst for electrolysis of water according to the following method:

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com