Chain structure transition metal polysulfide cathode material for lithium-sulfur battery

A technology of positive electrode materials and transition metals, applied in the field of electrode materials and batteries containing them, to achieve the effects of simple process, long cycle life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A chain structure transition metal polysulfide cathode material for a lithium-sulfur battery, which is prepared by the following steps:

[0035] (1) Sulfur source and transition metal compound, the sulfur source and transition metal organic compound are evenly mixed and added to 1,2-o-dichlorobenzene organic solvent, and reacted by heating. In this embodiment, the sulfur source is sublimed sulfur; the transition metal compound is molybdenum hexacarbonyl, and the molar ratio between the sulfur source and molybdenum hexacarbonyl is 10:1 (total mass 1g). The above materials are uniformly mixed and added to 35 mL of dichlorobenzene , and stir until the mixture is a clear solution.

[0036] (2) Dissolving the sulfur source and the transition metal compound in dichlorobenzene, placing them in a container, and keeping them warm for 2 hours at a high temperature of 185°C;

[0037] (3) centrifuging and drying the mixed solution obtained in (2) to obtain transition metal polysul...

Embodiment 2

[0039] A chain structure transition metal polysulfide cathode material for a lithium-sulfur battery, which is prepared by the following steps:

[0040] (1) Sulfur source and transition metal compound, the sulfur source and transition metal organic compound are uniformly mixed, then added to methanol organic solvent, and reacted by heating. In this embodiment, the sulfur source is thioacetamide; the transition metal compound is ammonium metavanadate, and the mass ratio between the sulfur source and ammonium metavanadate is 5:1 (the total mass is 1 g).

[0041] (2) Dissolve the sulfur source and the transition metal compound in 35mL of methanol, stir for 30min, place in a container, and keep warm at a high temperature of 160°C for 12h;

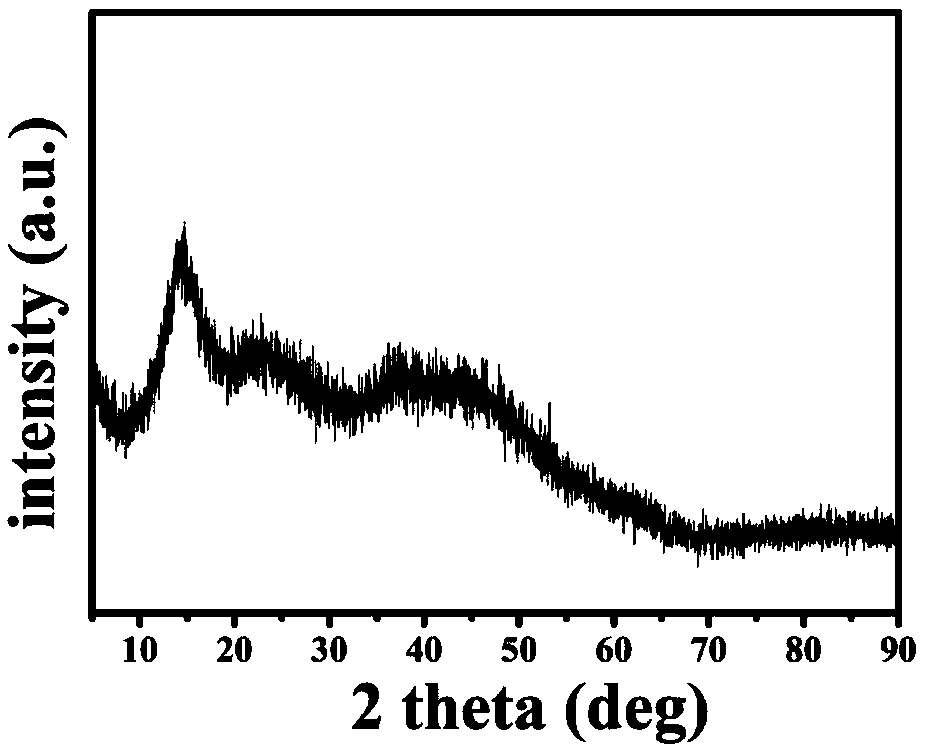

[0042] (3) centrifuging and drying the mixed solution obtained in (2) to obtain transition metal polysulfides as positive electrode materials. The resulting product is a powder, and the results of X-ray diffraction are shown in Image 6 , prov...

Embodiment 3

[0044] A chain structure transition metal polysulfide cathode material for a lithium-sulfur battery, which is prepared by the following steps:

[0045] (1) Sulfur source and transition metal compound, the sulfur source and transition metal organic compound are evenly mixed and added to 1,2-o-dichlorobenzene organic solvent, and reacted by heating. In this embodiment, the sulfur source is sublimed sulfur; the transition metal compound is molybdenum hexacarbonyl, and the molar ratio between the sulfur source and molybdenum hexacarbonyl is 10:1 (total mass 1g). The above materials are uniformly mixed and added to 35 mL of dichlorobenzene , and stir until the mixture is a clear solution.

[0046] (2) Dissolve the sulfur source and the transition metal compound in dichlorobenzene, place them in a container, and keep them warm for 12 hours at a high temperature of 185°C;

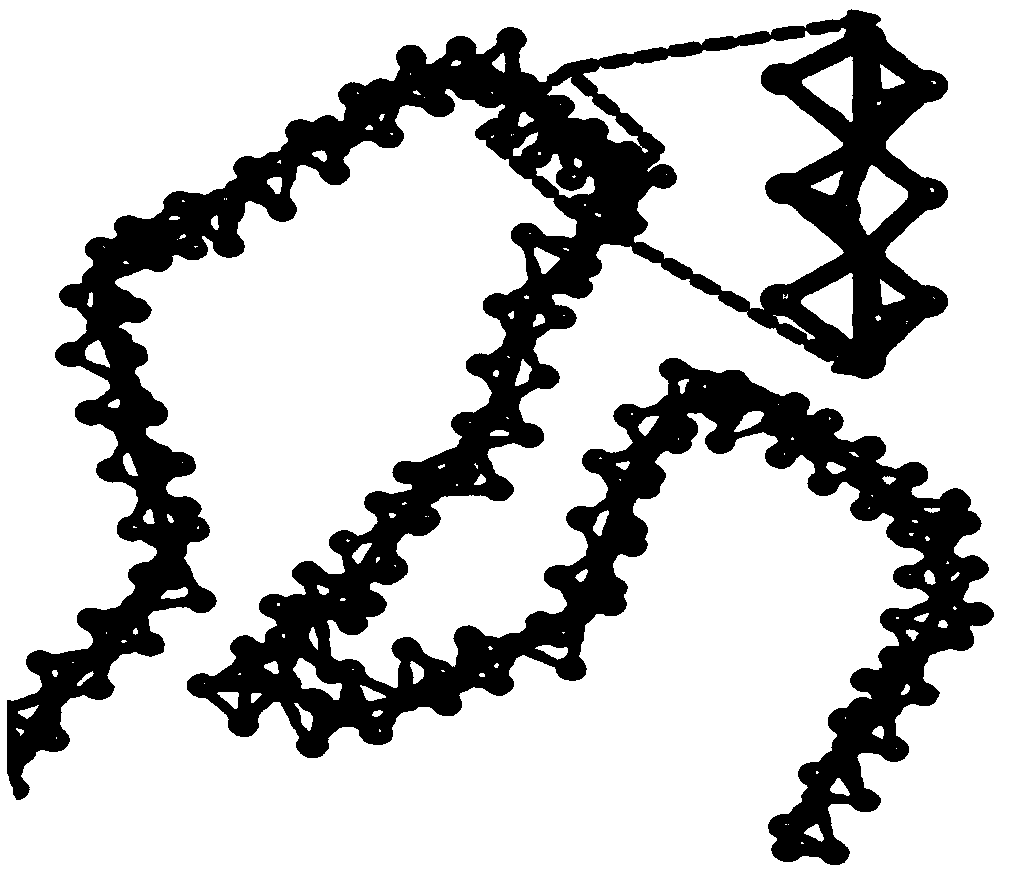

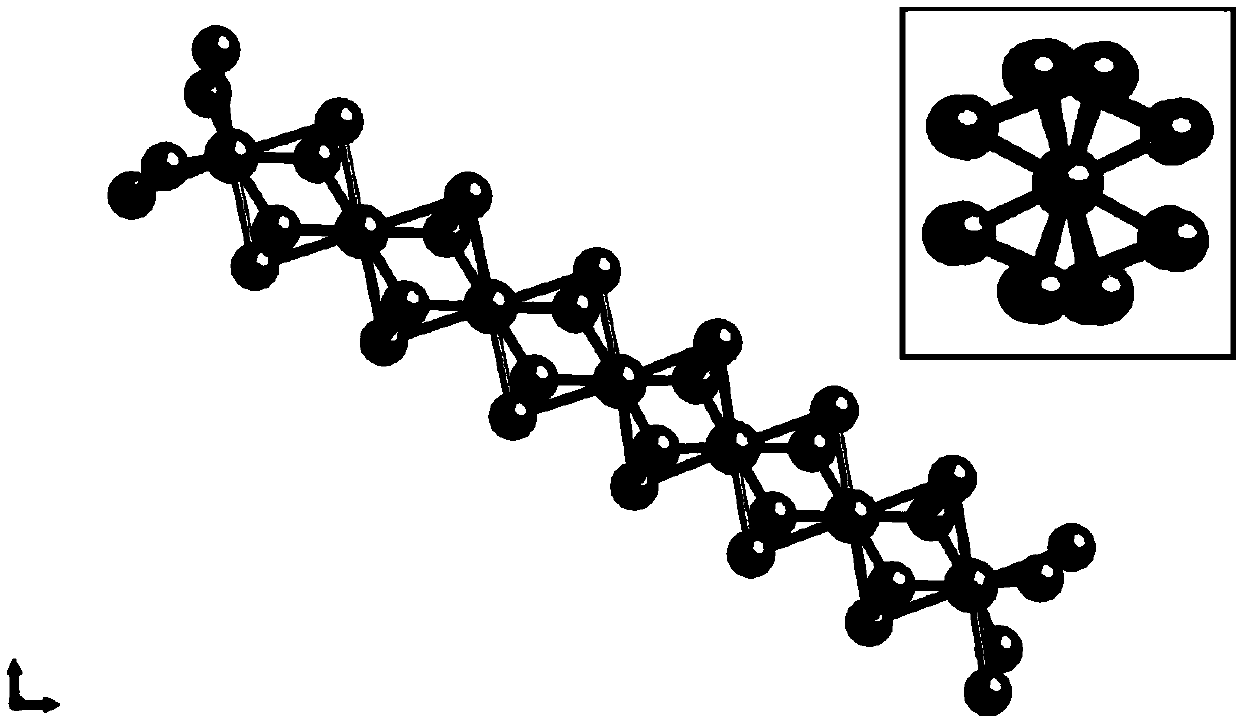

[0047](3) centrifuging and drying the mixed solution obtained in (2) to obtain transition metal polysulfides a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com