Integrated sewage treatment recycling equipment with pretreatment tank

A pretreatment tank and sewage treatment technology, applied in the field of livestock and poultry breeding wastewater treatment, can solve the problems of poor treatment effect, great influence of treatment process, heavy design workload, etc., achieve good environmental benefits, save secondary investment, The effect of high operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

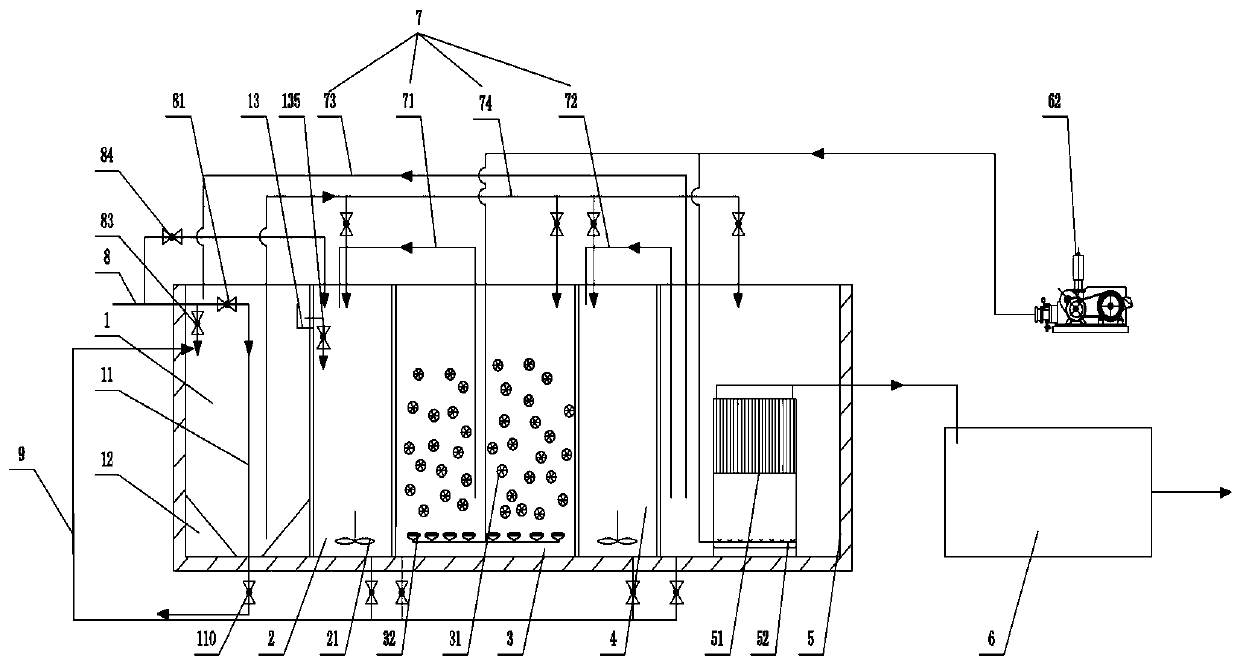

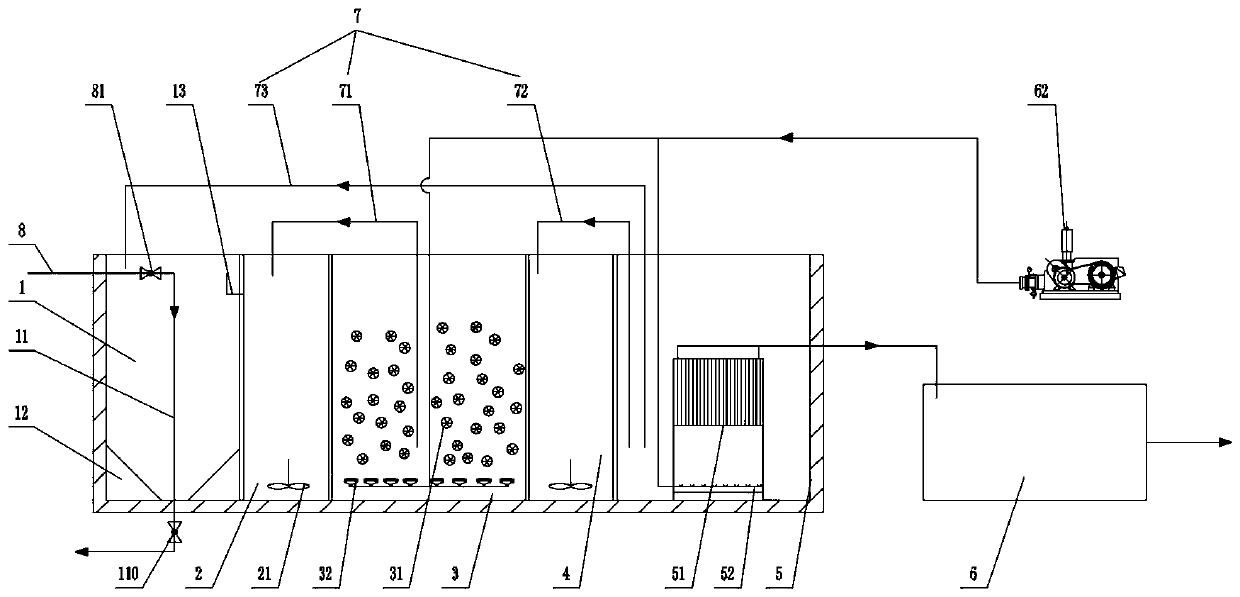

[0064] The integrated sewage treatment and reuse equipment with the pretreatment tank 1 of the present embodiment, refer to image 3 , the pretreatment tank 1 is a hydrolytic acidification tank, wherein the reflux of the third reflux device 73 is mainly sludge, when the concentration of organic matter in the influent biogas slurry is very high, the concentration of organic matter in the influent water can be further reduced by the hydrolysis acidification tank, thereby Reduce the impact on subsequent processing units. Wherein the third valve 83 (the water inlet valve on the upper part of the pretreatment tank 1) and the fourth valve 84 (the water inlet valve of the first stage anoxic tank 2) are normally closed. When the integrated equipment enters water, open the first valve 81 (the water inlet distribution pipe valve at the bottom of the pretreatment pool 1), close the second valve 110 (the sludge discharge valve of the pretreatment pool 1), and the waste water passes throug...

Embodiment 2

[0066] The integrated sewage treatment and reuse equipment with the pretreatment tank 1 of the present embodiment, refer to image 3 , the pretreatment pool 1 is an anoxic pool, wherein the reflux of the third reflux device 73 is mainly nitrification liquid. The denitrifying bacteria in the tank use the organic carbon source in the influent and the nitrification liquid returned from the MBR membrane tank to perform denitrification and denitrification reaction, thereby improving the overall denitrification capacity of the integrated equipment. The water intake of the integrated equipment only enters from the bottom of the pretreatment tank 1, that is, the third valve 83 (the upper water inlet valve of the pretreatment tank 1) and the fourth valve 84 (the water inlet valve of the first-stage anoxic tank 2) are normally closed state. When the integrated equipment enters water, open the first valve 81 (the water inlet distribution pipe valve at the bottom of the pretreatment pool...

Embodiment 3

[0068] The integrated sewage treatment and reuse equipment with the pretreatment tank 1 of the present embodiment, refer to Figure 4 , the pretreatment pond 1 is a sedimentation pond, and when the influent biogas slurry contains a large amount of biogas residue, the sedimentation pond can effectively settle and discharge the biogas residue in the influent water, thereby reducing the impact on subsequent treatment units. The water intake of the integrated equipment only enters from the upper part of the pretreatment tank 1, that is, the first valve 81 (the water inlet valve of the pretreatment tank 1) and the fourth valve 84 (the water inlet valve of the first anoxic tank 2) are normal closed, the perforated pipe 11 at the bottom of the pretreatment tank 1 is only used as a mud discharge pipe. When the equipment is fed with water, open the third valve 83 (water inlet valve on the upper part of the pretreatment pond 1), and the biogas slurry enters the pond from the water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com