Formaldehyde-free fiber board, preparation method thereof, and environment-friendly processing technology for furniture

A processing technology and fiberboard technology, applied in the directions of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of delamination, low environmental protection coefficient, poor surface flatness, etc. The effect of increasing the surface area, improving the environmental protection factor, and improving the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

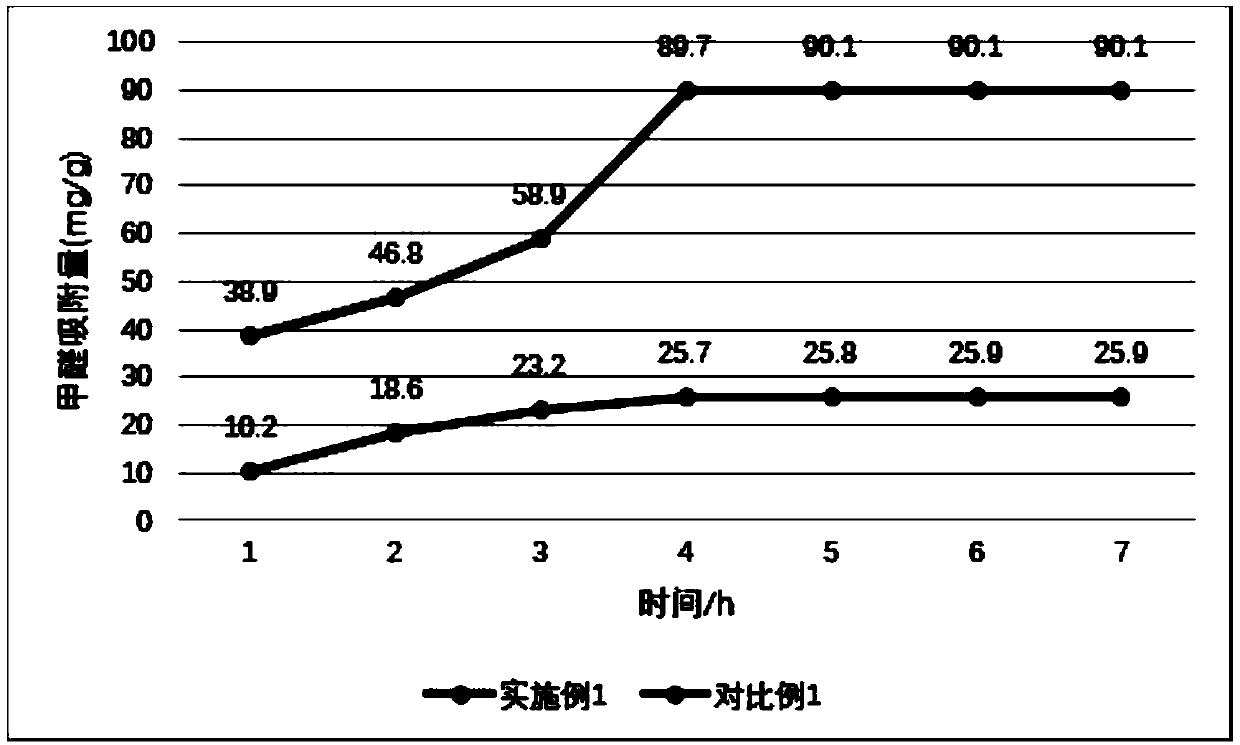

[0050] Example 1: A formaldehyde-free fiberboard, prepared from the following components by weight: 70 parts of modified bamboo charcoal, 10 parts of spider plant extract, 5 parts of negative ion powder, 3 parts of nano photocatalyst, 1.5 parts of water-based polyurethane adhesive 5 parts of ivy extract, 5 parts of aloe extract, 100 parts of distilled water, 40 parts of bamboo fiber;

[0051] Wherein the modified bamboo charcoal is prepared by the following method: (1) putting the bamboo charcoal into distilled water, stirring for 20 minutes after boiling until boiling, cooling and filtering, and washing with distilled water until the filtrate is clear;

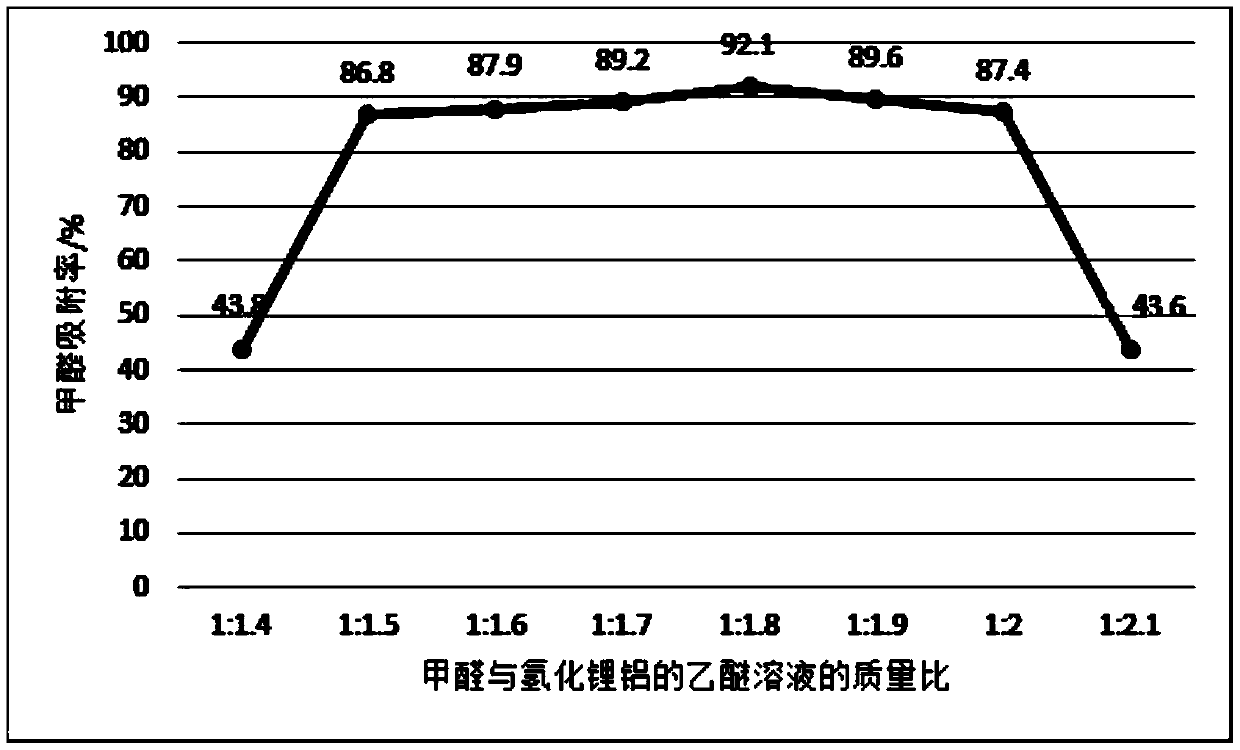

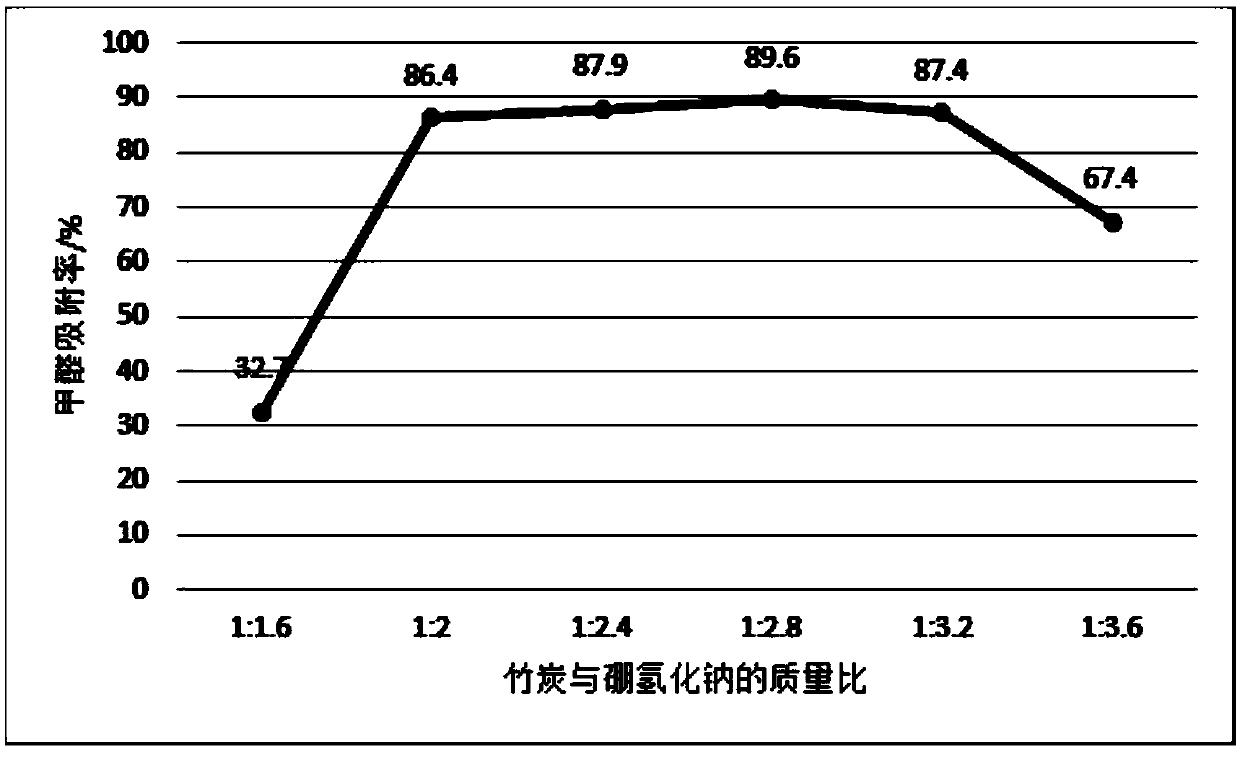

[0052] (2) Dry the bamboo charcoal at 105°C for 10 hours, then put the bamboo charcoal into a sodium borohydride solution with a concentration of 20g / mL, the mass ratio of bamboo charcoal to sodium borohydride is 1:2.8, shake at 25°C 3 hours, suction filtration;

[0053] (3) Then add an ether solution of lithium aluminum hyd...

Embodiment 2-6

[0068] Example 2-6: a formaldehyde-free fiberboard, the difference from Example 1 is that the components contained and the parts by weight corresponding to each component are shown in Table 1.

[0069] Components contained in the formaldehyde-free fiberboard and the corresponding parts by weight of each component in Table 1 Example 2-6

[0070]

[0071]

Embodiment 7-10

[0072] Embodiment 7-10: a kind of formaldehyde-free fiberboard, the difference from embodiment 1 is that the components contained in the negative ion powder and the most important parts by weight of each component are shown in Table 2.

[0073] The components that negative ion powder comprises in the embodiment 7-10 of table 2 and the corresponding parts by weight of each component

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com