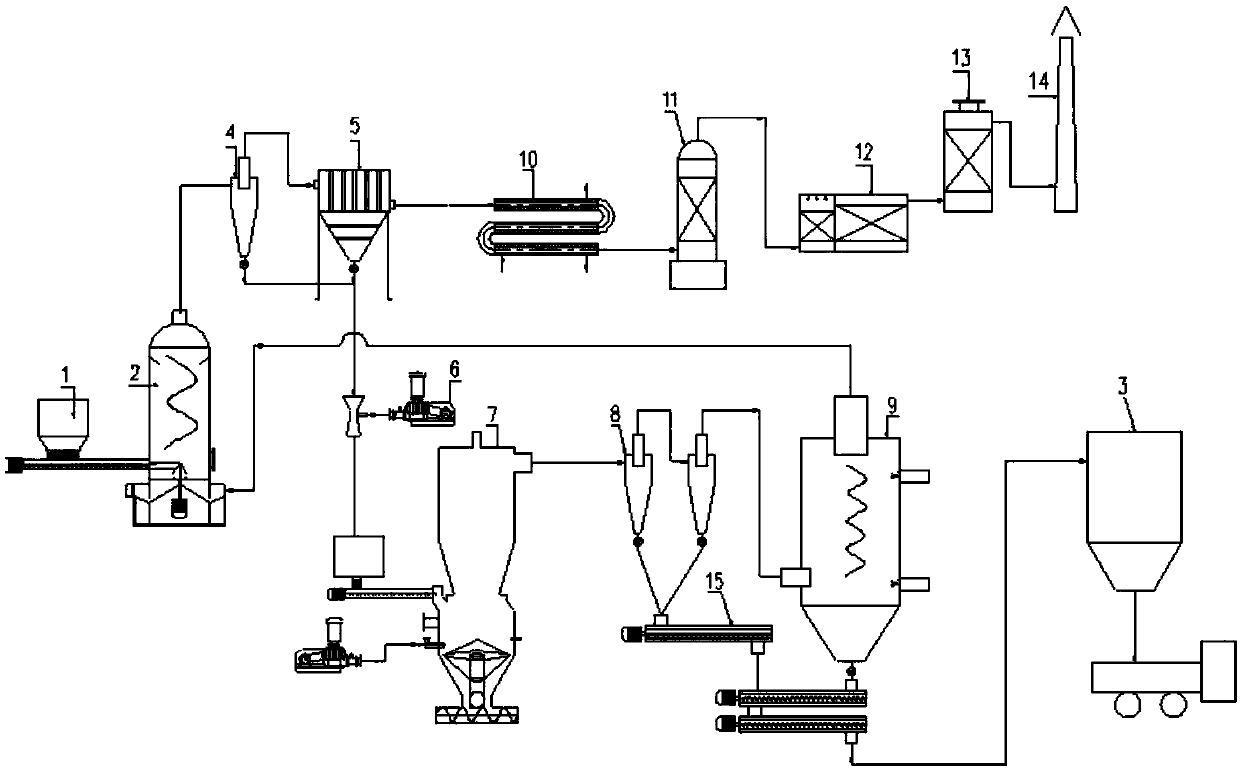

Urban organic solid waste coupling dry pyrolysis gasification system

A technology of organic solid waste, pyrolysis and gasification, which is used in pyrolysis treatment of sludge, gas dust removal, combined devices, etc. Chain length and other problems, to achieve the effect of strong process controllability and operability, reducing exhaust gas treatment costs and reducing heat conversion links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

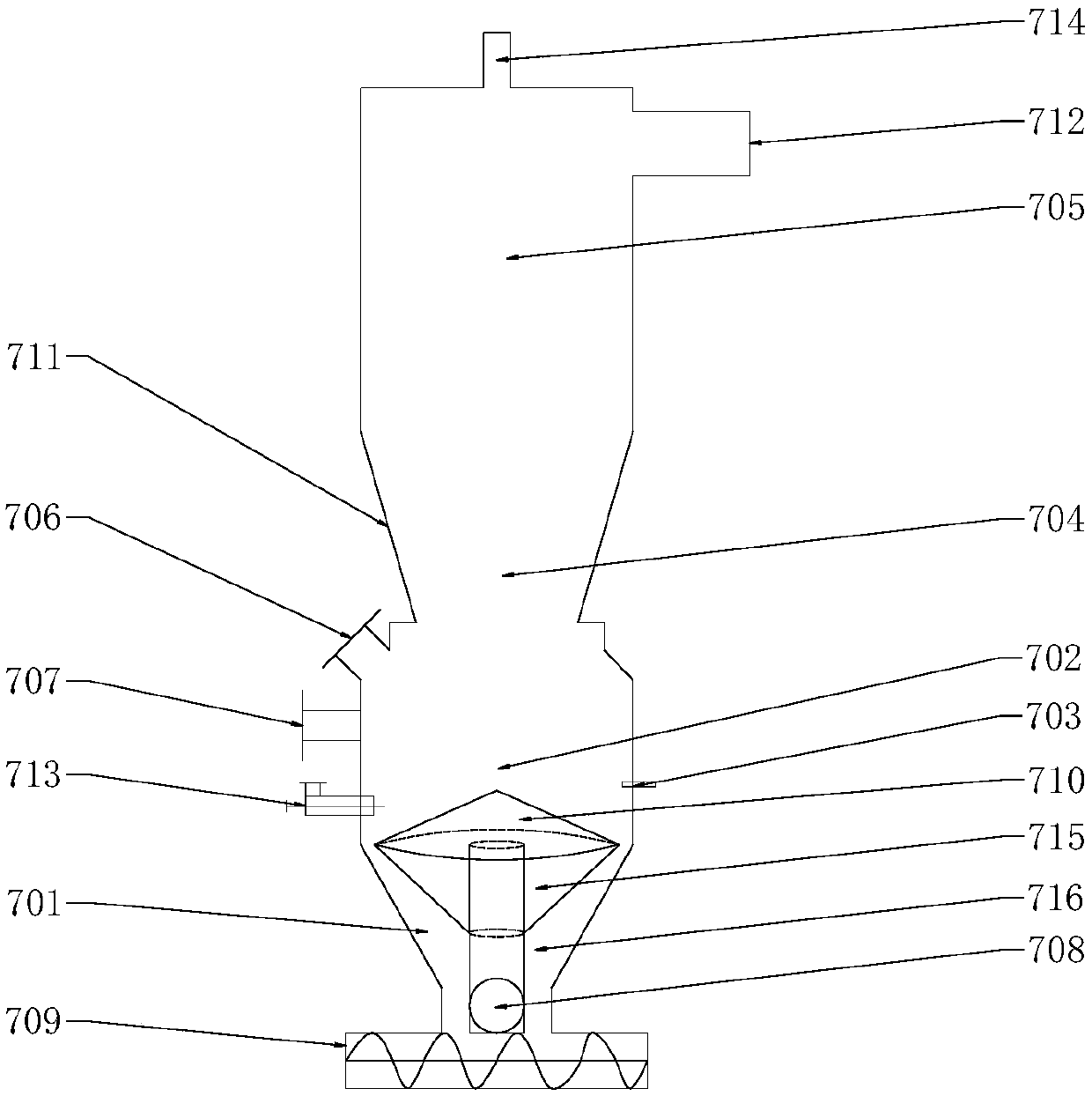

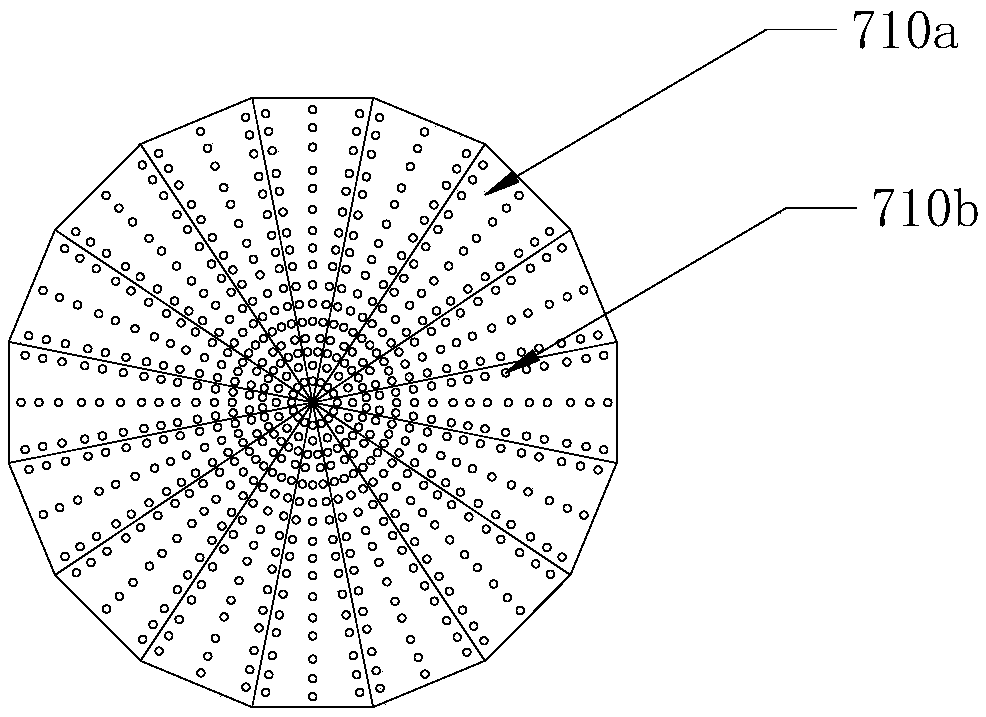

Method used

Image

Examples

specific example

[0047] The dewatered sludge (water content 80%) of a sewage plant is 120 tons / day, and the dry sludge conveying screw pump is used to send it to the sludge feeding storage device, and then enters the pre-drying device for drying, reducing the water content to 20-30 %, the reduction is 30-34.3 tons. After drying, the sludge is sent to the cyclone fluidized bed gasification furnace through the Roots blower pneumatic conveying equipment. The pyrolysis reaction temperature is 600-800°C. After the pyrolysis reaction, 11.0-13.0 tons of ash and pyrolysis gas are produced. After being cooled to 100°C by the cold slag conveyor, it is densely transported into the ash slag bin by the warehouse pump, and then transported to the brick factory to manufacture pavement bricks and other products for final disposal and resource utilization. The combustible gas is separated from the ash by the high-temperature separator The slag is sent to the second combustion chamber to generate high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com