Water-based environmental protection paint and production technology thereof

An environmentally friendly coating and production process technology, applied in antifouling/underwater coatings, fireproof coatings, coatings, etc., can solve problems such as damage to the liver, kidneys, brain and nervous system, headache, nausea, vomiting, fatigue, memory loss, etc. , to achieve the effect of shortening the grinding time, good steric hindrance effect and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

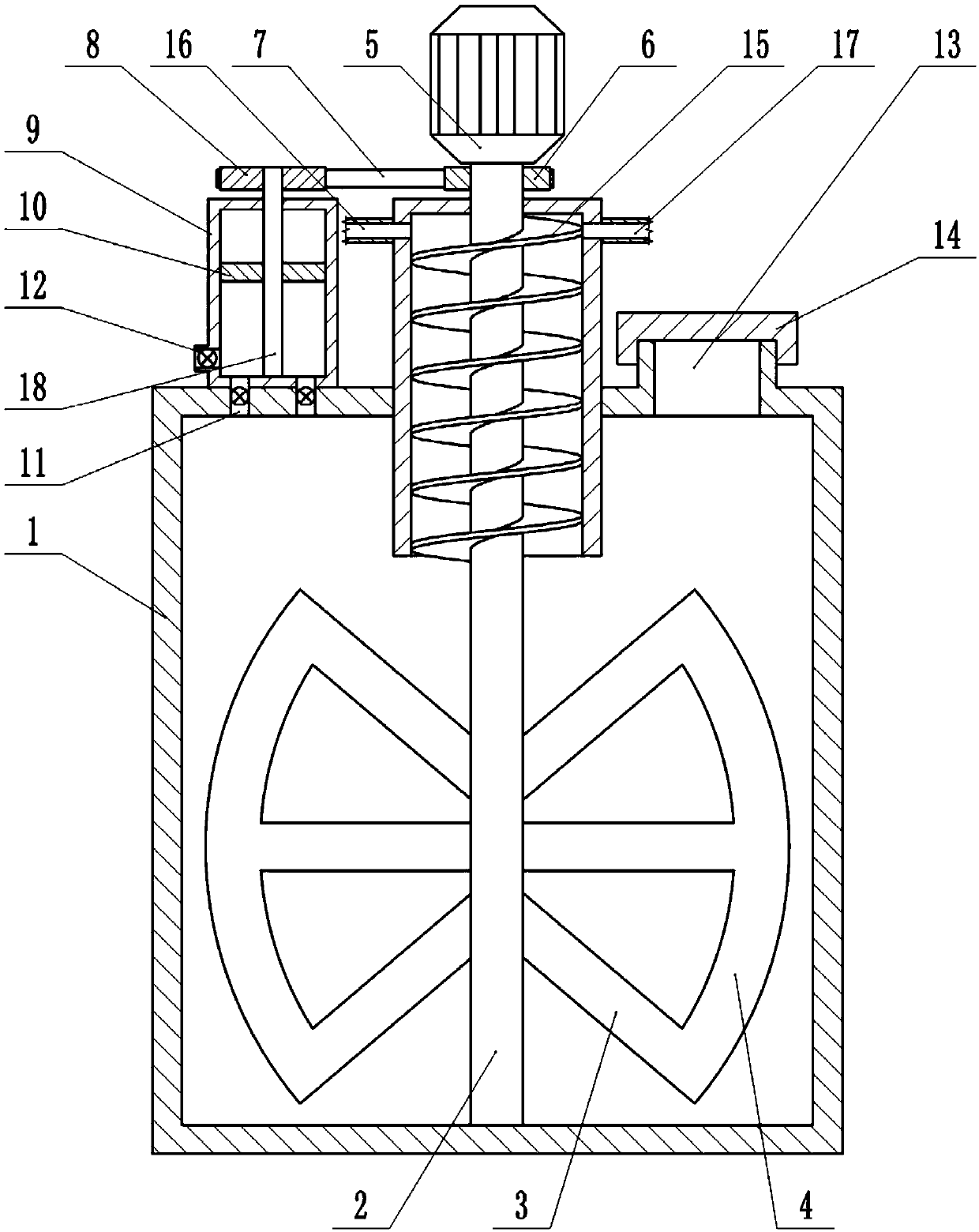

Method used

Image

Examples

Embodiment 1

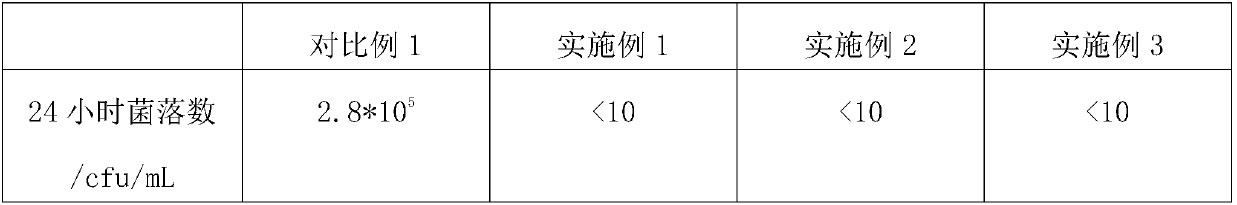

[0023] A water-based environmental protection coating, the components include 30kg of water, 17kg of acrylic emulsion, 0.4kg of penetrating wetting agent, 0.2kg of defoamer, 1kg of dispersant, 17kg of titanium dioxide, 12kg of talcum powder, 0.4kg of flame retardant, antiseptic and antibacterial agent 0.3kg, the flame retardant is magnesium hydroxide and water glass, which is prepared by mixing with a weight ratio of 2:3, and the antiseptic and antibacterial agent is isothiazolinone and deacetylated chitin, which is prepared by mixing with a weight ratio of 7:3 become.

[0024] A kind of production technology of water-based environmental protection paint, comprises the following steps:

[0025] Step 1: Prepare 30kg of water, 17kg of acrylic emulsion, 0.4kg of penetrating wetting agent, 0.2kg of defoamer, 1kg of dispersant, 17kg of titanium dioxide, 12kg of talcum powder, 0.4kg of flame retardant, 0.3kg of anti-corrosion and antibacterial agent, flame retardant The agent is ma...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is:

[0038] A water-based environmental protection coating, the components include 25kg of water, 15kg of acrylic emulsion, 0.3kg of penetrating wetting agent, 0.1kg of defoamer, 1kg of dispersant, 15kg of titanium dioxide, 9kg of talcum powder, 0.3kg of flame retardant, antiseptic and antibacterial agent 0.2kg, the flame retardant is magnesium hydroxide and water glass, prepared by mixing at a weight ratio of 2:3, and the antiseptic and antibacterial agent is isothiazolinone and chitin, mixed and prepared at a weight ratio of 7:3 become.

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is:

[0041] A water-based environmental protection coating, the components include 35kg of water, 20kg of acrylic emulsion, 0.5kg of penetrating wetting agent, 0.3kg of defoamer, 1kg of dispersant, 20kg of titanium dioxide, 14kg of talcum powder, 0.5kg of flame retardant, anti-corrosion and antibacterial agent 0.4kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com