Tear-resistant aromatic cigarette paper

A cigarette paper and tear-resistant technology, which is applied in the field of papermaking, can solve the problems of poor taste and easy torn taste of cigarette paper, and achieve the effects of improving efficiency, avoiding unintentional tearing, and high water holding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

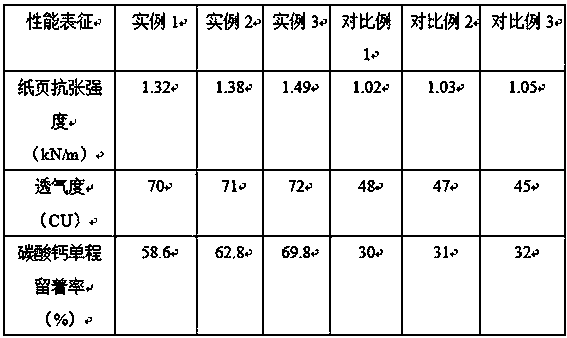

Examples

preparation example Construction

[0033] The preparation method of cigarette paper base material comprises the following steps:

[0034] (1) According to the mass ratio of 5:1~3, take grape stems and grape seeds, mix them with boiling water, rinse them for 2~4 times, dry them naturally, move them to a pulverizer and crush them through a 120-mesh sieve, and take the sieved particles at 35~50°C According to the mass ratio of 5:14~25:1, add sodium bicarbonate solution with a mass fraction of 20% and fructose, mix and stir, then move to a beater and beat at a speed of 5000~6800r / min for 6~10min to obtain a slurry, take the pulp The material is homogenized in a colloid mill at a speed of 3000~4500r / min for 8~15min to obtain a homogenate. After the homogenate is mixed with additives at a mass ratio of 15~25:1, it is transferred to a rotary evaporator at a temperature of 55~65 Under the conditions of ℃ and pressure of 500~600kPa, rotary evaporation and concentration for 3~5h, to obtain the concentrate;

[0035] (2) At...

example 1

[0042] Auxiliary: Mix polyvinyl alcohol and hydroxyalkyl starch at a mass ratio of 1:1 to obtain an auxiliary.

[0043] Activation medium: in parts by mass, mix 30 parts of potatoes, 20 parts of glucose, 3 parts of yeast extract, 1 part of disodium hydrogen phosphate, and 800 parts of water, and sterilize at 121°C for 15 minutes to obtain the activation medium.

[0044] Fermentation medium: in parts by mass, take 20 parts of watermelon juice, 3 parts of peptone, 1 part of disodium hydrogen phosphate, 1 part of potassium dihydrogen phosphate, 3 parts of guar gum, 0.8 part of citric acid, 4 parts of yeast extract, Mix 800 parts of water and sterilize at 121°C for 15 minutes to obtain the fermentation medium.

[0045] Additive: Mix propylene glycol and 10% acetic acid solution at a mass ratio of 1:4 to obtain the additive.

[0046] Pretreatment of brewer's grains: take brewer's grains and wash them with water, move them to a 65°C oven for 3 hours, and then crush them through a 1...

example 2

[0058] Auxiliary: Mix polyvinyl alcohol and hydroxyalkyl starch at a mass ratio of 1:2 to obtain an auxiliary.

[0059] Activation medium: in parts by mass, take 40 parts of potatoes, 25 parts of glucose, 5 parts of yeast extract, 3 parts of disodium hydrogen phosphate, and 900 parts of water, mix them, and sterilize at 121°C for 17 minutes to obtain the activation medium.

[0060] Fermentation medium: in parts by mass, take 30 parts of watermelon juice, 4 parts of peptone, 3 parts of disodium hydrogen phosphate, 3 parts of potassium dihydrogen phosphate, 5 parts of guar gum, 1.4 parts of citric acid, 6 parts of yeast extract, Mix 900 parts of water and sterilize at 121°C for 18 minutes to obtain the fermentation medium.

[0061] Additive: Mix propylene glycol and 10% acetic acid solution at a mass ratio of 1:6 to obtain the additive.

[0062] Pretreatment of brewer's grains: Take brewer's grains and wash them with water, move them to a 72°C oven for 5 hours, and then crush t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com