Pearl wool for low-frequency electromagnetic physical therapy cushion and preparation method thereof

A technology of electromagnetic physiotherapy and pearl cotton, which is applied in the field of pearl cotton of low-frequency electromagnetic physiotherapy pads and its preparation, can solve the problem of flame retardancy, antibacterial performance to be improved, no antibacterial effect, flame retardancy, antistatic and antibacterial properties, etc. problems, to achieve good antistatic and flame retardant performance, excellent antibacterial effect, long-term antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

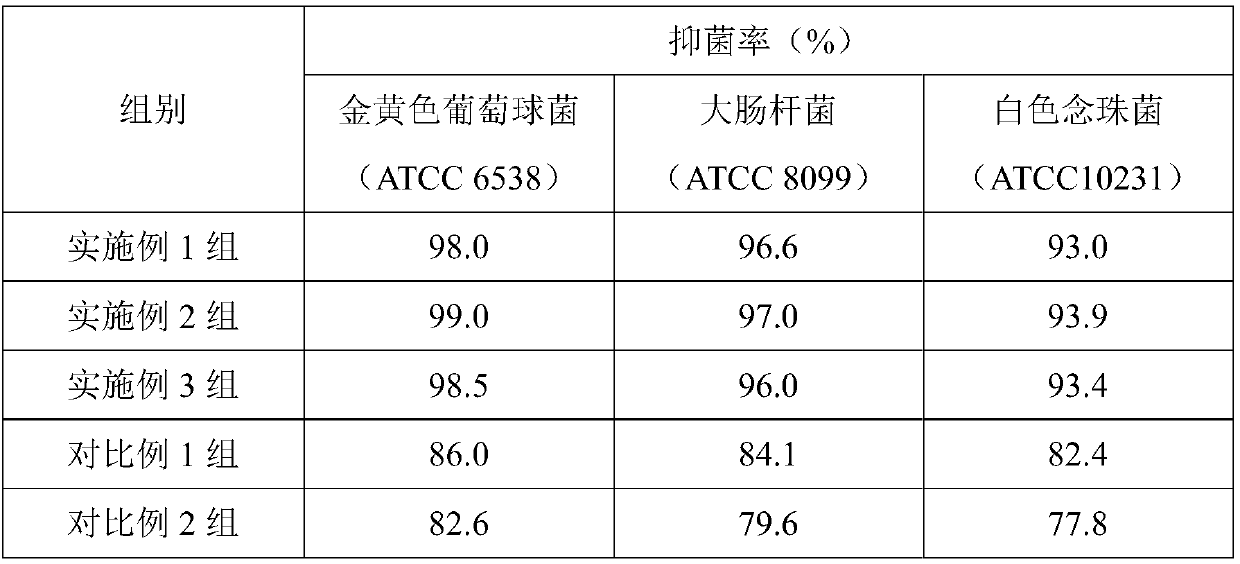

Examples

Embodiment 1

[0021] Embodiment 1 A kind of pearl cotton for low-frequency electromagnetic physiotherapy pad

[0022] The pearl cotton used for the low-frequency electromagnetic physiotherapy pad consists of the following components and parts by weight thereof:

[0023] 80 parts of low-density polyethylene resin, 0.5 parts of attapulgite, 0.5 parts of silane coupling agent, 0.5 parts of kaolin, 1.0 parts of talcum powder, 0.2 parts of butane, 0.2 parts of monoglyceride, 0.03 parts of masterbatch, ethoxylated alkane 3 parts of base amine, 0.1 part of antibacterial agent and 5 parts of flame retardant.

[0024] Described antibacterial agent is chitosan / allyl triphenyl phosphorus chloride graft copolymer, preparation method is: join 0.3g chitosan in the acetic acid solution that 60mL concentration is 2%, heat to 45 ℃, Stir until dissolved, then sequentially add 0.1M initiator cerium nitrate solution 4mL and 0.6g monomer allyltriphenylphosphine chloride, react under nitrogen for 5h, cool, adju...

Embodiment 2

[0029] Embodiment 2 A kind of pearl cotton for low-frequency electromagnetic physiotherapy pad

[0030] The pearl cotton used for the low-frequency electromagnetic physiotherapy pad consists of the following components and parts by weight thereof:

[0031] Low-density polyethylene resin 100 parts, attapulgite 0.75 parts, silane coupling agent 0.75 parts, kaolin 1.0 parts, talcum powder 1.25 parts, butane 0.4 parts, monoglyceride 0.5 parts, masterbatch 0.05 parts, ethoxylated alkanes 5 parts of base amine, 0.3 parts of antibacterial agent and 7.5 parts of flame retardant.

[0032] Described antibacterial agent is chitosan / allyl triphenyl phosphorus chloride graft copolymer, preparation method is: join 0.3g chitosan in the acetic acid solution that 60mL concentration is 2%, heat to 45 ℃, Stir until dissolved, then sequentially add 0.1M initiator cerium nitrate solution 4mL and 0.6g monomer allyltriphenylphosphine chloride, react under nitrogen for 5h, cool, adjust pH to 12, fil...

Embodiment 3

[0035] Embodiment 3 A kind of pearl cotton for low-frequency electromagnetic physiotherapy pad

[0036] The pearl cotton used for the low-frequency electromagnetic physiotherapy pad consists of the following components and parts by weight thereof:

[0037]120 parts of low-density polyethylene resin, 1.0 parts of attapulgite, 1.0 parts of silane coupling agent, 1.5 parts of kaolin, 1.5 parts of talc, 0.6 parts of butane, 0.8 parts of monoglyceride, 0.07 parts of masterbatch, ethoxylated alkanes 7 parts of base amine, 0.5 parts of antibacterial agent and 10 parts of flame retardant.

[0038] Described antibacterial agent is chitosan / allyl triphenyl phosphorus chloride graft copolymer, preparation method is: join 0.3g chitosan in the acetic acid solution that 60mL concentration is 2%, heat to 45 ℃, Stir until dissolved, then sequentially add 0.1M initiator cerium nitrate solution 4mL and 0.6g monomer allyltriphenylphosphine chloride, react under nitrogen for 5h, cool, adjust pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com