A kind of acetic acid and xylose co-utilization Kluyveromyces marx strain and screening method

A technology of xylose and yeast, which is applied in the field of Kluyveromyces marx strains and screening, can solve the problems of shortage and limitation of the application of cellulosic ethanol, and achieve the effects of good growth, lower production cost and higher yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

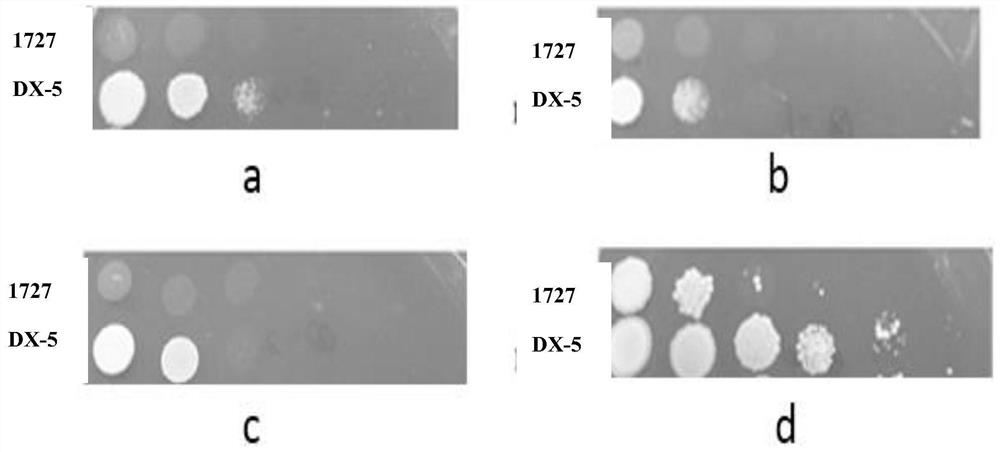

[0037] Example 1: Screening of hydrolyzate-resistant yeast Kluyveromycesmarxianus DX-5

[0038] Straw steam explosion pretreatment liquid is obtained by using pulverized straw, material-water ratio 1:10, 1% sulfuric acid, 130°C, 2h. The hydrolyzate contains 30g / L xylose, 3g / L acetic acid and 0.9g / L formic acid. Add 2% glucose, 0.2% yeast extract, and 1% peptone to 10% extract hydrolyzate to make a medium for initial directed evolution. Inoculate the starting strain of Kluyveromycesmarxianus, the optical density value at 620nm (OD620) ≈ 0.3; culture at 40°C, 150rmp / min for 48 hours, when the OD620≥2.0, collect the cells; add 2% glucose to the 15% extraction hydrolyzate according to OD620 ≈ 0.3 , yeast extract 0.2%, and peptone 1% to continue directional domestication. Repeat this step to increase the hydrolyzate content in the acclimatization medium to 100%. But when OD620≥2.0, collect the cells, smear on the 100% hydrolyzate medium plate containing 1.5% agar, pick a single ...

Embodiment 2

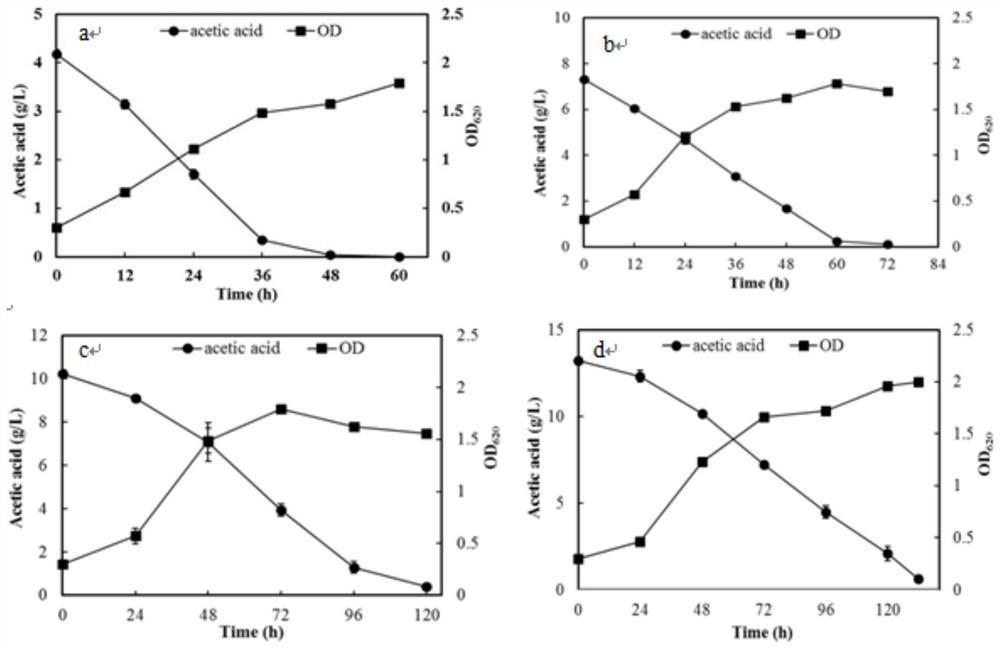

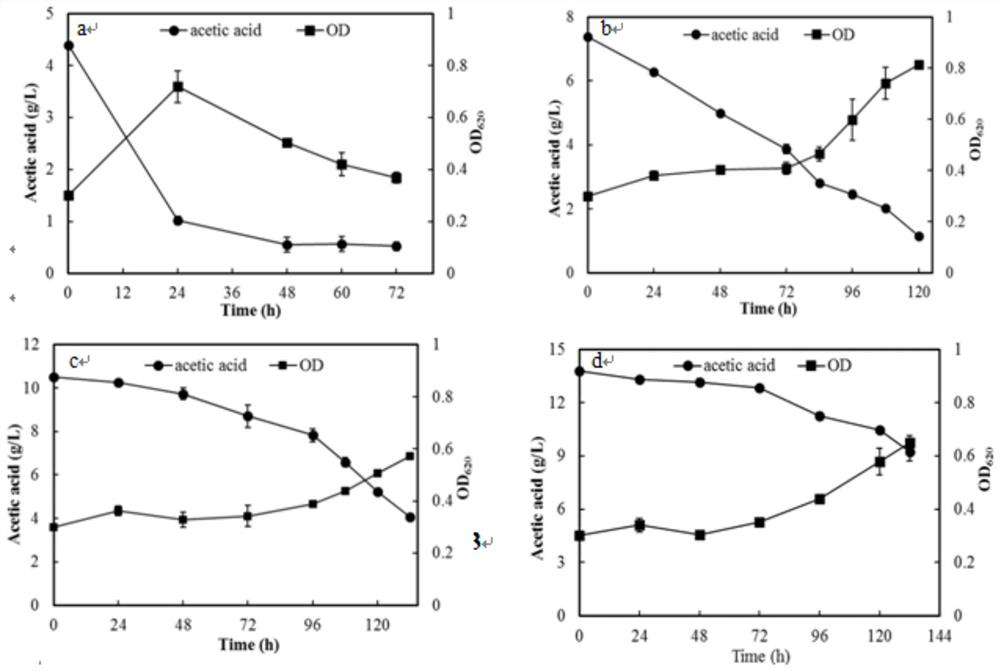

[0039] Embodiment 2: The growth status of Kluyveromycesmarxianus DX-5 in different concentrations of acetic acid

[0040] Kluyveromycesmarxianus DX-5 was cultured in YPD medium at 40°C for 24 hours, and then inoculated into different concentrations and different types of medium according to OD620≈0.3. Kluyveromyces marxianus DX-5 can grow with different concentrations of acetic acid as the sole carbon source, and the addition of organic nitrogen sources will promote the utilization of acetic acid compared with inorganic nitrogen sources. With the increase of acetic acid concentration, the growth rate of yeast cells decreased and the depletion time of acetic acid prolonged. In the organic nitrogen source, 13g / L acetic acid can be completely consumed in 130h, and the OD620 reaches about 2. See attached for specific results figure 2 , image 3 .

Embodiment 3

[0041] Example 3: KluyveromycesmarxianusDX-5 co-utilization of xylose and acetic acid status

[0042] Kluyveromycesmarxianus DX-5 was cultured in YPD medium at 40°C for 24 hours, and then inoculated into medium containing 10g / L acetic acid and 20g / L xylose according to OD620≈0.3.

[0043] Kluyveromycesmarxianus DX-5 can utilize both acetic acid and xylose. Compared with xylose growth without acetic acid, addition of high concentration of acetic acid decreased the rate of xylose utilization but increased xylitol production. See attached for specific results Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com