Method for extracting battery-grade lithium carbonate from magnesium sulfate subtype salt lake brine

A magnesium sulfate subtype and salt lake brine technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of inability to produce battery-grade lithium carbonate products, imperfect process combination, and large loss of lithium ions. To achieve the effect of controllable product quality, low production cost and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

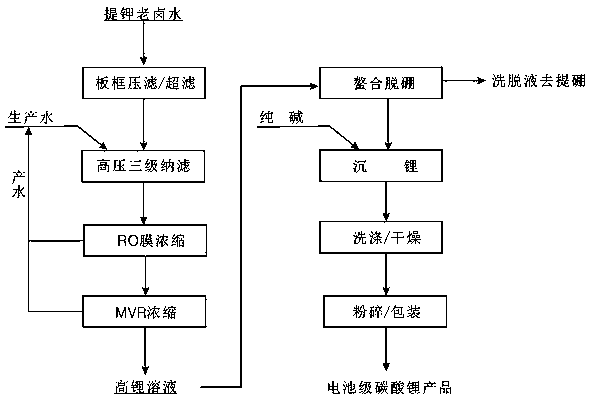

Method used

Image

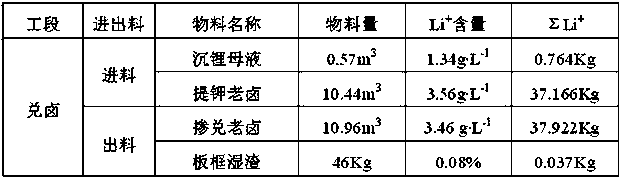

Examples

Embodiment 1

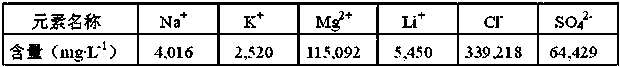

[0053] The raw material is taken from the old brine after potassium extraction from the Dachaidan Salt Lake in Qaidam Basin, Qinghai. It has the chemical composition shown in Table 1. From the composition analysis, the water chemical type of the brine system belongs to the magnesium sulfate subtype.

[0054] Table 1 Chemical composition of the brine from the Dachaidan Salt Lake in Qinghai Qaidam Basin

[0055]

[0056] ⑴ Extract 1.00m 3 Table 1 Extract potassium and old brine, add fly ash at 1% of the weight of the old brine, turn on the stirring, 10 minutes later, use the slurry pump to drive into the plate and frame filter press to filter, and obtain the filter residue 40Kg, and the refined filtrate is 0.96 m. 3 , Control filtrate NTU <20, SDI <200.

[0057] ⑵Dilute with production water once to refine the old brine 10 times to 9.6m 3 , Use a centrifugal pump to filter into the ultrafiltration device, close the concentrated water valve, and control the filtrate NTU 3 , Put into PP s...

Embodiment 2

[0064] The raw materials are taken from the old brine after potassium extraction from the Jinel Salt Lake in Dongtai, Qaidam Basin, Qinghai. It has the chemical composition shown in Table 2. From the composition analysis, the water chemical type of the brine system belongs to the magnesium sulfate subtype. This example and the examples 1 Compared with the method provided, the selected raw materials and operating conditions are different, and the adaptability of the method under different raw materials and operating conditions is mainly investigated.

[0065] Table 2 Chemical composition of the brine from the Jinel Salt Lake in Dongtai, Qaidam Basin, Qinghai Province

[0066]

[0067] ⑴ Extract 1.00m 3 Table 2 Extract potassium and old brine, add fly ash at 1% of the weight of the old brine, turn on the stirring, 10 minutes later, use the slurry pump to drive into the plate and frame filter press to filter, obtain the filter residue 38Kg, the first refined filtrate 0.98 m 3 , Control...

Embodiment 3

[0075] The raw material is taken from the old brine after potassium extraction from the Xitaijinel Salt Lake in the Qaidam Basin, Qinghai Province, and has the chemical composition shown in Table 3. From the composition analysis, the water chemical type of the brine system belongs to the magnesium sulfate subtype. This example and the examples 2 Compared with the method provided, the selected raw materials and operating conditions are different, and the adaptability of the method under different raw materials and operating conditions is mainly investigated.

[0076] Table 3 The chemical composition of the brine from the Jinel Salt Lake in Xitai, Qaidam Basin, Qinghai Province

[0077]

[0078] ⑴ Extract 1.00m 3 Table 3 Extract potassium and old brine, add fly ash according to 1% of the weight ratio of the old brine, start stirring, 10 minutes later, use a slurry pump to drive into the plate and frame filter press to filter, obtain the filter residue 44Kg, the refined filtrate is 0.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com