Light-diffusion PP material and preparation method

A light diffusion and light diffusion agent technology, applied in the field of functional polymer materials, can solve the problems of weak impact resistance, lower warpage rate, poor thermal stability, etc., achieve less light loss, improve thermal stability, and increase fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

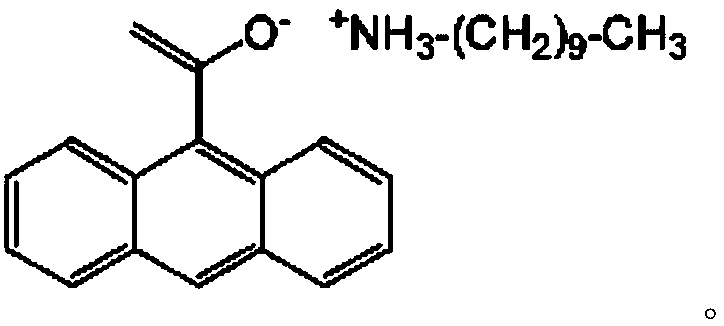

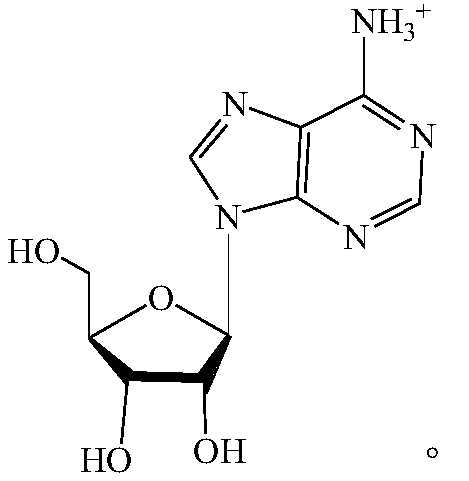

Method used

Image

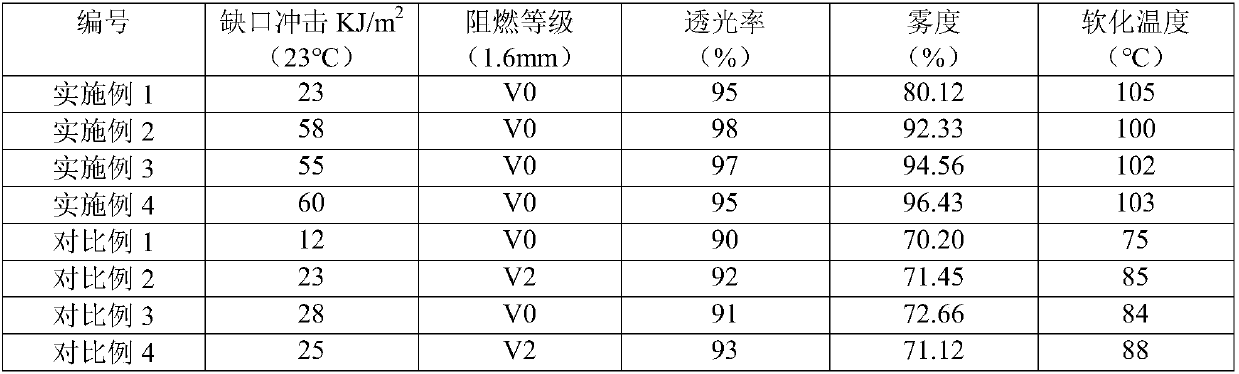

Examples

Embodiment 1

[0039] (1) According to the following ratio, take respectively 90g of polypropylene, 0.2g of light diffusing agent, 0.05g of flame retardant, 0.05g of antioxidant, 0.05g of erucamide and 5g of anti-UV agent; Responsive gel factor coated acrylic resin microspheres, the volume ratio of acrylic resin microspheres to light-responsive gel factor is 20:1; the flame retardant is polycaprolactone modified ammonium polyphosphate, polycaprolactone The molecular weight of the ester is 500g / mol;

[0040] (2) The above-mentioned raw materials are mixed to obtain a mixed material, which is then melt-extruded and granulated to obtain a light-diffusing PP material.

Embodiment 2

[0042] (1) Weigh each raw material for later use, uniformly disperse acrylic resin microspheres with a particle size of 6-15 μm in the light-responsive gel factor suspension under dark conditions, let stand, dry, and acrylic resin microspheres and light The volume ratio of the responsive gel factor is 5:1, and the surface of the acrylic resin microspheres is coated with the photoresponsive gel factor to obtain the first light diffusing agent;

[0043](2) After mixing the first light diffusing agent with 98g polypropylene, add 1g antioxidant, 1g ethylene bis stearamide EBS, 3g nucleoside modified ammonium polyphosphate and 0.5g anti-UV agent in turn to obtain the mixed material ;

[0044] (3) Add acrylic resin microspheres with a particle size of 3 to 5 μm in the mixture, mix evenly, melt extrude, and granulate to obtain pellets;

[0045] (4) The granules are evenly dispersed in the light-responsive gel factor suspension under dark conditions, left to stand, and dried. The vol...

Embodiment 3

[0049] (1) Weigh each raw material for later use, uniformly disperse acrylic resin microspheres with a particle size of 6-15 μm in the light-responsive gel factor suspension under dark conditions, let stand, dry, and acrylic resin microspheres and light The volume ratio of the responsive gel factor is 15:1, and the surface of the acrylic resin microsphere is coated with the photoresponsive gel factor to obtain the first light diffusing agent;

[0050] (2) After the first light diffusing agent is mixed with 95g polypropylene, add 0.5g antioxidant, 0.5g silicone, 2g polycaprolactone modified ammonium polyphosphate (the molecular weight of polycaprolactone is 10000g / mol) ) and 3g anti-UV agent to obtain mixed material;

[0051] (3) Add acrylic resin microspheres with a particle size of 3 to 5 μm in the mixture, mix evenly, melt extrude, and granulate to obtain pellets;

[0052] (4) The granules are uniformly dispersed in the light-responsive gel factor suspension under dark cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com