Moisture-curable type organosilicon-modified flame-retardant polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the field of structural adhesives, can solve the problems of reducing the chemical resistance of polyurethane hot-melt adhesive coatings, solve solvent resistance, improve flame retardancy and adhesion , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

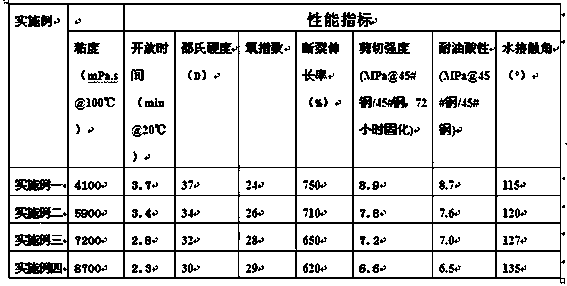

Examples

Embodiment 1

[0026] It is a moisture-curing silicone-modified flame-retardant polyurethane hot-melt adhesive, which is prepared by the following steps:

[0027] Step 1 Synthesis of hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer

[0028] 7 parts of methacryloxypropyl monoblocked dimethyl polysiloxane MAPDMS, 10 parts of methyl methacrylate MMA, 20 parts of butyl acrylate BA and 8 parts of 2-methyl-2 -Acrylic acid-2-hydroxyethyl ester phosphate HMP was dissolved in 50 parts of toluene, controlled at 60°C, and under nitrogen protection, 2.4 parts of thermal initiator 4,4'-azobis(4-cyano Pentanol), polymerized for 5 hours, and after the toluene was removed by rotary evaporation, a hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer was obtained, and the number-average molecular weight of the hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer was 11000, whose c...

Embodiment 2

[0032] It is a moisture-curing silicone-modified flame-retardant polyurethane hot-melt adhesive, which is prepared by the following steps:

[0033] Step 1 Synthesis of hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer

[0034] 13 parts of methacryloxypropyl monoblocked dimethyl polysiloxane MAPDMS, 25 parts of methyl methacrylate MMA, 10 parts of butyl acrylate BA and 15 parts of 2-methyl-2- Acrylic acid-2-hydroxyethyl ester phosphate HMP was dissolved in 80 parts of toluene, controlled at 65°C, under nitrogen protection, added 1.5 parts of thermal initiator 4,4'-azobis(4-cyanopentyl Alcohol), polymerization reaction for 14 hours, after removing toluene by rotary evaporation, obtain hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer, the number-average molecular weight of hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer is 23000 , its chemical...

Embodiment 3

[0038] It is a moisture-curing silicone-modified flame-retardant polyurethane hot-melt adhesive, which is prepared by the following steps:

[0039] Step 1 Synthesis of hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer

[0040] 15 parts of methacryloxypropyl monoblocked dimethyl polysiloxane MAPDMS, 25 parts of methyl methacrylate MMA, 15 parts of butyl acrylate BA and 20 parts of 2-methyl-2- Acrylic acid-2-hydroxyethyl ester phosphate HMP was dissolved in 90 parts of toluene, controlled at 75°C, under the protection of nitrogen, 0.5 parts of thermal initiator 4,4'-azobis(4-cyanopentyl) was added alcohol), polymerized for 10 hours, and removed toluene by rotary evaporation to obtain a hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer, and the number-average molecular weight of the hydroxyl-terminated phosphorus-containing flame-retardant polyorganosilicon acrylate copolymer was 33,000 , i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com