Poly-ether-ether-ketone alveolar bone repairing material and individualization producing method

A technology for repairing materials and manufacturing methods, applied in the fields of polymer materials and biomedical engineering, can solve the problems of lack of long-term fusion of implants and oral tissues, and achieve the effects of good biocompatibility, high accuracy, and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

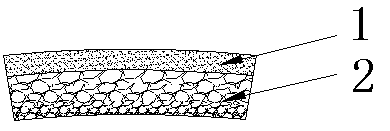

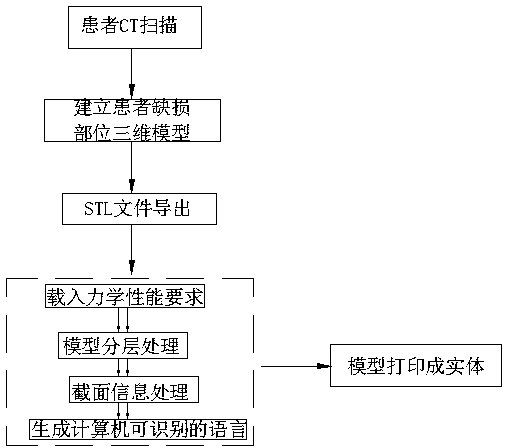

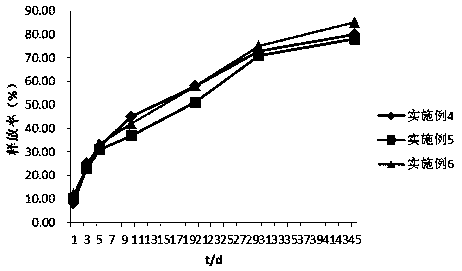

Embodiment 1

[0029] Use computer tomography technology to scan the patient's oral defect, import the 3D modeling software according to the patient's CT or MRI format file, and combine the computer-aided design software to reconstruct the 3D model of the patient's oral defect, and build a more close-fitting model based on the 3D model of the defect. The three-dimensional model of the patient's alveolar bone anatomy was designed, and the dense layer was designed to be 0.8mm thick, and the loose layer was designed to be 0.5mm thick. %, the pore diameter near the inside is 50-80μm, and the porosity is 50%-60%. Generate STL files, write data processing software for the alveolar bone, and process the STL files in layers, process cross-section information, and generate computer-recognized language; set the printing speed to 2mm / s, and the printing layer thickness to 0.12mm . Lay pure PEEK material on the substrate of the printing platform, use the high energy of the laser to sinter and shape the...

Embodiment 2

[0031] Use computerized tomography to scan the patient's oral defect, import the 3D modeling software based on the patient's CT or MRI format file, and combine with computer-aided design software to reconstruct the 3D model of the patient's oral defect to establish a more suitable alveolar bone anatomy The three-dimensional model of the shape, and the dense layer is designed to be 0.5mm thick, and the loose layer is designed to be 1mm thick. The pores near the outer end of the loose layer are 30-40μm in diameter, and the porosity is 50%-60%. 70-80μm, the porosity is set to 80-85%. Generate STL files, write data processing software for the alveolar bone, and process the STL files in layers, process cross-section information, and generate computer-recognized language; set the printing speed to 5mm / s, and the printing layer thickness to 0.2mm . Lay the nmHA / PEEK composite material composed of PEEK and hydroxyapatite at a ratio of 1:1 on the substrate of the printing platform, us...

Embodiment 3

[0035] Use computerized tomography to scan the patient's oral defect, import the 3D modeling software based on the patient's CT or MRI format file, and combine with computer-aided design software to reconstruct the 3D model of the patient's oral defect to establish a more suitable alveolar bone anatomy The three-dimensional model of the shape, and the dense layer is designed to be 0.5mm thick, and the loose layer is designed to be 1mm thick. The pores near the outer end of the loose layer are 50-70μm in diameter, and the porosity is 60%-65%. 80-100μm, porosity 80%-85%. Generate STL files, write data processing software for the alveolar bone, and process the STL files in layers, process cross-section information, and generate computer-recognized language; set the printing speed to 2mm / s, and the printing layer thickness to 0.12mm . Lay the nmHA / PEEK composite material composed of PEEK and hydroxyapatite according to PEEK: nmHA=80wt%:20wt% on the substrate of the printing platf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com