Nanofiber molecularly imprinted membrane with high selectivity for putrescine and preparation method thereof

A molecularly imprinted membrane and nanofiber technology, applied in the field of functional polymer materials, can solve the problems of low sensitivity and response rate, difficulty in obtaining accessibility and permeability, etc., and achieve simple preparation process, good selective adsorption capacity, no Effects of Poison and Potential Biological Traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

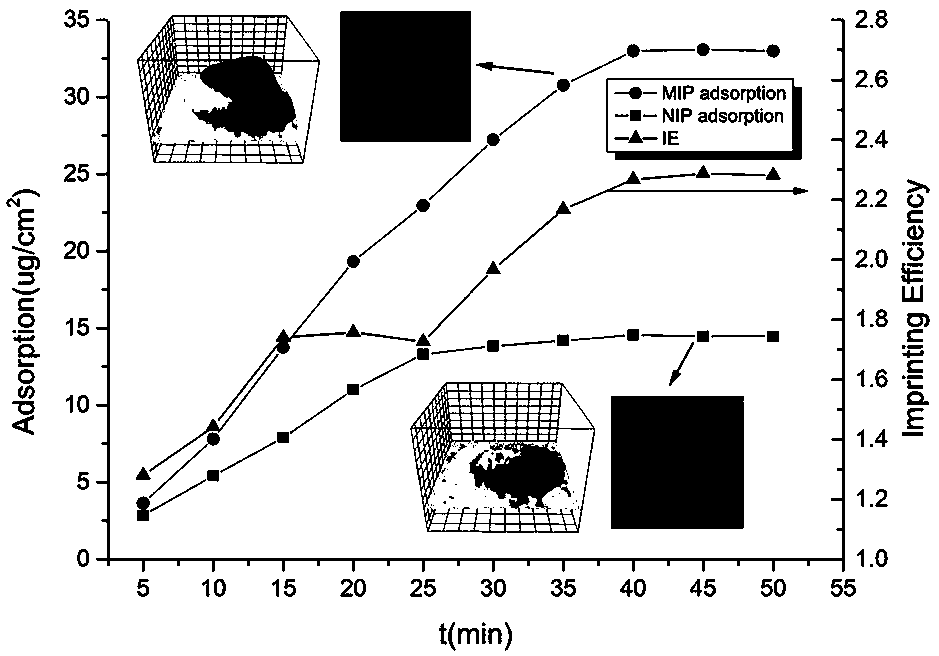

Image

Examples

Embodiment 1

[0029] (1) Dissolve 3 g of polyvinyl alcohol (PVA) in 26.955 mL of deionized water at 90 °C, then add 0.045 mg of 1,4-butanediol (BDO) template at 70 °C, stir to dissolve, and obtain spinning liquid;

[0030] (2) Draw 5 mL of the spinning solution obtained in (1) with a 20 mL syringe, and put it on a 21 # Then put the syringe with the spinning solution in the electrospinning machine for spinning, the spinning conditions are: positive voltage: 15Kv; spinning distance: 15 cm; drum speed: 600 r / min; Filament temperature: 20-27 ℃, spinning humidity: 50-68% and spinning for 2 h to prepare nanofiber membrane material;

[0031] (3) Remove the nanofiber membrane obtained in (2), cut it into 3 mm×3 mm fiber blocks with a blade, and then dry them in an oven at 60°C;

[0032] (4) Add 10 mL of methanol to the dried fiber block for standing elution, change the eluent once, the first time for 6 hours, and then soak for 2 hours, finally take it out and let it dry at room temperature, then ...

Embodiment 2

[0046] (1) Dissolve 3 g of polyvinyl alcohol (PVA) in 26.925 mL of deionized water at 90 °C, then add 0.075 mg of 1,4-butanediol (BDO) template at 70 °C, stir to dissolve, and obtain spinning liquid;

[0047] (2) Draw 5 mL of the spinning solution obtained in (1) with a 20 mL syringe, and put it on a 21 # Then put the syringe with the spinning solution in the electrospinning machine for spinning. The spinning conditions are: positive voltage: 15Kv; spinning distance: 15 cm; drum speed: 600 r / min; Filament temperature: 20-27 ℃, spinning humidity: 50-68% and spinning for 2 h to prepare nanofiber membrane material;

[0048] (3) Remove the nanofiber membrane obtained in (2), cut it into 3 mm×3 mm fiber blocks with a blade, and then dry them in an oven at 60°C;

[0049] (4) Add 10 mL of methanol to the dried fiber block for static elution, change the eluent once for 6 hours, then soak for 2 hours, finally take it out and let it evaporate and dry at room temperature, then add 315 ...

Embodiment 3

[0052] (1) Dissolve 3 g of polyvinyl alcohol (PVA) in 26.925 mL of deionized water at 90 °C, then add 0.075 mg of 1,4-butanediol (BDO) template at 70 °C, stir to dissolve, and obtain spinning liquid;

[0053] (2) Draw 5 mL of the spinning solution obtained in (1) with a 20 mL syringe, and put it on a 21 # Then put the syringe with the spinning solution in the electrospinning machine for spinning. The spinning conditions are: positive voltage: 15Kv; spinning distance: 15 cm; drum speed: 600 r / min; Filament temperature: 20-27 ℃, spinning humidity: 50-68% and spinning for 2 h to prepare nanofiber membrane material;

[0054] (3) Remove the nanofiber membrane obtained in (2), cut it into 3 mm×3 mm fiber blocks with a blade, and then dry them in an oven at 60°C;

[0055] (4) Add 10 mL of methanol to the dried fiber block for standing elution, change the eluent once for 6 hours, then soak for 2 hours, take it out and let it dry at room temperature, then add 290 μL dropwise 0.984 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com