Preparation method and application of 1T phase molybdenum disulfide supported titanium dioxide nanotube array

A nanotube array and titanium dioxide technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor degradation of antibiotic wastewater and achieve Improve electron transmission efficiency, improve absorption capacity, and purify water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

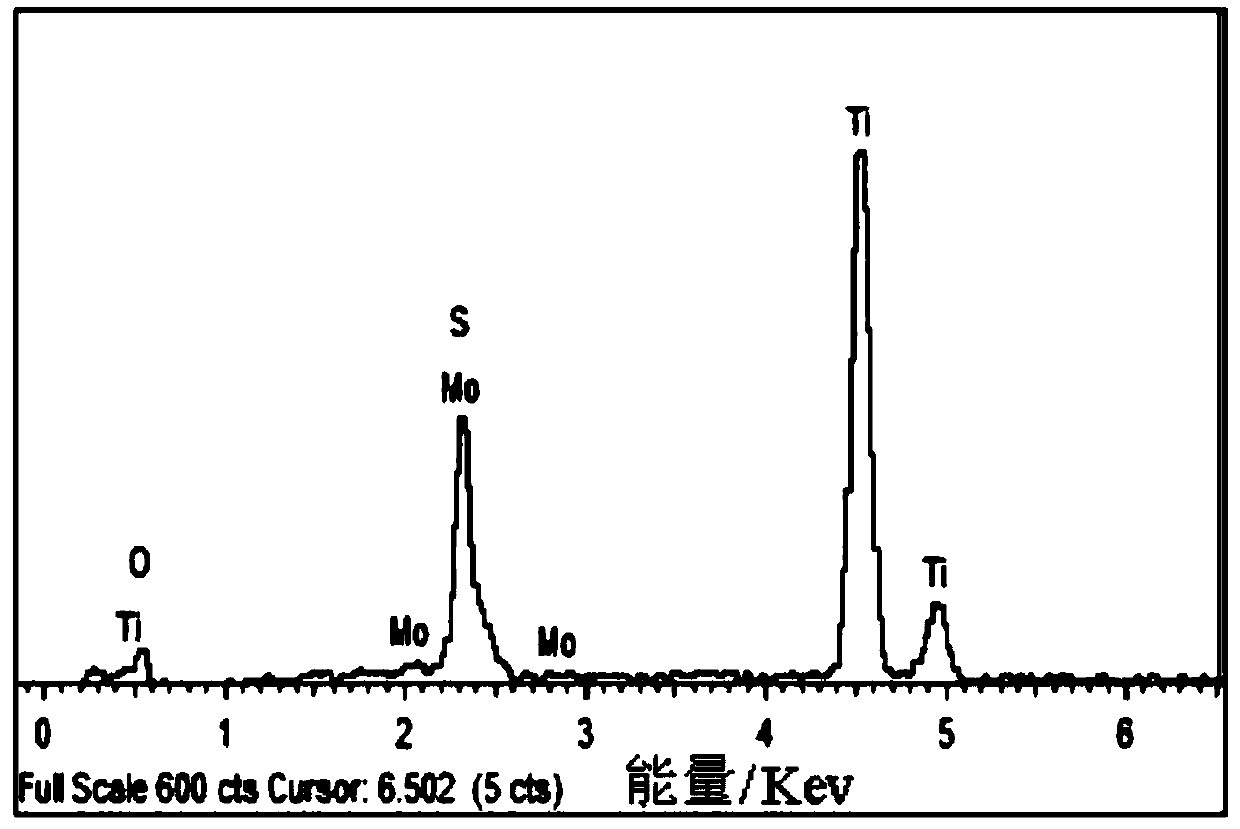

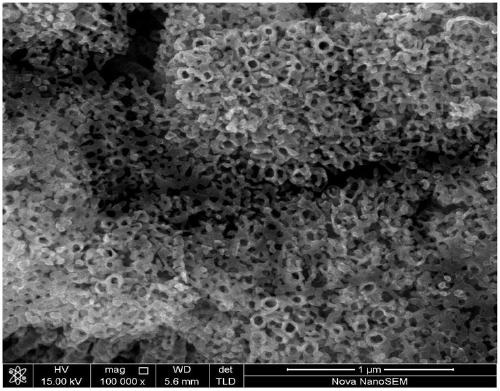

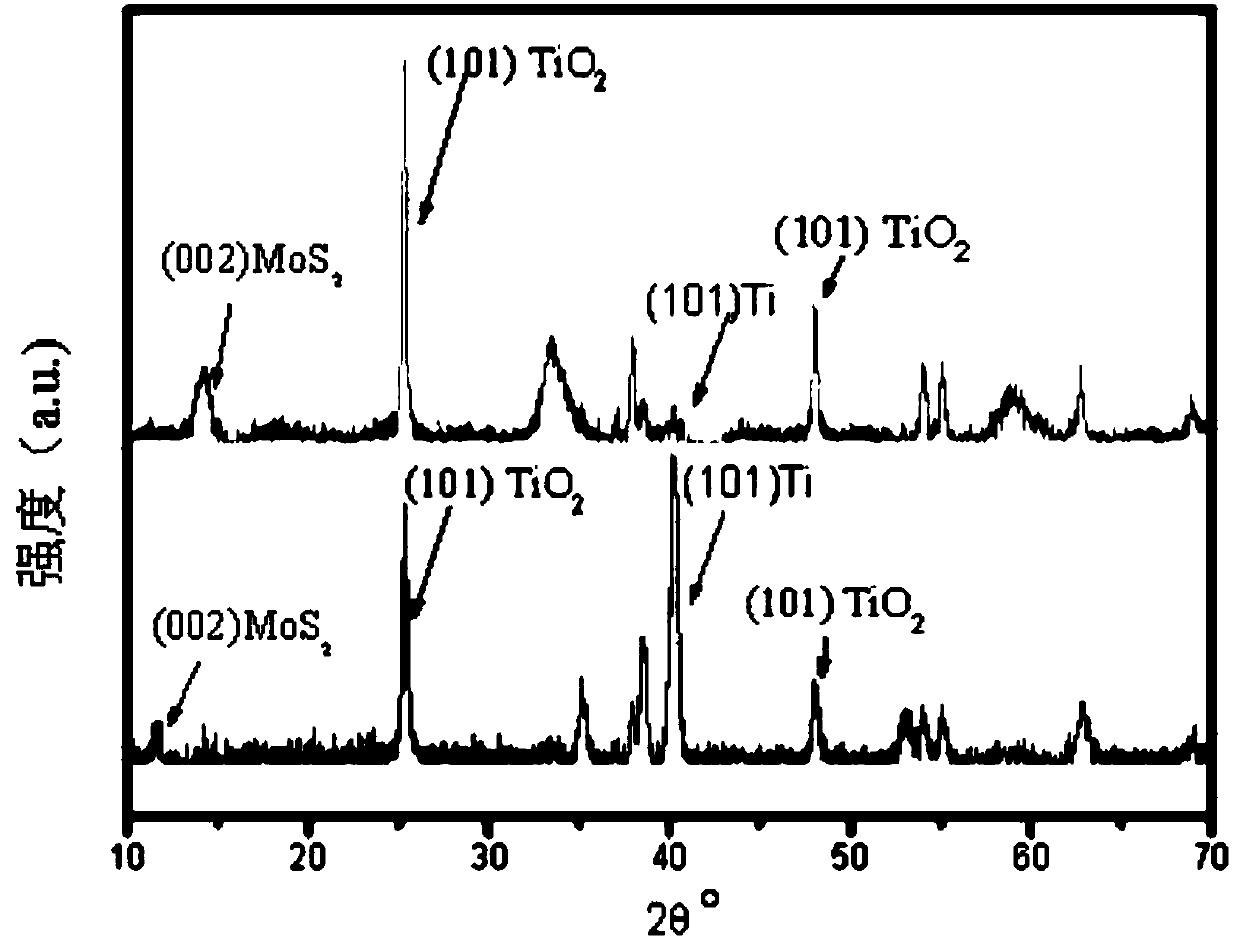

[0023] Specific embodiment 1: This embodiment is a method for preparing a 1T phase molybdenum disulfide-supported titanium dioxide nanotube array, which is specifically carried out according to the following steps:

[0024] 1. Prepare titanium wire: Wind the titanium wire into a spiral shape, then ultrasonically clean it with acetone, ethanol and deionized water for 0.5h to 1h respectively, and finally place it in a drying oven to dry;

[0025] 2. Place the dried titanium wire in step 1 as the anode in the electrolytic cell, and the platinum mesh as the cathode in the electrolytic cell; the solute of the electrolyte is hydrofluoric acid, the solvent is dimethyl sulfoxide, and the hydrogen fluoride in the electrolyte is The mass fraction of the acid is 2% to 3%; it is oxidized at room temperature and under the condition of a constant voltage of DC power supply of 30V to 35V for 8h to 10h. After the oxidation is completed, it is taken out and dried to obtain an amorphous form bas...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the titanium wire is wound into a spiral shape, and then ultrasonically cleaned with acetone, ethanol and deionized water for 0.5h respectively, and finally placed in a drying box dry. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the solute of the electrolytic solution described in step one is hydrofluoric acid, the solvent is dimethyl sulfoxide, the quality of hydrofluoric acid in the electrolytic solution The score is 2%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com