Sulfur-tolerant shift methanation integrated catalyst and preparation method thereof

A sulfur-resistant shift, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as retention, unindustrial application, etc. Low cost, low preparation cost, and the effect of increasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

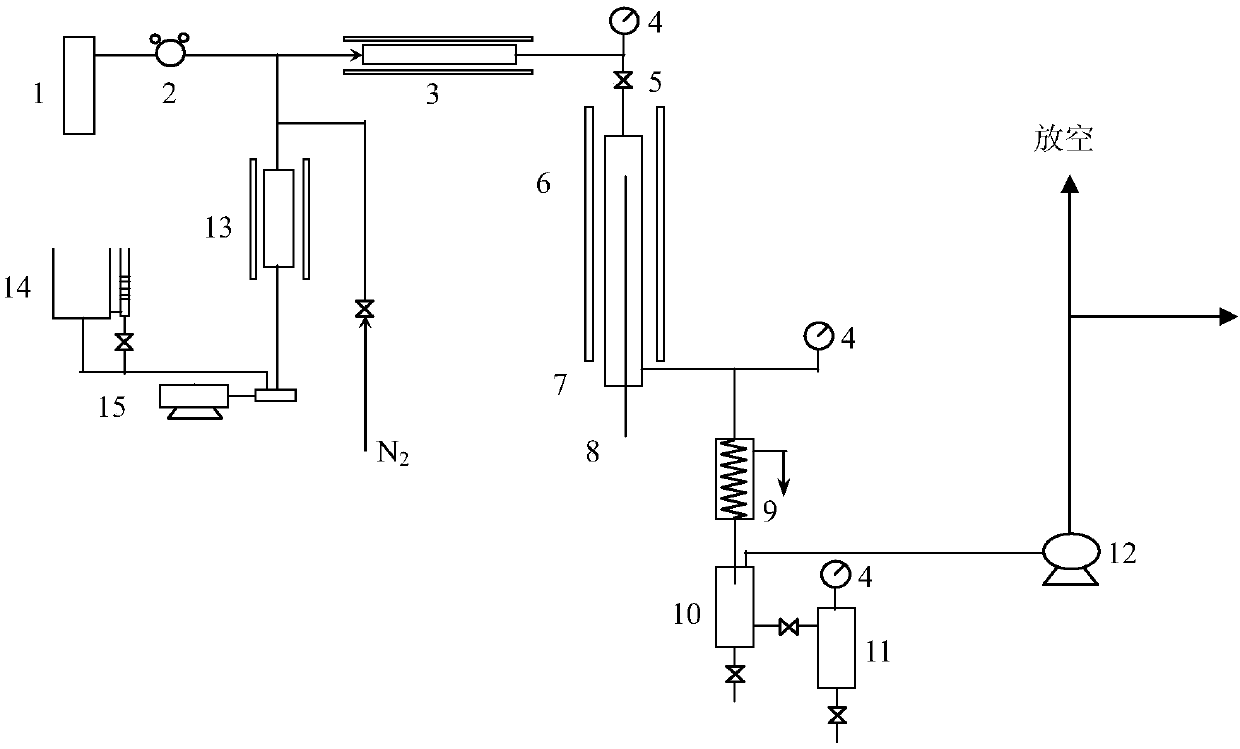

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 15.8 g of ammonium heptamolybdate with 40 mL of deionized water to obtain a clear solution A.

[0032] (2) Add 7.8g of cobalt nitrate, 4.6g of cerium nitrate, 3g of oxalic acid and 1mL of dilute nitric acid into 15mL of deionized water respectively to obtain solution B;

[0033] (3) Dry mix 98g of metatitanic acid, 14g of 80# calcium aluminate, and 3g of Tianqing powder, add solutions A and B respectively, knead evenly, form, dry naturally, and roast at 550°C to prepare a semi-finished catalyst.

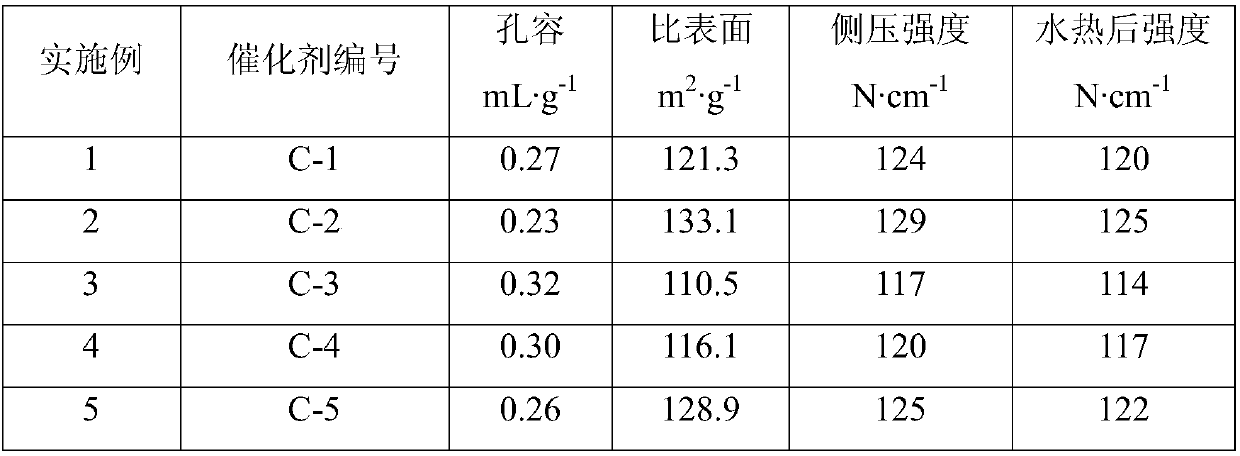

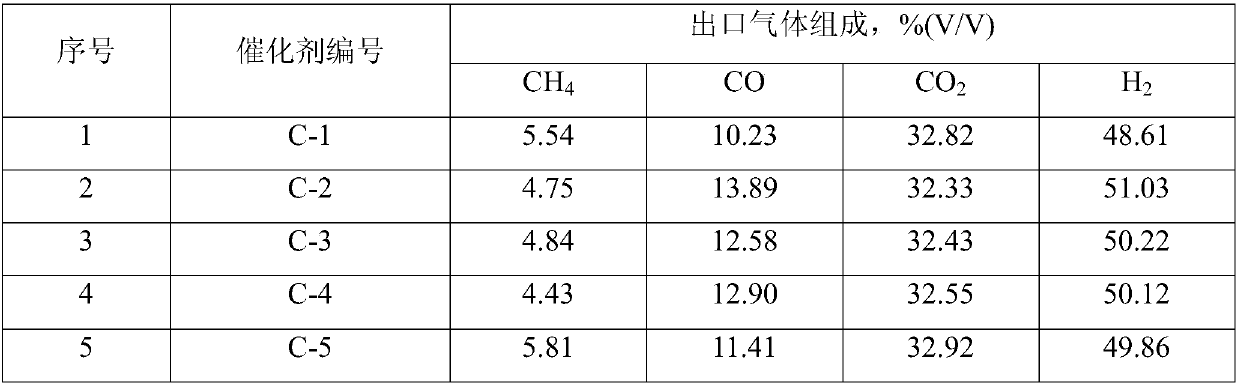

[0034] (4) place the catalyst semi-finished product in the airtight reactor, with 500h -1 Air mixture containing 0.2% hydrogen sulfide was introduced at space velocity and maintained at 200°C for 10 hours, and then the temperature was lowered to room temperature to obtain finished catalyst C1. Its strength, pore structure and catalytic activity data are shown in Tables 1 and 2.

Embodiment 2

[0036] (1) Dissolve 18.5 g of ammonium tetramolybdate with 50 mL of deionized water to obtain clear solution A.

[0037] (2) Add 2.2g of cobalt nitrate, 2.5g of lanthanum nitrate, and 4g of citric acid into 15mL of deionized water to obtain solution B;

[0038] (3) Dry mix 75.6g of metatitanic acid, 30g of 85# calcium aluminate, and 2g of starch, add solutions A and B respectively, knead evenly, shape, dry naturally, and roast at 700°C to obtain a semi-finished catalyst.

[0039] (4) place the catalyst semi-finished product in the airtight reactor, with 1000h -1 Air mixture containing 0.1% hydrogen sulfide was introduced at space velocity and maintained at 150° C. for 15 hours, and then the temperature was lowered to room temperature to obtain finished catalyst C2. Its strength, pore structure and catalytic activity data are shown in Tables 1 and 2.

Embodiment 3

[0041] (1) Dissolve 9.8 g of ammonium heptamolybdate with 35 mL of deionized water to obtain a clear solution A.

[0042] (2) Add 16.0 g of cobalt nitrate, 3.6 g of yttrium nitrate, 3 g of oxalic acid and 2 mL of acetic acid into 20 mL of deionized water respectively to obtain solution B.

[0043] (3) Dry mix 74g of anatase, 13g of 75# calcium aluminate, and 6g of Tianqing powder, add solutions A and B respectively, knead evenly, form, dry naturally, and roast at 650°C to obtain a semi-finished catalyst.

[0044] (4) place the catalyst semi-finished product in the airtight reactor, with 200h -1 Air mixture containing 0.3% hydrogen sulfide was introduced at space velocity, maintained at 150°C for 20 hours, and then the temperature was lowered to room temperature to obtain finished catalyst C3. Its strength, pore structure and catalytic activity data are shown in Tables 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com