Heat absorbing coating material for solar panel heat collector

A technology for solar panels and heat-absorbing coatings, applied in radiation-absorbing coatings, anti-corrosion coatings, epoxy resin coatings, etc. The effect of photothermal conversion efficiency, outstanding thermal stability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

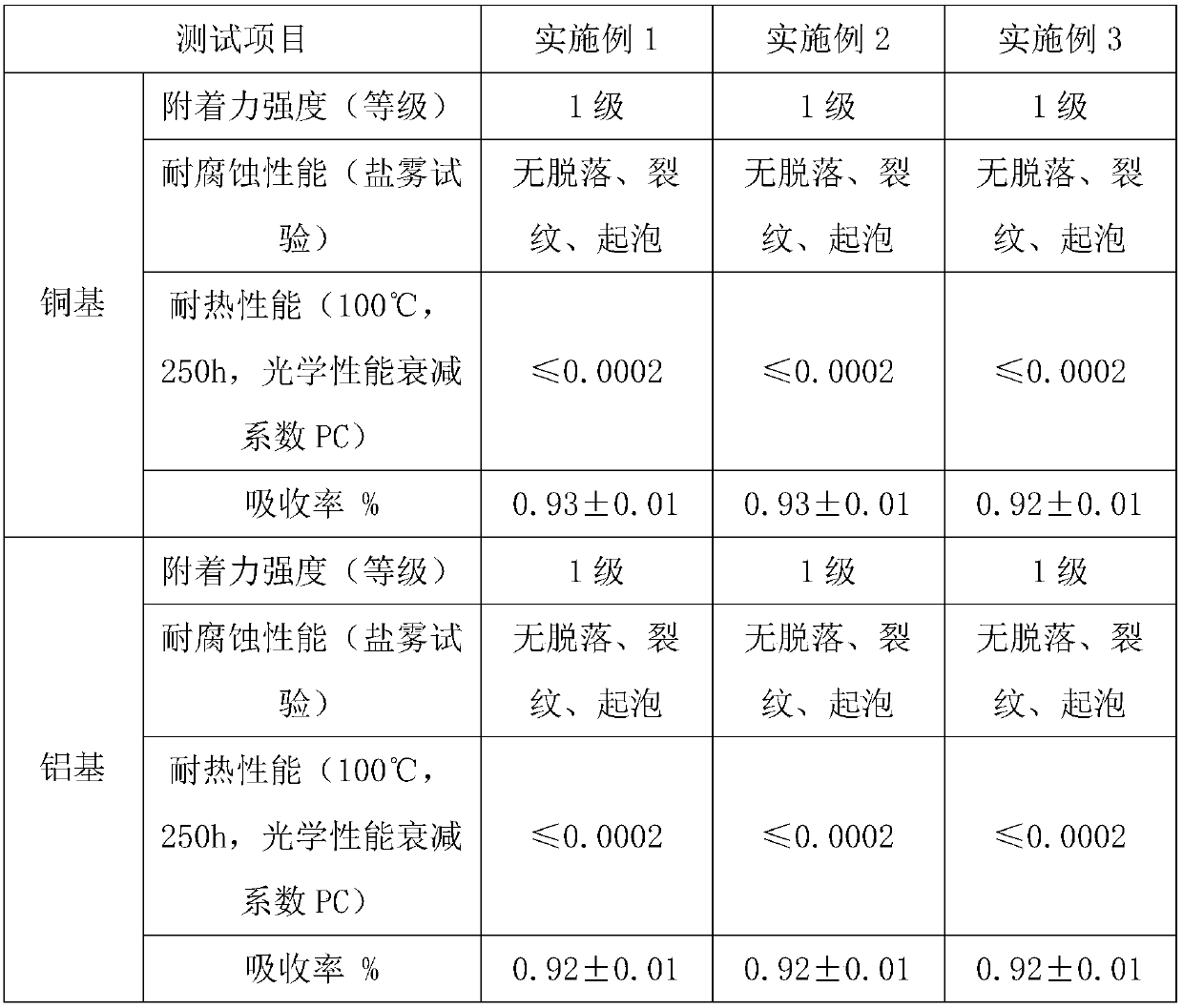

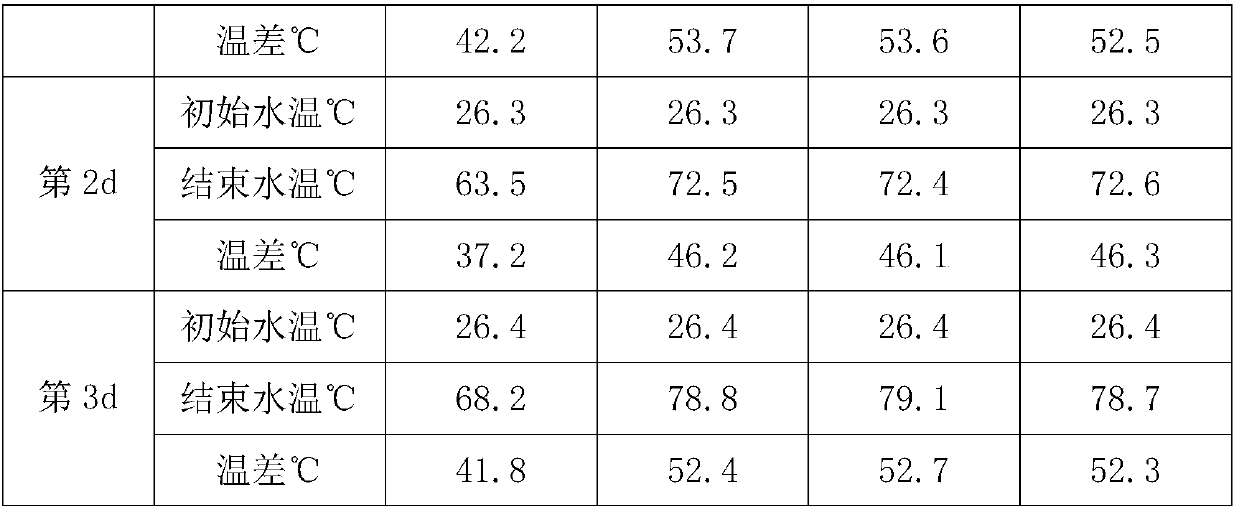

Examples

Embodiment 1

[0028] A heat-absorbing coating for a solar panel heat collector. According to the mass percentage, the components of the heat-absorbing coating include: 30% of a heat-absorbing agent, 15% of a cured resin, 2% of a film-forming aid, and the balance being a solvent;

[0029] Wherein, the endothermic agent is a solid mixture after photothermal sensitization treatment, and the method of photothermal sensitization treatment includes the following steps:

[0030] (1) Evenly ball-milling the heat-absorbing agent components, respectively using acetone solvent and deionized water to carry out circular cleaning;

[0031] (2) Add the cleaned endothermic agent into the photothermosensitization A liquid according to the solid-to-liquid ratio of 1:5, and add 0.7wt% of sulfamic acid accounting for the mass of the endothermic agent to the photothermosensitization A liquid at the same time Acid and 2.5wt% KBM-403 silane coupling agent, uniformly dispersed and soaked for 45 minutes, after the ...

Embodiment 2

[0045] A heat-absorbing coating for a solar panel heat collector. According to the mass percentage, the components of the heat-absorbing coating include: 35% of a heat-absorbing agent, 25% of a cured resin, 6% of a film-forming aid, and the balance being a solvent;

[0046] Wherein, the endothermic agent is a solid mixture after photothermal sensitization treatment, and the method of photothermal sensitization treatment includes the following steps:

[0047] (1) Evenly ball-milling the heat-absorbing agent components, respectively using acetone solvent and deionized water to carry out circular cleaning;

[0048] (2) Add the cleaned endothermic agent into the photothermosensitization A liquid according to the solid-to-liquid ratio of 1:5, and add 0.7wt% of sulfamic acid accounting for the mass of the endothermic agent to the photothermosensitization A liquid at the same time Acid and 2.5wt% KBM-403 silane coupling agent, uniformly dispersed and soaked for 60 minutes, after the so...

Embodiment 3

[0062] A heat-absorbing coating for a solar panel heat collector. According to the mass percentage, the components of the heat-absorbing coating include: 33% of heat-absorbing agent, 20% of cured resin, 4% of film-forming auxiliary agent, and the balance is solvent;

[0063] Wherein, the endothermic agent is a solid mixture after photothermal sensitization treatment, and the method of photothermal sensitization treatment includes the following steps:

[0064] (1) Evenly ball-milling the heat-absorbing agent components, respectively using acetone solvent and deionized water to carry out circular cleaning;

[0065] (2) Add the cleaned endothermic agent into the photothermosensitization A liquid according to the solid-to-liquid ratio of 1:5, and add 0.7wt% of sulfamic acid accounting for the mass of the endothermic agent to the photothermosensitization A liquid at the same time Acid and 2.5wt% KBM-403 silane coupling agent, uniformly dispersed and soaked for 55 minutes, after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com