A biochar-based immobilized microbial agent and its preparation method and application

A technology for immobilizing microorganisms and biochar, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of cumbersome operation of modified biochar carriers, high cost, and easy obstruction of contact between bacterial strains and pollutants , to achieve the effect of less loss, high degradability and favorable preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Fermentation of Mycobacterium sp.CSC-6

[0047] Use an inoculation loop to pick a ring of strains from the LB solid plate of Mycobacterium sp.CSC-6 and inoculate it in 5mL of 1# liquid medium (peptone 10.0g, yeast powder 5.0g, sodium chloride 10.0g, deionized water 1000mL, pH 7.2-7.4), activate for 48h at 30°C in a shaking incubator with a rotation speed of 120r / min.

[0048] Take 8 mL of the activated CSC-6 bacterial solution and add it to 400 mL of 2# liquid medium (glucose 20.0 g, peptone 20.0 g, yeast powder 10.0 g, crude oil 2.0 g, deionized water 1000 mL, pH 7.2-7.4), Expand the culture in a shaking incubator at 30°C with a rotational speed of 120r / min for 48h to obtain seed liquid.

[0049] Take 400mL of seed liquid and add it to a fermenter with 3.6L of 2# liquid medium. The culture conditions are: ventilation ratio 0.5vvm, stirring speed 200r / min, temperature 30°C, pH 7.2-7.4, fermentation time 48h. After the fermentation finishes, centrifuge on a high-speed ...

Embodiment 2

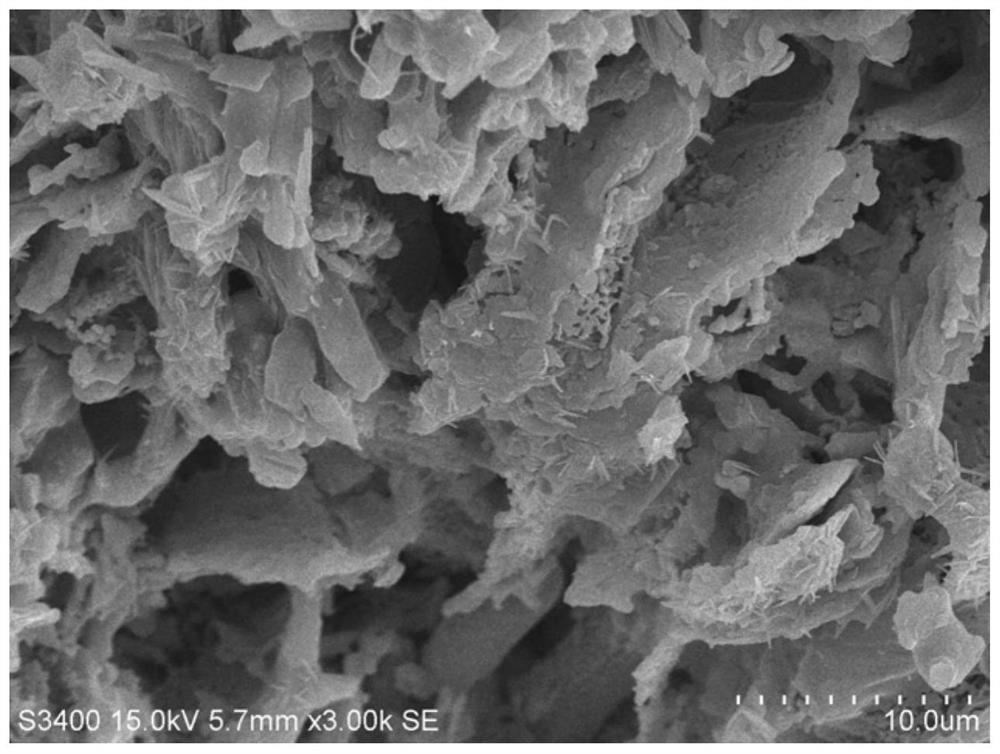

[0051] Weigh 1.0g of 1# bacterial agent and add it into 1000mL of 3# liquid medium (5.0g of sucrose, 3.0g of beef extract, 1.0g of yeast powder, 1000mL of deionized water, 2.0g of petroleum, pH 7.2-7.4), at 30 ℃, in a shaking incubator with a rotational speed of 120r / min for 4 hours, then add 100g of biochar carrier, the microstructure of the biochar carrier is as follows: figure 1 As shown, after continuing to shake for 24 hours, use a disc centrifuge to remove excess 3# liquid medium to obtain 2# bacterial agent.

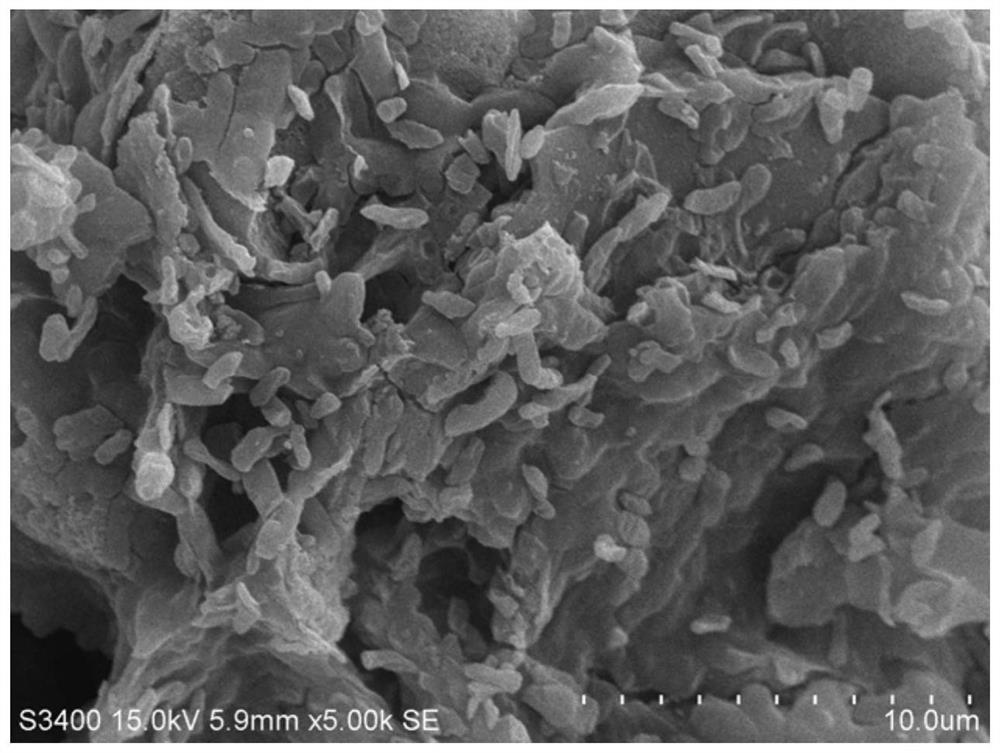

[0052] Add 50g of nutrient solution (oleic acid 0.4mL, glycerol 1.0g, sodium citrate 0.2g, disodium hydrogen phosphate 1.0g, potassium dihydrogen phosphate 1.0g, ammonium sulfate 0.5g, zinc sulfate 0.5mg, calcium chloride 0.5 mg, copper sulfate 0.5mg, magnesium sulfate 15.0mg) in 2# microbial agent, after 2h of adsorption, put in freeze dryer to remove excess water, get 3# bacterial agent. Microscopic picture of 3# bacterial agent figure 2 shown.

Embodiment 3

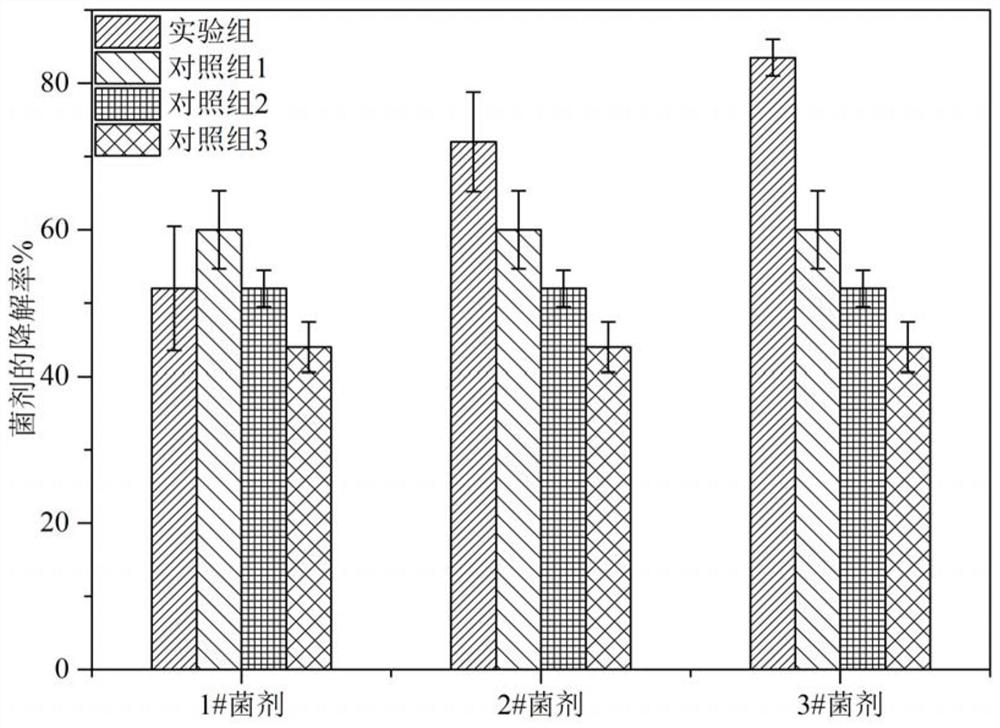

[0054] Degradation performance of biochar-based composite bacterial agents

[0055] The 1# bacterial agent, 2# bacterial agent, and 3# bacterial agent prepared in Examples 1 and 2 were used to carry out experiments on degrading petroleum pollutants in water bodies respectively. Prepare the inorganic salt medium (1.00g / L NH 4 Cl, 0.05g / L CaCl 2 , 0.10g / LMgSO 4 .7H 2 O, 1.00g / L K 2 HPO 4 , 1.00g / L KH 2 PO 4 ) 100mL, add 1# bacterial agent 0.01g to be experimental group 1, add 2# bacterial agent 1.0g to be experimental group 2, add 3# bacterial agent 1.0g to be experimental group 3, add 1.0g biochar + nutrient (oleic acid 0.4mL, glycerin 1.0g, sodium citrate 0.2g, disodium hydrogen phosphate 1.0g, potassium dihydrogen phosphate 1.0g, ammonium sulfate 0.5g, zinc sulfate 0.5mg, calcium chloride 0.5mg, copper sulfate 0.5mg, magnesium sulfate 15.0 mg) was the control group 1, adding 1.0 g of biochar was the control group 2, and no bacterial agent was added as the control grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com