Quasi-solid tungsten trioxide electrochromic device and preparation method thereof

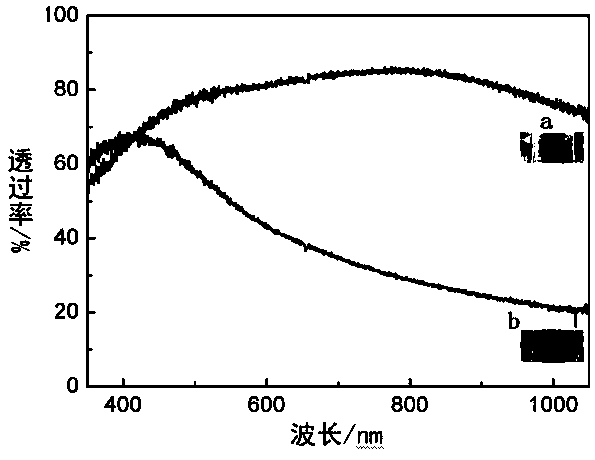

An electrochromic device, tungsten trioxide technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of unobvious optical contrast, poor cycle performance, long response time, etc., achieve simple process and promote commercialization The development, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

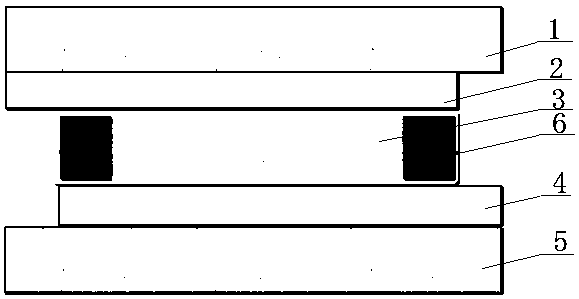

[0042] Example 1 Preparation of electrochromic device

[0043] 1. Preparation of tungsten trioxide working electrode:

[0044] Step a: Take 3.3 g Na 2 WO 4 .2H 2 O was dissolved in 76 mL deionized water, the concentration of sodium tungstate solution was 0.13M, and 2 g (NH 4 ) 2 SO 4 , adding hydrochloric acid to adjust the pH to 2.0.

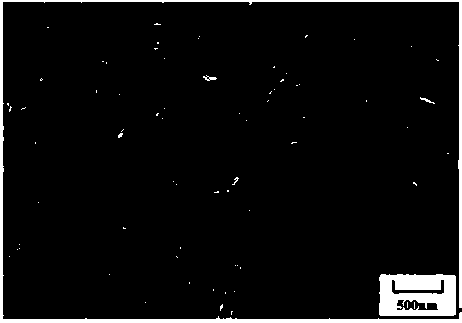

[0045] Step b: Take 60 mL of the solution obtained in step a and place it in a 100 mL reactor, seal it and put it into a blast drying oven for hydrothermal reaction, react at 200 °C for 48 hours, and then dry at 60 °C; obtain WO 3 Nanowire; WO obtained in this step 3 Nanowire scanning electron microscope picture as figure 2 shown, WO 3 The diameter of the nanowire is about 50 nm, which can form a nano-void structure, which is conducive to ion intercalation and extraction, and improves the cycle life of the electrochromic device.

[0046] Step c: Take the WO obtained in step b 3 nanowires, adding isopropanol to form a mixed solution ...

Embodiment 2

[0061] Example 2 Preparation of electrochromic device

[0062] In the preparation method of this example, except for the following steps of preparing the tungsten trioxide working electrode, other steps are the same as in Example 1.

[0063] Preparation of tungsten trioxide working electrode:

[0064] Step a: Take 3.3 g Na 2 WO 4 .2H 2 O was dissolved in 76 mL of deionized water, and hydrochloric acid was added to adjust the pH to 2.0.

[0065] Step b: Take 60 mL of the above solution and place it in a 100 mL reactor, seal it well and put it into a blast drying oven for hydrothermal reaction at a reaction temperature of 200 °C for 48 hours. WO 3 Collect by centrifugation and dry at 60°C.

[0066] Step c: Take the WO obtained in step b 3 , adding isopropanol to form WO 3 A mixed solution with a mass fraction of 0.5% was ultrasonically dispersed for 2 hours to obtain WO 3 Mixed solution, its SEM picture is as follows Figure 5 As shown, it can be seen that without addi...

Embodiment 3

[0069] Example 3 Preparation of electrochromic device

[0070] Except for the following steps of preparing the tungsten trioxide working electrode, other steps are the same as in Example 1.

[0071] Preparation of tungsten trioxide working electrode:

[0072] Step a: Take 3.3 g Na 2 WO 4 .2H2 O was dissolved in 76 mL deionized water, and 2 g (NH 4 ) 2 SO 4 , adding hydrochloric acid to adjust the pH to 2.0.

[0073] Step b: Take 60 mL of the above solution and place it in a 100 mL reactor, seal it well and put it into a blast drying oven for hydrothermal reaction at a reaction temperature of 200 °C for 48 hours. collect WO 3 nanowires, dried at 60 °C.

[0074] Step c: Take the WO obtained in step b 3 For nanowires, add isopropanol to form a mixed solution with a mass fraction of 0.5%, and ultrasonically disperse for 2 hours.

[0075] Step d: Take the solution after ultrasonic dispersion in step c for spraying. The spraying gun model is Taiwan Polaroid spray gun RH-BS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com