Nickel sulfide nanosheet/carbon quantum dot composite material and preparation method and application thereof

A technology of carbon quantum dots and composite materials, which is applied in the field of nickel sulfide nanosheets/carbon quantum dot composite materials, to achieve the effects of low production cost, simple control, and improved rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

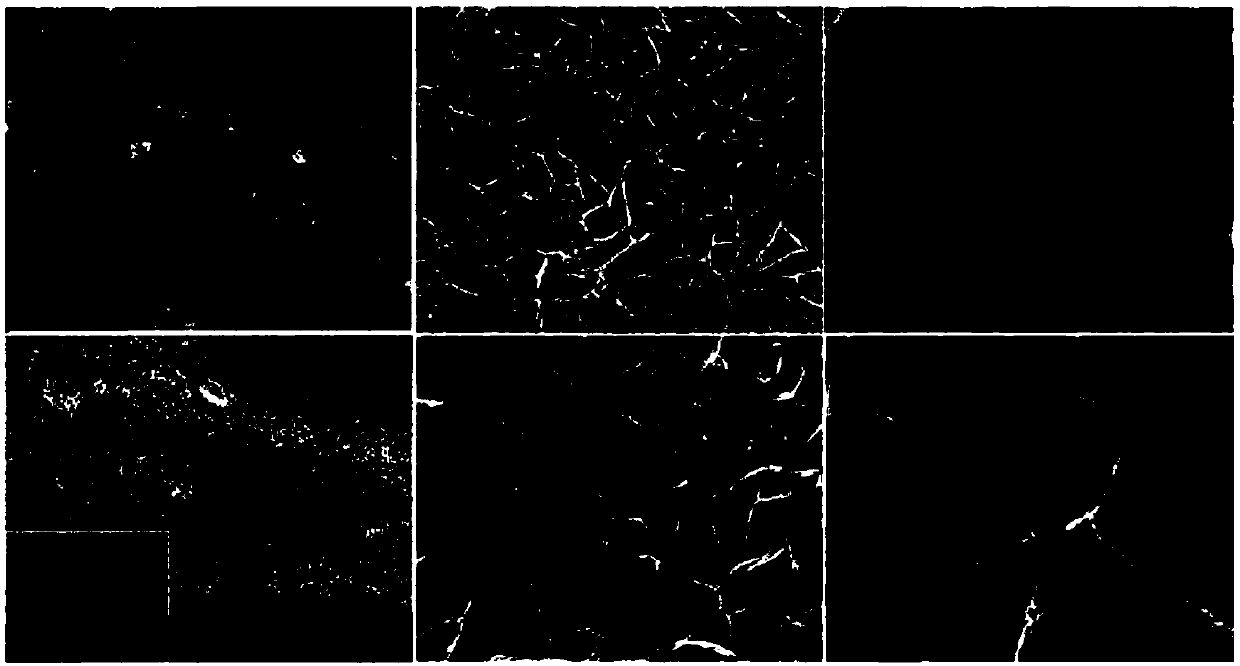

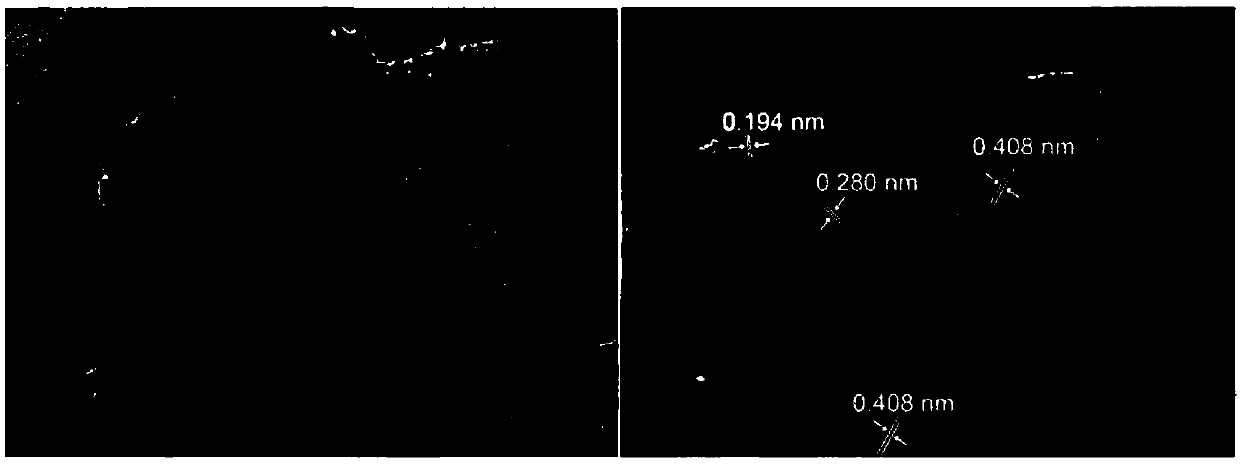

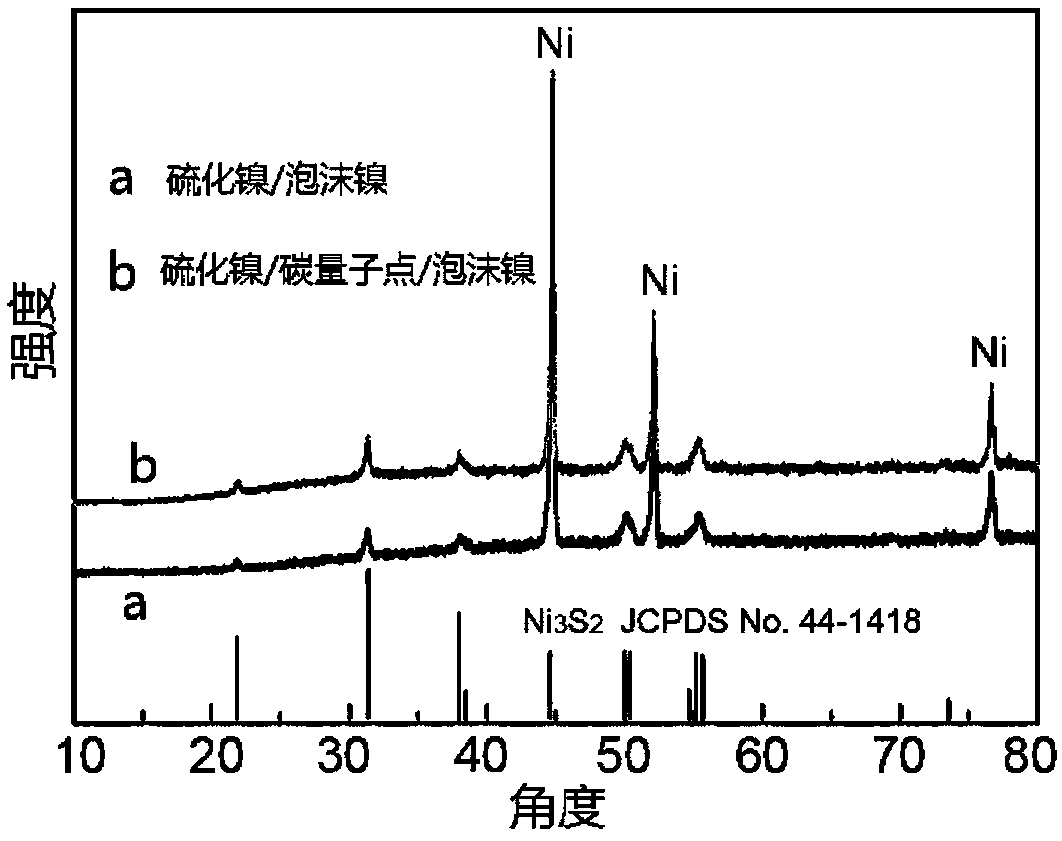

Image

Examples

Embodiment 1

[0034] 1. At room temperature, foam nickel (size: 1*4cm 2 ) into a beaker, followed by ultrasonication with acetone, 0.5mol / L hydrochloric acid, distilled water, and dehydrated ethanol for 20 minutes, dried and weighed for later use;

[0035] 2. Add 5mmol of nickel nitrate and 10mmol of hexamethylenetetramine into 35mL of deionized water and stir for 10min to obtain a mixed solution;

[0036] 3. Put nickel foam (size: 1*4cm 2 ) after immersing in the mixed solution obtained in step 2, ultrasonically for 30 minutes, take out the magnet, and then transfer the above mixed solution and nickel foam to a polytetrafluoroethylene reactor; the reactor is sealed and placed in a blast drying oven, and the reaction condition is 100°C , the reaction time is 10 hours;

[0037] 4. After stopping the reaction and cooling down naturally, take out the sample in the reactor, wash it with a large amount of water, transfer 30mL of 0.1mol / L sodium sulfide solution and nickel foam to the polytetra...

Embodiment 2

[0040] 1. At room temperature, foam nickel (size: 1*4cm 2 ) into a beaker, followed by ultrasonication with acetone, 0.5mol / L hydrochloric acid, distilled water, and absolute ethanol for 20 minutes, dried and weighed for later use;

[0041] 2. Add 5 mmol of nickel nitrate and 10 mmol of hexamethylenetetramine to 35 mL of 1 mg / mL carbon quantum dot mixed solution and stir for 10 minutes to obtain a carbon quantum dot / nickel hydroxide mixture precursor solution;

[0042] 3. Put nickel foam (size: 1*4cm 2 ) after immersing in the carbon quantum dot / nickel hydroxide mixture precursor solution obtained in step 2, ultrasonically for 30 minutes, the magneton was taken out, and then the above-mentioned mixed solution and nickel foam were transferred to a polytetrafluoroethylene reactor; the reactor was sealed and placed in Blast drying oven, react at 100°C for 10 hours;

[0043] 4. After stopping the reaction and cooling down naturally, take out the sample in the reactor, wash it wi...

Embodiment 3

[0047] 1. At room temperature, foam nickel (size: 1*4cm 2 ) into a beaker, followed by ultrasonication with acetone, 0.5mol / L hydrochloric acid, distilled water, and absolute ethanol for 20 minutes, dried and weighed for later use;

[0048] 2. Add 5 mmol of nickel chloride and 10 mmol of hexamethylenetetramine to 35 mL of 1.5 mg / mL carbon quantum dot mixed solution and stir for 10 minutes to obtain a carbon quantum dot / nickel hydroxide mixture precursor solution;

[0049] 3. Put nickel foam (size: 1*4cm 2 ) after immersing in the carbon quantum dot / nickel hydroxide mixture precursor solution obtained in step 2, ultrasonically for 30 minutes, the magneton was taken out, and then the above-mentioned mixed solution and nickel foam were transferred to a polytetrafluoroethylene reactor; the reactor was sealed and placed in Blast drying oven, react at 120°C for 8 hours;

[0050] 4. After stopping the reaction and cooling down naturally, take out the sample in the reactor, wash it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com