Coating method of sodium ion battery positive electrode material and secondary battery thereof

A technology for sodium ion batteries and cathode materials, which is applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of waste liquid, unsatisfactory economy, and unsatisfactory coating effect in the treatment method, and improve the cycle stability. , good coating effect, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

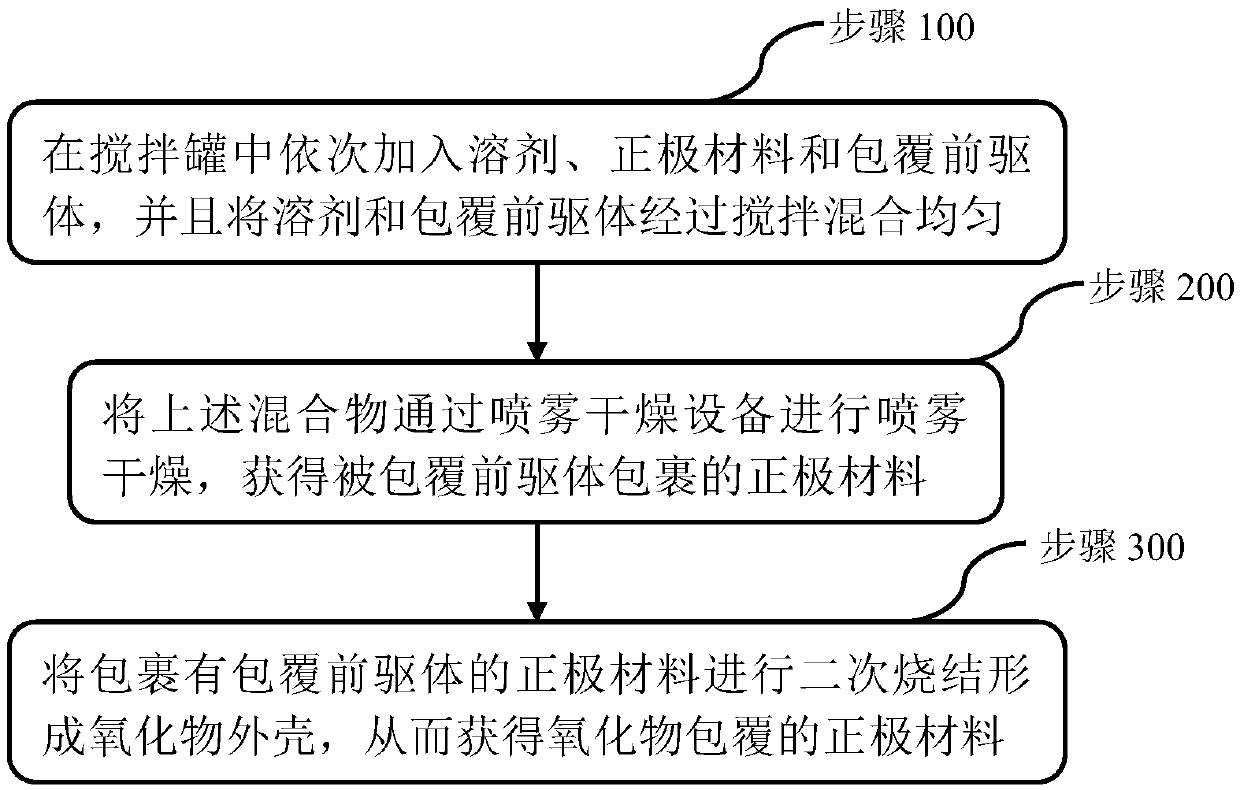

[0032] The invention provides a method for preparing a secondary battery comprising a sodium ion positive electrode material, comprising the following steps:

[0033] Mix the active material of the prepared sodium ion positive electrode material with conductive carbon black and polyvinylidene fluoride binder in a mass ratio of 7:2:1, and add N-methylpyrrolidone solution until it is in a dry environment at room temperature Grinding to form a slurry;

[0034] Apply the prepared slurry evenly on the aluminum foil of the current collector, and cut it into a circular pole piece with a diameter of 12mm after the initial drying;

[0035] The circular pole piece was dried at 120° C. under vacuum for 12 hours and then transferred to a glove box for use.

[0036] In addition, the present invention also provides a sodium ion secondary battery, which comprises the above-mentioned positive electrode material of the sodium ion battery.

[0037] Further, the present invention also provides...

Embodiment 1

[0039] Based on the above coating method, firstly, the positive electrode material is selected as Na 0.9 Cu 0.22 Fe 0.30 mn 0.48 o 2 , which is recorded as raw material 1, and its particle size D50 is 10 μm. The coating precursor is aluminum nitrate, and the solvent is water. Then, put an appropriate amount of water in the mixing tank, gradually add 100kg of positive electrode material and 1kg of coated precursor, fully stir and disperse, and use spray drying equipment for rapid drying, and collect the precursor coated positive electrode material. Finally, the collected positive electrode material is subjected to secondary sintering, the sintering temperature is 700 degrees, and the time is 8 hours, wherein the aluminum nitrate is decomposed into aluminum oxide on the surface of the positive electrode material, that is, the alumina-coated positive electrode material is obtained. , recorded as coating material 1.

[0040]A secondary battery is prepared according to the ab...

Embodiment 2

[0043] Based on the above coating method, firstly, the positive electrode material is selected as Na 1.0 Ni 0.22 Cu 0.11 Fe 0.33 mn 0.33 o 2 , recorded as raw material 2, its particle size D50 is 10 μm, the coating precursor is magnesium oxalate, and the solvent is water. Then, put an appropriate amount of water in the mixing tank, gradually add 100kg of positive electrode material and 2kg of coated precursor, fully stir and disperse, and use spray drying equipment for rapid drying, and collect the precursor coated positive electrode material. Finally, the collected positive electrode material is subjected to secondary sintering, the sintering temperature is 900 degrees, and the time is 6 hours, wherein the magnesium oxalate is decomposed into magnesium oxide on the surface of the material, that is, the positive electrode material coated with magnesium oxide is obtained, which is recorded as Covering material 2.

[0044] A secondary battery is prepared according to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com