Method and system for recovering calcium and aluminum from aluminum industry sludge

A technology of aluminum industry and sludge, applied in chemical instruments and methods, sludge treatment, separation methods, etc., can solve problems such as insufficient fineness, low recovery rate, and reduced utilization value of aluminum-containing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

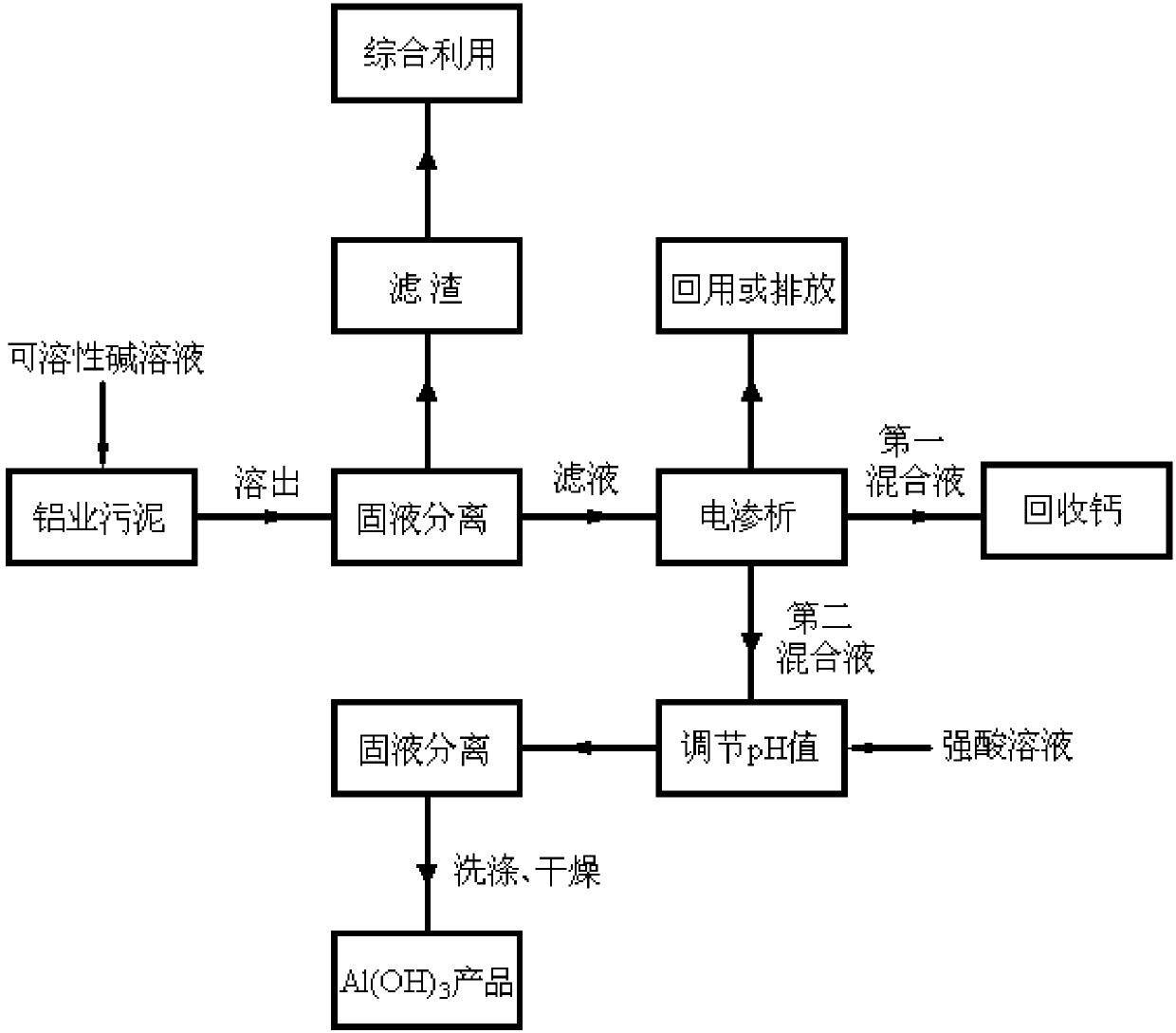

[0063] Such as figure 1 Shown, the method for reclaiming calcium and aluminum from aluminum industry sludge of the present embodiment, comprises the steps:

[0064] 1. Dissolution

[0065] Crush the aluminum industry sludge until it becomes fluffy. If there is solid sludge with large hardness in the aluminum industry sludge, use a crusher to crush it.

[0066] Get 10kg of crushed aluminum industry sludge, add 20L of 2mol / L sodium hydroxide solution, and make the sodium hydroxide solution immerse the aluminum industry sludge; then, dissolve 30min at room temperature and a stirring speed of 180r / min to obtain Dissolution of calcium and aluminum.

[0067] 2. Solid-liquid separation

[0068] A polypropylene plate-and-frame filter press is used to press-filter the above-mentioned stripping liquid. The pore size of the filter medium of the polypropylene plate-and-frame filter press is 600 mesh, and the filtrate and filter residue are collected respectively; wherein, the filtrate ...

Embodiment 2

[0078] The method for reclaiming calcium and aluminum from aluminum industry sludge of the present embodiment comprises the steps:

[0079] 1. Dissolution

[0080] Crush the aluminum industry sludge until it becomes fluffy. If there is solid sludge with large hardness in the aluminum industry sludge, use a crusher to crush it.

[0081] Get 10kg of crushed aluminum industry sludge, add 20L of 3mol / L sodium hydroxide solution, and make the sodium hydroxide solution immerse the aluminum industry sludge; subsequently, dissolve 30min at room temperature and a stirring speed of 200r / min to obtain Dissolution of calcium and aluminum.

[0082] 2. Solid-liquid separation

[0083] A polypropylene plate and frame filter press is used to press filter the above dissolution liquid. The pore size of the filter medium of the polypropylene plate and frame filter press is 700 mesh, and the filtrate and filter residue are collected respectively; wherein, the filtrate is used for subsequent ele...

Embodiment 3

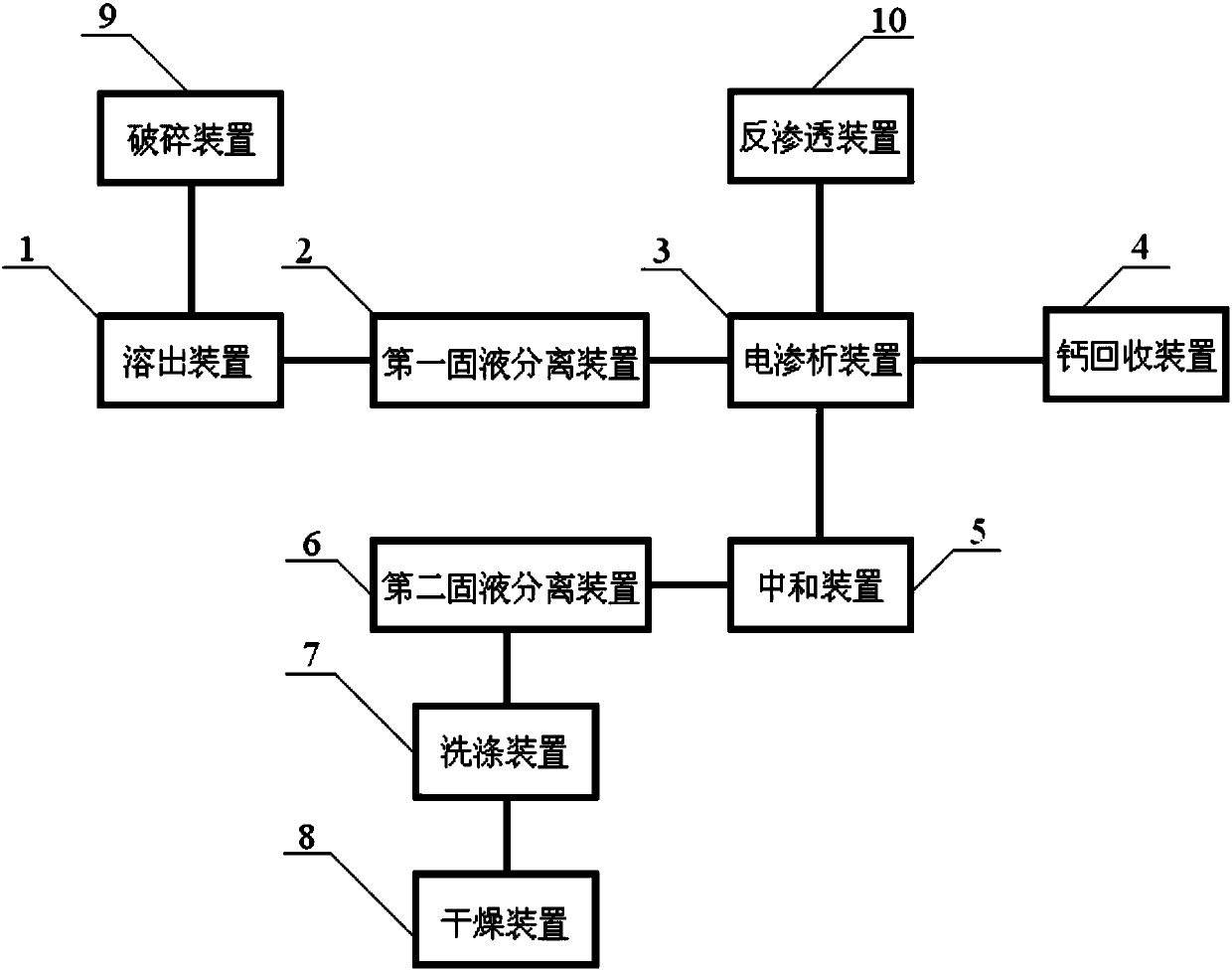

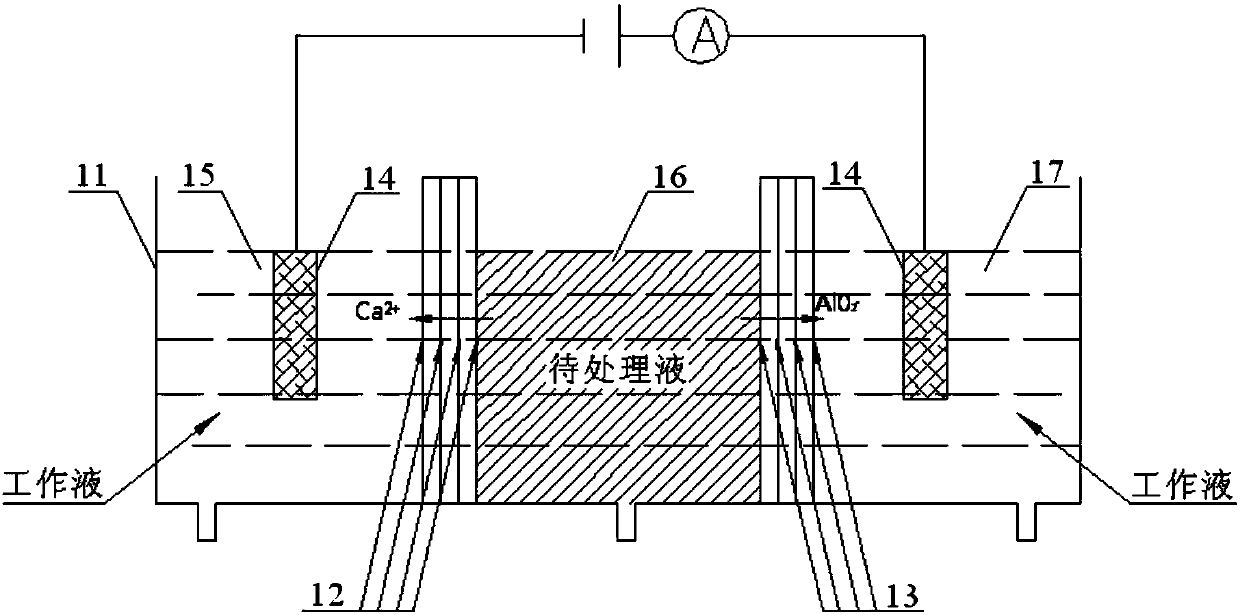

[0093] Such as figure 2 and Figure 4 As shown, the system for reclaiming calcium and aluminum from aluminum industry sludge of the present invention includes a dissolution device 1, which has an aluminum industry sludge inlet and an eluate outlet; the first solid-liquid separation device 2, which has an eluate inlet, Filtrate outlet and filter residue outlet, stripping liquid inlet is communicated with the stripping liquid outlet of stripping device 1; Electrodialysis device 3, it comprises cation exchange membrane 12 and anion exchange membrane 13 and has import, first outlet, second outlet and the 3rd outlet , the inlet is communicated with the filtrate outlet of the first solid-liquid separation device 2; the calcium recovery device 4 is connected with the first outlet of the electrodialysis device 3; the aluminum recovery device includes a neutralization device 5, a second solid-liquid The separation device 6 , the washing device 7 and the drying device 8 , and the neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com