A kind of phosphate type polycarboxylate water reducer and preparation method

A phosphate-type polycarboxylic acid and water reducing agent technology, which is applied in the field of building materials, can solve the problems of poor adaptability of aggregates with high mud content, and achieve the goals of improving adaptability, reducing adsorption, improving dispersion and dispersion retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

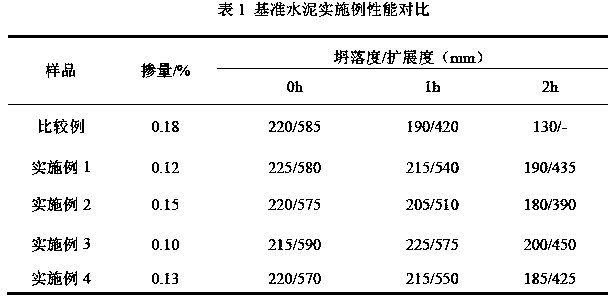

Examples

Embodiment 1

[0037] A preparation method of a phosphate-type polycarboxylate water reducer is provided in this embodiment, including:

[0038] (1) Preparation of the first polymer: Add 100.0g of polyacrylic acid with a mass fraction of 55% into the reaction vessel and heat to 50~70°C. Under the protection of nitrogen, add 300.0g of polyethylene glycol phosphate, 1.12g Antioxidant (specifically Irganox5057) and 2.30g catalyst (specifically ethylsulfonic acid), then, the temperature was raised to 155~160°C for esterification reaction under reduced pressure, the pressure dropped to 80mbar, and the reaction was kept for 4h, during which Remove water by vacuuming. After the reaction, cool the product to 60~80℃, add distilled water to dilute, and adjust the mass concentration of the polymer to 45~55%.

[0039] (2) Preparation of the second polymer: Add 340.0g of isobutylene alcohol polyoxyethylene ether with a molecular weight of 4000, 10.0g of hydroxybutyl methacrylate, 21.0g of acrylic acid, 3...

Embodiment 2

[0043] (1) Preparation of the first polymer: Add 130.0g of polyacrylic acid with a mass fraction of 55% into the reaction vessel and heat it to 50~70°C. Under the protection of nitrogen, add 350.0g of polyethylene glycol phosphate, 2.40g Irganox 5057 antioxidant and 3.67g of benzenesulfonic acid, then, the temperature was raised to 150~155°C, and the esterification reaction was carried out under reduced pressure, and the pressure was dropped to 80mbar, and the reaction was kept for 5 hours. Finally, cool the product to 60~80℃, add distilled water to dilute, and adjust the mass concentration of the polymer to 45~55%.

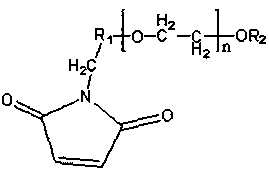

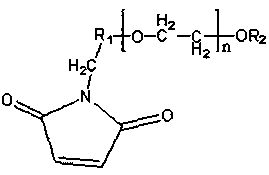

[0044] (2) Preparation of the second polymer: 40.0 g of methallyl alcohol polyoxyethylene ether with a molecular weight of 4000, 360.0 g of isobutyl alcohol polyoxyethylene ether with a molecular weight of 6000, and 5.0 g of hydroxybutyl methacrylate , 40.0g maleic anhydride, 50.0g compound A (R 1 for -CH 2 CH 2 , R 2 for CH 3 , n is 50) and 200.0g of deioni...

Embodiment 3

[0047] (1) Preparation of the first polymer: Add 115.0g of polyacrylic acid with a mass fraction of 55% into the reaction vessel and heat it to 50~70°C. Under nitrogen protection, add 342.0g of polyethylene glycol phosphate, 2.67g Irganox 5057 antioxidant and 4.88g of p-toluenesulfonic acid, then, the temperature was raised to 155~160°C for esterification under reduced pressure, the pressure dropped to 80mbar, and the heat preservation reaction was carried out for 3 hours. After the end, cool the product to 60~80°C, add distilled water to dilute, and adjust the mass concentration of the polymer to 45~55%.

[0048] (2) Preparation of the second polymer: 100.0 g of prenol polyoxyethylene ether with a molecular weight of 6000, 300.0 g of isobutenol polyoxyethylene ether with a molecular weight of 6000, 18.0 g of hydroxybutyl acrylate, 12.0 g Itaconic acid, 30.0g compound A (R1 is -CH 2 , R 2 for CH 3 , n is 40) and 200.0g deionized water were added to the reaction vessel and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com