Production method of high-purity 1,4-butanediol

A production method and technology of butanediol, which are applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as environmental pollution, poor selectivity, and increase production costs, and achieve a wide range of technology and product application prospects. The effect of reducing the content of impurities and suppressing catalytic side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

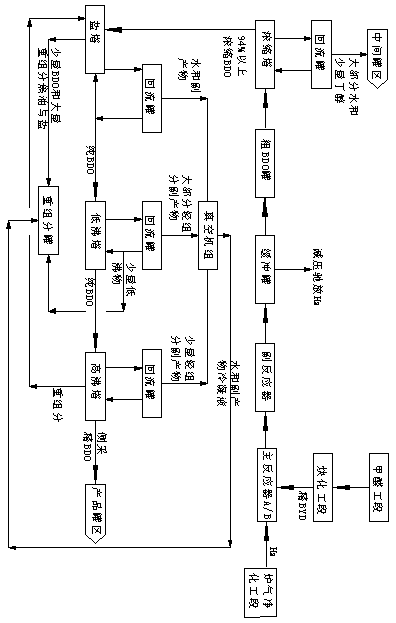

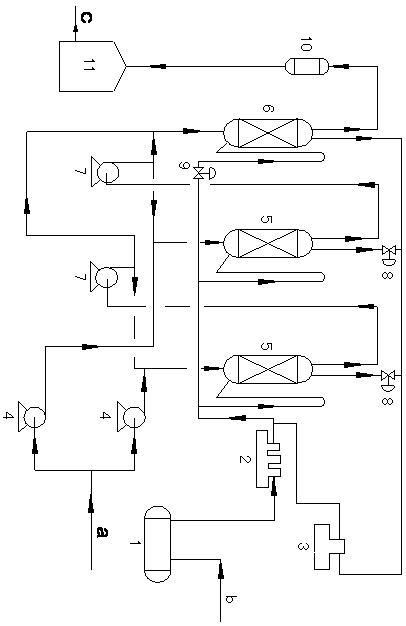

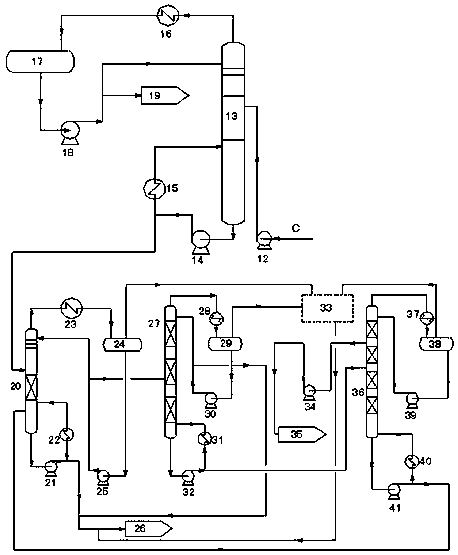

[0033] Refer to attached Figure 1-3 , the technical solution adopted by the present invention to solve the technical problem is: a production method of high-purity 1,4-butanediol, the production process mainly includes a formaldehyde section, an acetylenization section, a hydrogenation section and a product rectification section, The formaldehyde section is mainly raw material methanol and air to generate formaldehyde under the action of a catalyst; the acetylene chemical section is mainly to react acetylene and formaldehyde under the action of a catalyst to produce refined 1,4-butynediol; the hydrogenation section is mainly to Under pressure, 1,4-butynediol and hydrogen from the upstream furnace gas purification section (b) are produced under the action of a catalyst to produce crude 1,4-butanediol; the product rectification section is mainly for 1,4-butanediol Perform rectification treatment to obtain high-purity 1,4-butanediol product.

[0034] The difference of another e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com