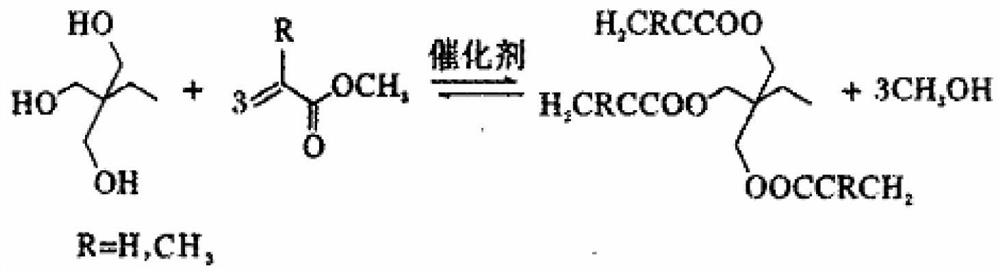

A method for synthesizing trimethylolpropane trimethacrylate and trimethylolpropane triacrylate by transesterification

A technology of trimethylolpropane trimethacrylate and trimethylolpropane triacrylate, which is applied in the reaction preparation of ester group and hydroxyl group, organic chemistry and other directions, can solve the problems of easy polymerization of raw materials and products, complicated processing technology, Solvent recovery is difficult and other problems, to achieve the effect of convenient product quality control, simple treatment process and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The synthesis process of trimethylolpropane trimethacrylate (TMPTMA):

[0034] Add respectively 100g of trimethylolpropane, 350g of methyl methacrylate, 2g of polymerization inhibitor TEMPO and 6g of hydroquinone, calcium oxide, potassium carbonate and chloride Lithium mixture 5g, heating and stirring, continue to feed air into the reactor, gradually warming up to the generation of reflux, the control reflux ratio is 2. As the reaction proceeds, the generated methanol and methyl methacrylate are discharged from the top of the fractionating column in the form of azeotrope. After a period of reaction, samples are taken from the flask for liquid chromatography analysis. The detection conditions of liquid chromatography are: chromatographic column C18 , 4.6×250mm, 5μm; mobile phase methanol-water volume ratio 30:70; flow rate 1.0mL / min; column temperature: 30°C; detection wavelength 254nm, injection volume: 10μL. When the product content ≥ 95%, the reaction is complete. C...

Embodiment 2

[0036] The synthesis process of trimethylolpropane trimethacrylate (TMPTMA):

[0037] Add trimethylolpropane 100g, methyl methacrylate 350g, polymerization inhibitor TEMPO 2g and p-hydroxyanisole 6g respectively in the reaction flask that thorn-shaped fractionating column and reflux device are housed, the catalyst that reclaims among the embodiment 1 , heating and stirring, continuously feed air into the reactor, gradually raise the temperature until reflux occurs, and control the reflux ratio to 2. As the reaction proceeds, the generated methanol and methyl methacrylate are extracted from the top of the fractionating column in the form of azeotrope. After a period of reaction, samples are taken from the flask for liquid chromatography analysis. The detection conditions of liquid chromatography are: chromatographic column C18, 4.6×250mm, 5μm; mobile phase methanol-water volume ratio: 30:70; flow rate: 1.0mL / min; column temperature: 30°C; detection wavelength: 254nm, injection ...

Embodiment 3

[0039] The synthesis process of trimethylolpropane triacrylate (TMPTA):

[0040]Add trimethylolpropane 100g, acrylate 300g, polymerization inhibitor 7052g and p-hydroxyanisole 6g, mixture 7g of salt of wormwood and lithium chloride in the reaction flask that thorn-shaped fractionating column and reflux device are housed respectively, heat Stir, continuously feed air into the reactor, gradually heat up until reflux occurs, and control the reflux ratio to 1.5. As the reaction proceeds, the generated methanol and methyl acrylate are extracted from the top of the fractionating column in the form of azeotropes. After a period of reaction, samples are taken from the flask for liquid chromatography analysis. The liquid chromatography detection conditions are: chromatographic column C18, 4.6×250mm, 5μm; mobile phase methanol-water volume ratio: 30:70; flow rate: 1.0mL / min; column temperature: 30°C; detection wavelength: 254nm, injection volume: 10μL. When the product content ≥ 95%, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com