Light-weight broadband multilayer structural wave-absorbing composite material and preparation method thereof

A multi-layer structure and composite material technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as poor mechanical strength, difficulty in controlling the distribution uniformity of wave-absorbing particles, and insufficient absorption frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

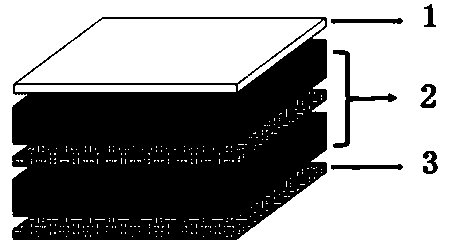

Image

Examples

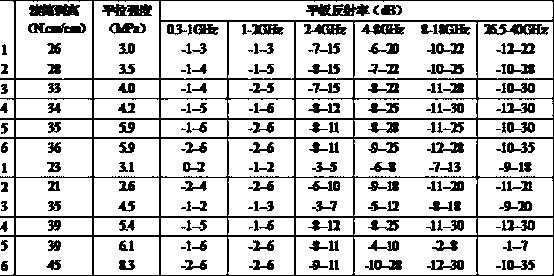

Embodiment 1

[0037] The wave absorbing agent superconducting carbon black (ECPEC600JD) 40%, lanthanum tin doped wave absorbing agent surface treatment agent 1.3%, dispersant sodium dodecylbenzene sulfonate 5%, polymer bismaleimide resin 36% %, added to the three-roll mill to disperse and then mixed in the high-speed mixer, after fully mixed, evenly coated on the surface density of 100g / m 2 24% surface of glass fiber cloth, as the surface material.

[0038] Coat the polymer uniformly to 50% of the mass at 2-18GHz, the dielectric constant is 2.0-5, the dielectric loss is 0.1-0.3, and the density is 75kg / m 3 The wave-absorbing PMI foam material and the wave-absorbing adhesive film electric loss body resistor sheet have a square resistance of 35Ω / port and a mass of 20%.

[0039] Add 5% of the wave absorbing agent conductive carbon black, 2% of the lanthanum tin-doped wave absorbing agent surface treatment agent, 5% of the dispersant sodium dodecylbenzene sulfonate, and 25% of the polymer epox...

Embodiment 2

[0043] Add 40% of conductive carbon black as wave absorbing agent, 1% of lanthanum tin-doped wave absorbing agent as surface treatment agent, 15% of lecithin as dispersing agent, and 26% of polymer epoxy resin into a three-roll mill for dispersion and then pass through high-speed Mix in a mixer, after fully mixing, evenly coat on surface density of 100g / m 2 24% of the surface of the quartz fiber cloth, as the surface material.

[0044] Coat the polymer evenly to 50% of the mass at 2-18GHz, the dielectric constant is 2.0-5, the dielectric loss is 0.2-0.5, and the density is 75kg / m 3 The wave-absorbing PMI foam material and the wave-absorbing adhesive film electric loss body resistor sheet have a square resistance of 50Ω / port and a mass of 20%.

[0045] Add 5% of multi-walled carbon nanotubes as absorbing agent, 0.5% of lanthanum-tin-doped absorbing agent as surface treatment agent, 5% as lecithin as dispersing agent, and 37% as polymer epoxy resin. After mixing in a high-spee...

Embodiment 3

[0049] Add 35% single-walled carbon nanotube powder as absorbing agent, 0.8% surface treatment agent doped with lanthanum-tin absorbing agent, 15% polyethylene wax as dispersant, and 26% polymer cyanate resin to three-roll grinding After being dispersed in the machine, it is mixed in a high-speed mixer, and after being fully mixed, it is evenly coated on the surface with a surface density of 100g / m 2 24% surface of glass fiber cloth, as the surface material.

[0050] Coat the polymer evenly to 50% of the mass at 2-18GHz with a dielectric constant of 2.0-5, a dielectric loss of 0.2-0.5, and a density of 110kg / m 3 The wave-absorbing PMI foam material and the wave-absorbing adhesive film electric loss body resistor sheet have a square resistance of 90Ω / port and a mass of 20%.

[0051] The wave absorbing agent multi-walled carbon nanotubes is 8%, the lanthanum tin doped wave absorbing agent surface treatment agent is 1.8%, the dispersant polyethylene glycol and polyethylene glyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com