Preparation method of direct fermentation agent of high-yield acetoin and aromatized mohevea bacillus and application of direct fermentation agent in production of Shanxi mature vinegar

A technology of direct-throwing fermentation agent and Bacillus vegiturus, applied in the field of microorganisms, can solve the problems of less research on the development and application of Bacillus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Screening of high-yielding acetoin, polyphenols and aromatizing spores

[0019] (1) Screening of high-yielding acetoin spores: the wine mash samples from the alcoholic fermentation stage of Shanxi old mature vinegar and the vinegar fermented grains samples from the acetic acid fermentation stage were collected respectively, diluted and coated with MRS medium, and finally 50 strains of spores were isolated . The ability to produce acetoin was determined by Voges-Proskauer (V-P) reaction and spectrophotometry, and Bacillus 15 produced the highest acetoin at 45.63g / L; followed by Bacillus 297 (40.52g / L) and Bacillus 2030 (40.28g / L).

[0020] The preparation method of the above-mentioned MRS solid medium is: peptone 10g, beef extract 10g, yeast extract 5g, K 2 HPO 4 2g, sodium acetate 2g, triammonium citrate 2g, glucose 20g, Tween 80 1mL, MgSO 4 0.2g, MnSO 4 0.05g, 20g agar, 1000mL distilled water, adjust the pH to 6.2‒6.6, and sterilize at 121°C for 20min...

Embodiment 2

[0047] Example 2: Strain identification of high-yielding acetoin, polyphenols and Aromaspora 15

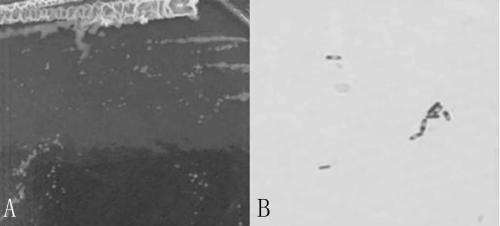

[0048] Morphological identification: Pick up 15 spores with an inoculation loop and streak on the MRS plate medium to isolate a single colony, take pictures of the colonies grown on the medium, record them, and then check by Gram staining microscope. Observe its cell morphology. Bacillus 15 formed a colony with a diameter of 4.80mm on the MRS plate medium, with irregular edges, rough surface and obvious wrinkles, translucent, dry, ridge-like protrusions in the middle, slightly viscous, and light yellow; its cell shape: leather Ran's staining was G + , rod-shaped, with spores in the middle, such as figure 1 shown.

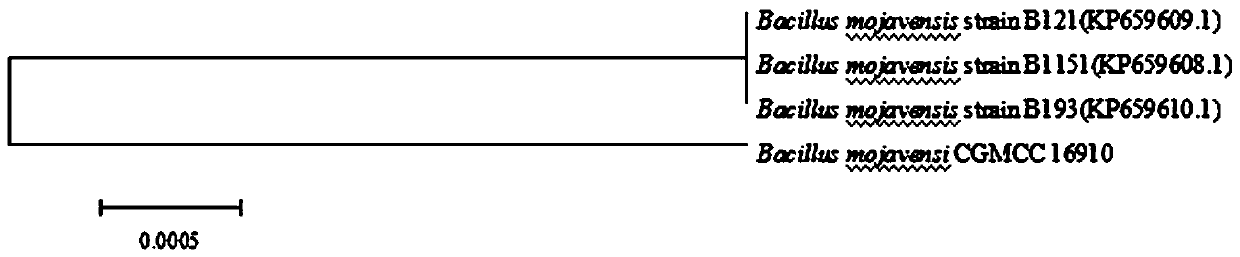

[0049] 16Sr DNA sequencing: the genome of Bacillus 15 was extracted with a kit, and the 16Sr DNA sequencing and strain identification were carried out. The primers were: upstream: 5′-CAGATGGGAGCTTGCTCCCTG-3′ downstream: 5′-CGACTTCACCCAATC

[0050] ATCTG-3′, using B...

Embodiment 3

[0051] Embodiment 3: the preparation of Bacillus mohewei CGMCC 16910 direct throw type starter

[0052] Insert the activated Bacillus mohewei CGMCC 16910 into the MRS medium at an inoculum amount of 3%, and cultivate it at 37°C and 180r / min for 24 hours, and the concentration of the bacteria at this time reaches 10 8 cfu / mL, use a hollow fiber membrane to concentrate the fermentation broth of Bacillus mohaiwei to 1 / 5 of the original volume, add a sterile protective agent to the concentrated fermentation broth, and the volume ratio of the concentrated fermentation broth to the protective agent is 1:3 (v: v) Mixing, processing the fermented liquid by low-temperature spray drying, and then vacuum-packing to obtain the Bacillus mohaiwi direct-throwing starter.

[0053] The preparation method of the above protective agent is: A: 10 g of skim milk powder, 100 mL of distilled water, sterilized at 115 °C for 15 min; B: 1.5 g of trehalose, 0.5 g of glycerin, 2 g of sorbitol, 1 g of mal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com