Preparation method of underwater super-oleophobic oil-water separation mesh membrane based on tannic acid modification

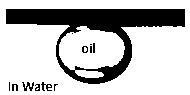

A technology of oil-water separation omentum and underwater super-oleophobic, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of unsuitable for industrial production and application, high cost, cumbersome preparation process, etc., to achieve the best choice Sexual penetration, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

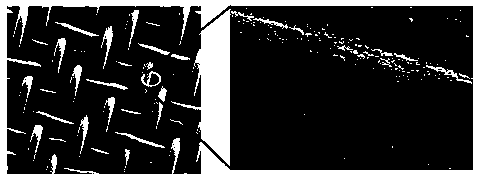

[0029] (1) Clean the 400-mesh stainless steel mesh and dry it for later use.

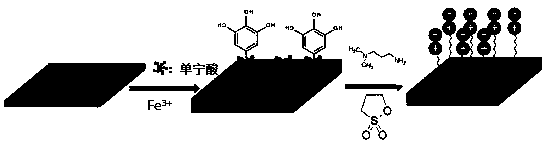

[0030] (2) Dissolving tannic acid in water, adjusting the pH to 8.3 to obtain a tannic acid solution with a mass percentage of tannic acid of 3%; dissolving ferric chloride in water to obtain a mass percentage of iron ions It is a 1% iron ion solution; dissolving N,N-dimethyl-1,3-diaminopropane in water to obtain 5% by mass of N-dimethyl-1,3-diaminopropane tertiary amine modification solution; 1,3-propane sultone was dissolved in methanol to obtain a zwitterionic modification solution with a mass percentage of 1,3-propane sultone of 2%.

[0031] (3) Soak the dried stainless steel mesh in the tannic acid solution, soak for 10 seconds, take it out and dry it; then soak it in the iron ion solution, soak it for 5 seconds, take it out and dry it; repeat this process 6 times; After taking it out, dry it in a drying oven at 80°C for 6 hours to obtain a tannic acid modified fabric net;

[0032] (4) Soak t...

Embodiment 2

[0036] (1) Clean the 300-mesh stainless steel mesh and dry it for later use.

[0037] (2) Dissolving tannic acid in water, adjusting the pH to 8 to obtain a tannic acid solution with a mass percentage of tannic acid of 4%; dissolving ferric chloride in water to obtain a mass percentage of iron ions 0.5% iron ion solution; dissolving N,N-dimethyl-1,3-diaminopropane in ethanol to obtain N-dimethyl-1,3-diaminopropane with a mass percentage of 2 % tertiary amine modification solution; 1,3-propane sultone was dissolved in ethanol to obtain a zwitterionic modification solution with a mass percentage of 1,3-propane sultone of 2%.

[0038] (3) Soak the dried stainless steel mesh in the tannic acid solution, soak for 1 hour, take it out and dry it; then soak it in the iron ion solution, soak it for 20 seconds, take it out and dry it; repeat this process 4 times; After taking it out, dry it in a drying oven at 60°C for 6 hours to obtain a tannic acid modified fabric net;

[0039] (4) ...

Embodiment 3

[0042] (1) Clean the 100-mesh copper mesh and dry it for later use.

[0043] (2) Dissolving tannic acid in ethanol, adjusting the pH to 9.0 to obtain a tannic acid solution with a mass percentage of tannic acid of 0.1%; dissolving ferric chloride in ethanol to obtain a mass percentage of iron ions Iron ion solution with a content of 0.01%; Dissolve N,N-dimethyl-1,3-diaminopropane in ethanol to obtain the mass percentage of N-dimethyl-1,3-diaminopropane 0.01% tertiary amine modification solution; dissolving γ-butyrolactone in ethanol to obtain a zwitterion modification solution with a mass percentage of γ-butyrolactone of 0.01%.

[0044] (3) Soak the dried copper mesh in the tannic acid solution, soak for 30 seconds, take it out and dry it; then soak it in the iron ion solution, soak it for 30 seconds, take it out and dry it; repeat this process 15 times; After taking it out, dry it in a drying oven at 50°C for 0.5 hour to obtain a tannic acid modified fabric net;

[0045] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com