Preparation method of a soft magnetic powder core with μ = 150-250

A magnetic powder core, sendust technology, applied in the field of preparation of high magnetic permeability μ = 150-250 sendust magnetic powder core, can solve the problem of low magnetic permeability of magnetic powder core, achieve low power loss, improve heat treatment Effect of Temperature, High DC Superposition Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

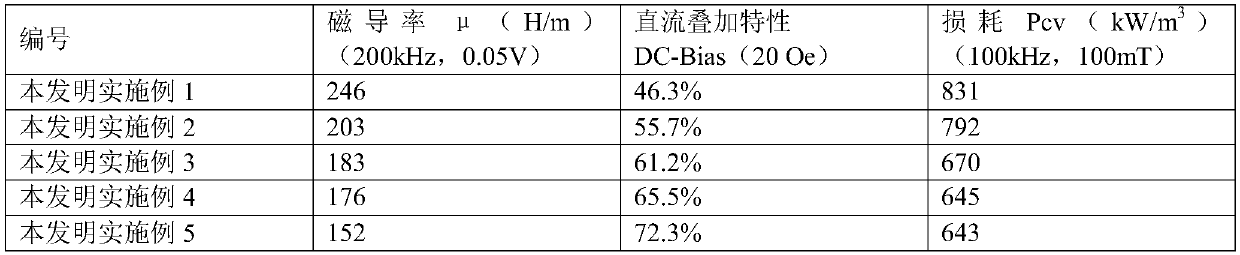

Embodiment 1

[0028] A method for preparing a soft magnetic powder core of sendust with μ=150-250, taking sendust magnetic powder, C: 0.008%, N: 0.01%, O: 0.08%, Si: 9.5%, Al: 5.5%, I The amount is iron, the powder particle size D99=158um, D50=68um, the original powder is annealed at 800°C for 6 hours in a pure nitrogen atmosphere; then add 0.012% phosphoric acid aqueous solution and fry until completely dry; then add 0.1% magnesium hydroxide and 0.1% sodium silicate Mix the aqueous solution and fry until completely dry; add 0.3% high-temperature organic silica gel water acetone solution, dry until completely dry, and finally add 0.3% of the weight of magnetic powder zinc stearate as a release agent, mix well, and press to 20.3mm* 12.7mm*6.35mm magnetic ring, the molding pressure is 18.5t / cm2; the molded magnetic core is heat-treated at 700°C for 50 minutes in a nitrogen atmosphere; after cooling, epoxy resin is sprayed on the surface of the magnetic core, and after curing, μ =246 sendust m...

Embodiment 2

[0030] A method for preparing a soft magnetic powder core of sendust with μ=150-250, taking sendust magnetic powder, C: 0.012%, N: 0.05%, O: 0.2%, Si: 9.0%, Al: 5.1%, and The amount is iron, the powder particle size D99=147um, D50=60um, the original powder is annealed at 700°C for 0.5h in a pure hydrogen atmosphere; then add 0.1% phosphoric acid alcohol solution and fry until completely dry; then add 0.3% kaolin and 0.2% Mica powder mixed aqueous solution, fry until completely dry; add mass fraction of 0.5% high-temperature organic silica gel aqueous toluene solution, dry until completely dry, finally add 0.5% of the weight of magnetic powder aluminum stearate as a release agent, after mixing evenly, Press it into a magnetic ring of 20.3mm*12.7mm*6.35mm, and the molding pressure is 20.5t / cm2; heat-treat the molded magnetic core at 850°C for 30 minutes in a nitrogen atmosphere; spray epoxy resin on the surface of the magnetic core after cooling , After solidification, μ=203 sen...

Embodiment 3

[0032] A method for preparing a soft magnetic powder core of sendust with μ=150-250, taking sendust magnetic powder, C: 0.03%, N: 0.2%, O: 0.05%, Si: 7.5%, A1: 8.5%, and The amount is iron, powder particle size D99=145um, D50=63um, the original powder is annealed at 900°C for 0.5h in a pure argon atmosphere; then add 0.5% phosphate acetone solution and fry until completely dry; then add 0.2% aluminum hydroxide by mass fraction , 0.2% potassium silicate mixed aqueous solution, fry until completely dry; add 0.8% mass fraction of high-temperature organic silica gel water acetone solution, dry until completely dry, and finally add 0.1% molybdenum disulfide by weight of the magnetic powder as a release agent, mix After uniformity, press it into a magnetic ring of 20.3mm*12.7mm*6.35mm, and the molding pressure is 16t / cm2; heat-treat the molded magnetic core at 600°C for 120min in an argon atmosphere; spray on the surface of the magnetic core after cooling Epoxy resin, after curing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com