Preparation method of fluorphlogopite mica, and application of fluorphlogopite mica in preparation of two-dimensional crystals

A technology of fluorocrystalline mica and sodium fluoride, applied in the material field, can solve the problems of poor flatness, poor stability of fluorocrystalline mica, very high requirements on transparency and flatness, and achieves the effect of high cost and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

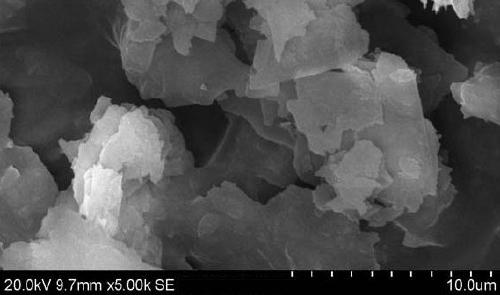

[0045] The present embodiment provides a kind of preparation method of fluorphlogopite, comprises the steps:

[0046] Step 1, mixing 50.5g of magnesite, 28.2g of montmorillonite and 18.02g of quartz sand through a high-speed mechanical impact mill and pulverizing into a mixture of millimeter-scale fine sand particles, the particle size of which is 0.01-1mm;

[0047] Step 2, adding 200 mL of 1mol / L nitric acid solution to the fine sand mixture to react to obtain a suspension;

[0048] Step 3, add the sodium fluoride of 16.8g and the potassium chloride of 14.9g stirring reaction in the suspension liquid, then adjust the pH value of the solution by the sodium hydroxide solution of 0.5mol / L to be neutral, centrifuge to obtain the precipitate, the The precipitate was calcined in a muffle furnace at 550°C for 5 hours, then kept for 12 hours, and then gradually cooled to room temperature at a cooling rate of 1°C / min to obtain the crude fluorophlogopite;

[0049] Step 4, the crude fl...

Embodiment 2

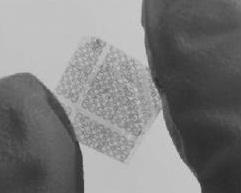

[0052] This implementation provides the application of the fluorophlogopite prepared in Example 1 above in the preparation of two-dimensional crystals. This application is specifically to provide the fluorphlogopite prepared in Example 1 for the preparation of Bi 2 o 2 Se two-dimensional crystal thin film material, comprises the steps:

[0053] Step 1: Perform plasma etching on the fluorophlogopite mica prepared in Example 1 to obtain a patterned fluorophlogopite matrix. The plasma etching power is 100 W, and the etching time is 15 minutes.

[0054] Step 2, deposit Bi on the fluorophlogopite substrate by pulsed laser deposition (deposition temperature is 550°C, deposition time is 10min) 2 o 2 Se thus prepares Bi 2 o 2 Se two-dimensional crystal thin film material. After testing, the Bi 2 o 2 The mobility of Se two-dimensional crystal thin film material is as high as 1800 cm 2 V -1 the s -1 ; Photoelectric responsivity up to 2000 AW at 550nm -1 .

[0055] The pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com