Zinc oxide film and preparation method thereof, and luminescent device

A technology of zinc oxide film and zinc oxide, which is applied in the direction of semiconductor devices, electrical components, liquid chemical plating, etc., can solve the problems of reducing electron transport performance, reducing electron-hole pair radiation combination, surface oxygen defects, etc. Transmission performance, realization of large area and mass production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

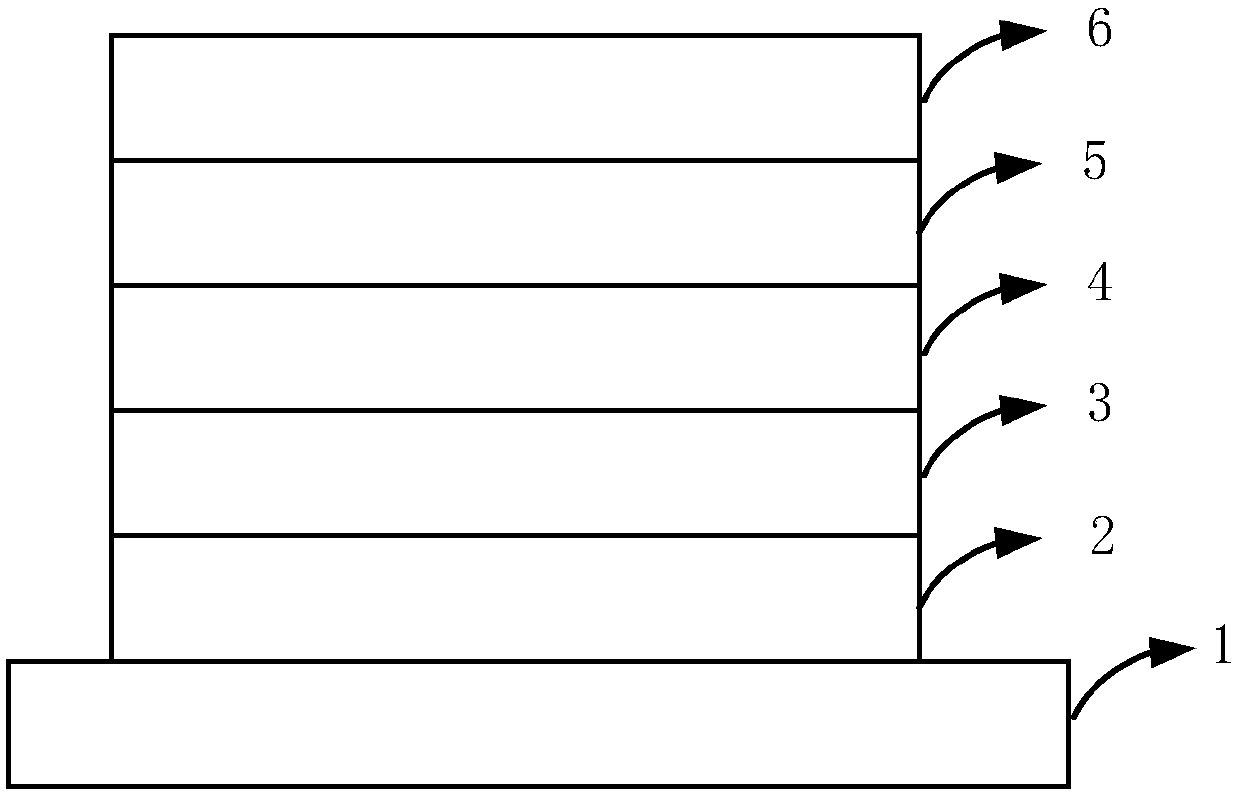

Image

Examples

preparation example Construction

[0014] Embodiments of the present invention provide a method for preparing a zinc oxide film. The preparation method comprises the following steps:

[0015] Step S11 : providing a zinc precursor salt solution, mixing and adding a complexing agent, mixing and adding a peroxide to form a mixed reaction system, and reacting to obtain a zinc oxide crystal grain solution.

[0016] In the embodiment of the present invention, the zinc precursor salt solution is hydrolyzed at 25°C to 40°C in the presence of a complexing agent to form zinc hydroxide, and zinc hydroxide is polycondensed to form zinc oxide particles. The reaction rate is very fast. It is necessary to quickly add peroxide after mixing and adding a complexing agent to form a mixed reaction system of peroxide. During the reaction process, the peroxide can rapidly oxidize the zinc ions in the zinc precursor salt solution to form zinc peroxide ZnO 2 , ZnO 2 It is easily decomposed into small ZnO particles, and ZnO particles...

Embodiment 1

[0027] Embodiment 1: The following takes the use of zinc acetate, ethanol, ethanolamine, and hydrogen peroxide as examples to introduce in detail.

[0028] Zinc acetate was dissolved in 50ml of ethanol solution to form a concentration of 0.2mol / L-1mol / L. After fully stirring, the constant temperature was controlled at 40°C, and an appropriate amount of ethanolamine was added dropwise (the molar ratio of ethanolamine to zinc was 1.8-2.5:1). Then, keep w(H in the system 2 O 2 )=0.2%-1% add H 2 O 2 Mass fraction of 30% H 2 O 2 solution, ammonia water to adjust the pH value (6<pH<9), keep stirring for 2h-4h to form a precursor solution. The precursor solution was dropped onto an ITO substrate, spin-coated and annealed at 250°C to 350°C to form a film.

Embodiment 2

[0029] Embodiment 2: The following takes zinc nitrate, isopropanol, diethanolamine, and sodium peroxide as examples to introduce in detail.

[0030] Zinc nitrate was dissolved in 50ml of isopropanol solution to form a concentration of 0.2mol / L-1mol / L, after fully stirring, the constant temperature was controlled at 40°C, and an appropriate amount of diethanolamine (the molar ratio of diethanolamine and zinc was 2) was added dropwise. :1). Then, keep w(Na in the system 2 O 2 )=0.2%-1% add Na 2 O 2 , dilute nitric acid to adjust the pH value (6<pH<9), keep stirring for 2h-4h to form a precursor solution. The precursor solution was dropped onto an ITO substrate, spin-coated and annealed at 250°C to 350°C to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com