Composite material, preparation method and application thereof, light-emitting diode and preparation method of light-emitting diode

A composite material, cerium oxide technology, applied in the field of nanomaterials, can solve problems such as instability, surface defects of cerium oxide nanoparticles, etc., achieve good stability, good electron transport performance, and improve the effect of electron transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

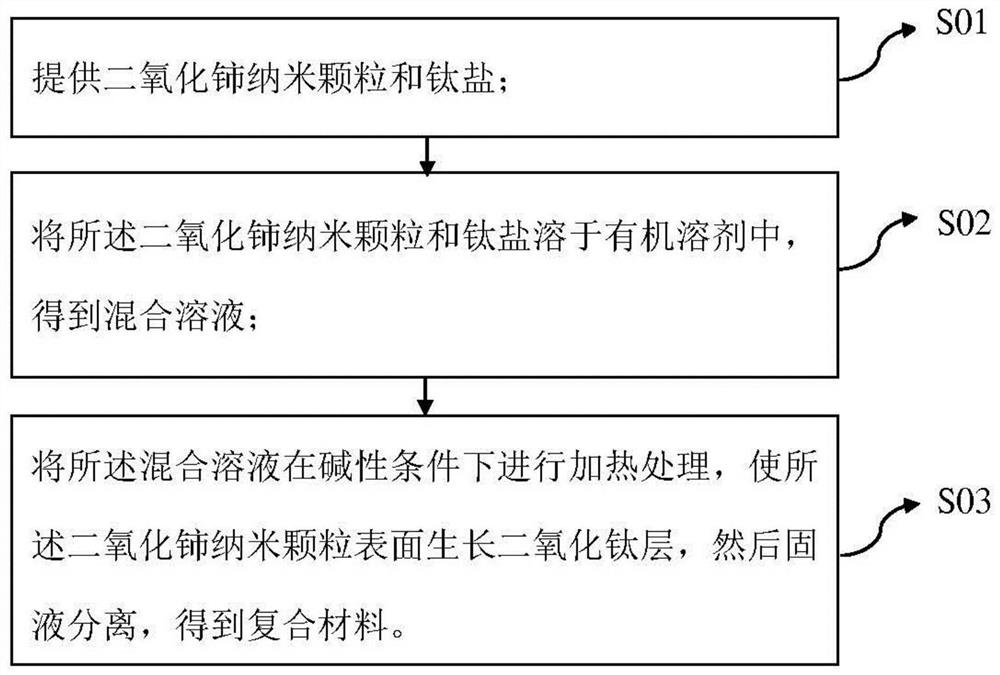

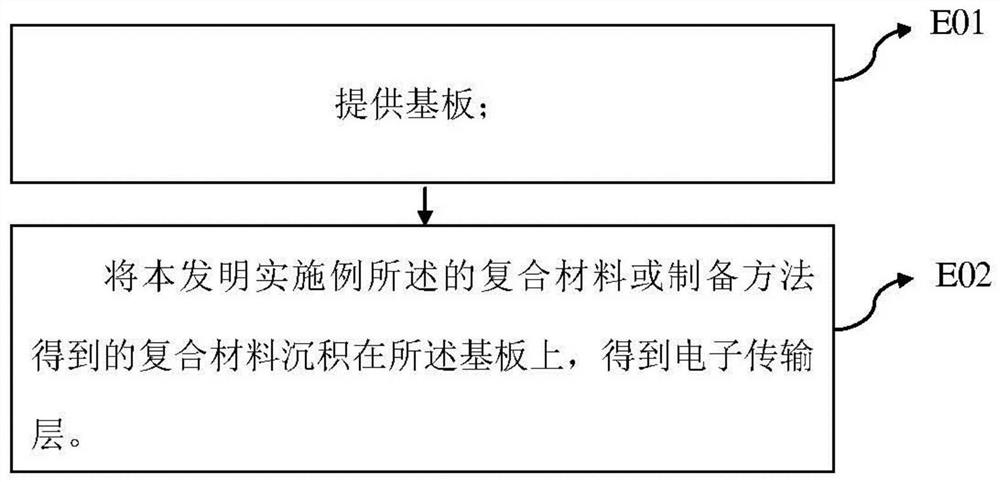

[0026] On the one hand, the embodiment of the present invention provides a kind of preparation method of composite material, such as figure 1 Shown, this preparation method comprises the steps:

[0027] S01: Provide ceria nanoparticles and titanium salt;

[0028] S02: dissolving the ceria nanoparticles and titanium salt in an organic solvent to obtain a mixed solution;

[0029] S03: heat-treating the mixed solution under alkaline conditions to grow a titanium dioxide layer on the surface of the ceria nanoparticles, and then separate solid and liquid to obtain a composite material.

[0030] In the preparation method of the composite material provided by the embodiment of the present invention, after dissolving the ceria nanoparticles and the titanium salt in an organic solvent, heating is carried out under alkaline conditions, so that a titanium dioxide layer can be coated on the surface of the ceria nanoparticles , and finally solid-liquid separation to obtain a composite ma...

Embodiment 1

[0084] The preparation of a composite film is introduced in detail by using cerium sulfate, ethanol, potassium hydroxide and titanium sulfate as raw materials.

[0085] 1) First, add an appropriate amount of cerium sulfate into 50ml of ethanol, stir and dissolve at 70°C to form a cerium sulfate solution with a total concentration of 0.5M; weigh potassium hydroxide, dissolve potassium hydroxide in 10ml of ethanol to obtain lye, This lye is added in the above-mentioned cerium sulfate solution (molar ratio, OH - : Ce 4+ =4:1, pH=12). Stirring was continued at 70 °C for 4 h to obtain a homogeneous solution. Subsequently, after the solution is cooled, it is precipitated with ethyl acetate, and after centrifugation, it is dissolved with a small amount of ethanol, and the precipitation and dissolution steps are repeated 3 times, and dried to obtain CeO 2 nanomaterials.

[0086] 2) the CeO 2 Nanoparticles and an appropriate amount of titanium sulfate were added to 30ml of ethanol...

Embodiment 2

[0089] The preparation of a composite film is introduced in detail by using cerium nitrate, methanol, ethanolamine and titanium nitrate as raw materials.

[0090] 1) First, an appropriate amount of cerium nitrate was added to 50 ml of methanol, stirred and dissolved at 60° C. to form a cerium nitrate solution with a total concentration of 0.8M. Take ethanolamine, then ethanolamine is dissolved in 10ml methanol to obtain lye, and the lye of alkali is added in the above-mentioned cerium nitrate solution (molar ratio, ethanolamine: Ce 4+ =4.5:1, pH=13). Stirring was continued at 60 °C for 4 h to obtain a homogeneous solution. Subsequently, after the solution is cooled, it is precipitated with heptane, and after centrifugation, it is dissolved with a small amount of methanol, and the precipitation and dissolution steps are repeated 3 times, and dried to obtain CeO 2 nanomaterials.

[0091] 2) the CeO 2 Nanoparticles and an appropriate amount of titanium nitrate were added to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com