Low-cost and high-rate graphene-based lithium iron phosphate electrode plate and preparation method thereof

An alkenyl lithium iron phosphate, high-rate technology, applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve the problem of slow electron conduction and lithium ion diffusion rate, limiting electrochemical performance of lithium iron phosphate batteries, particle Insufficient combination of substances and other issues, to achieve excellent cycle discharge rate performance, improve specific capacity and rate discharge performance, and reduce the effect of graphene agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

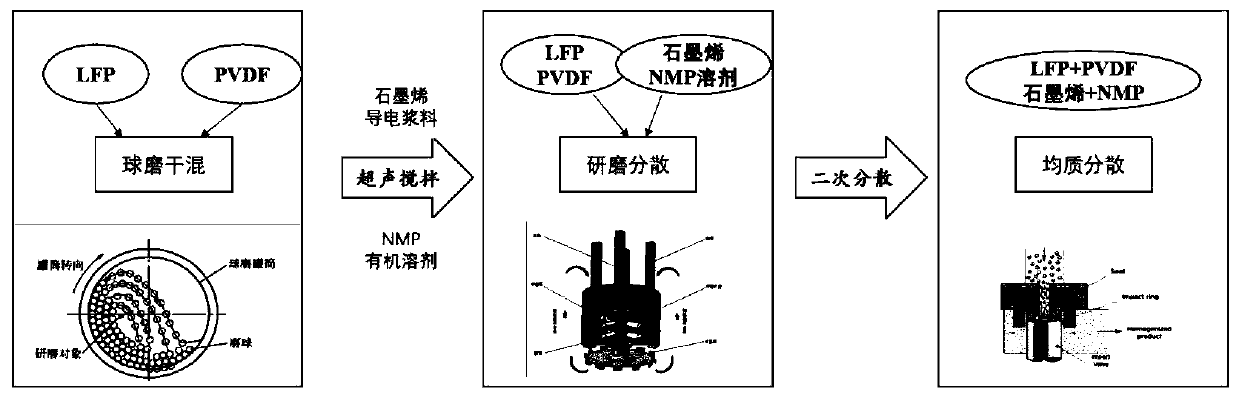

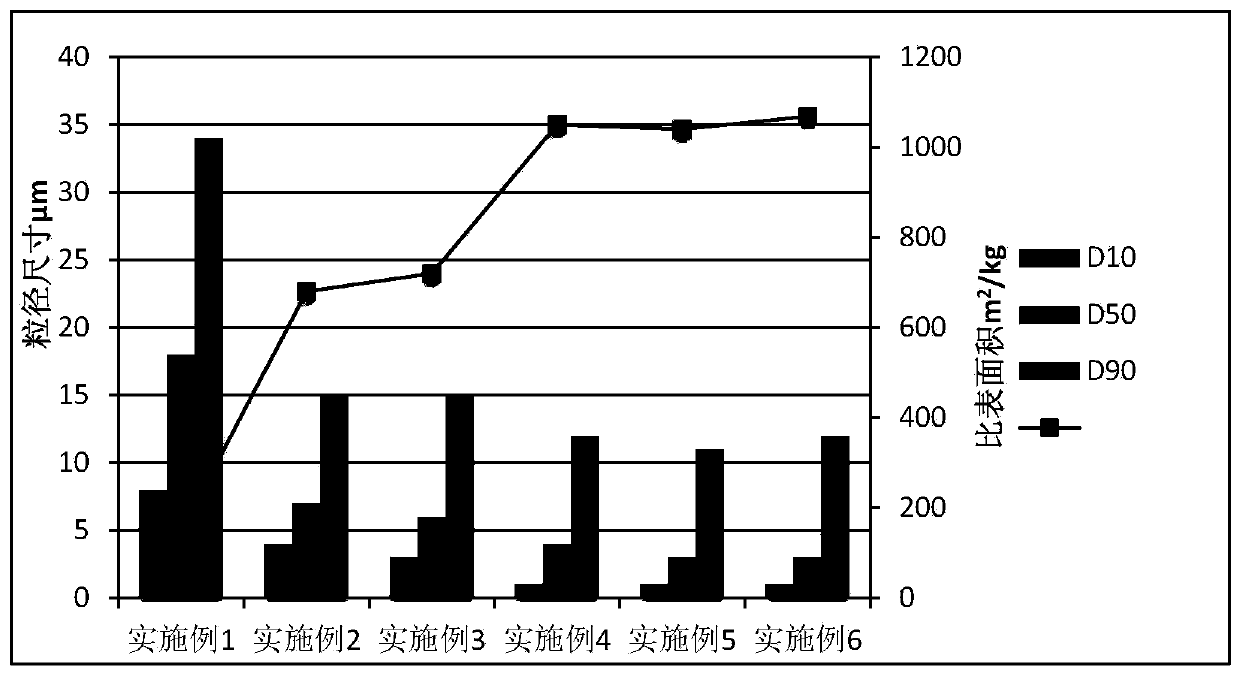

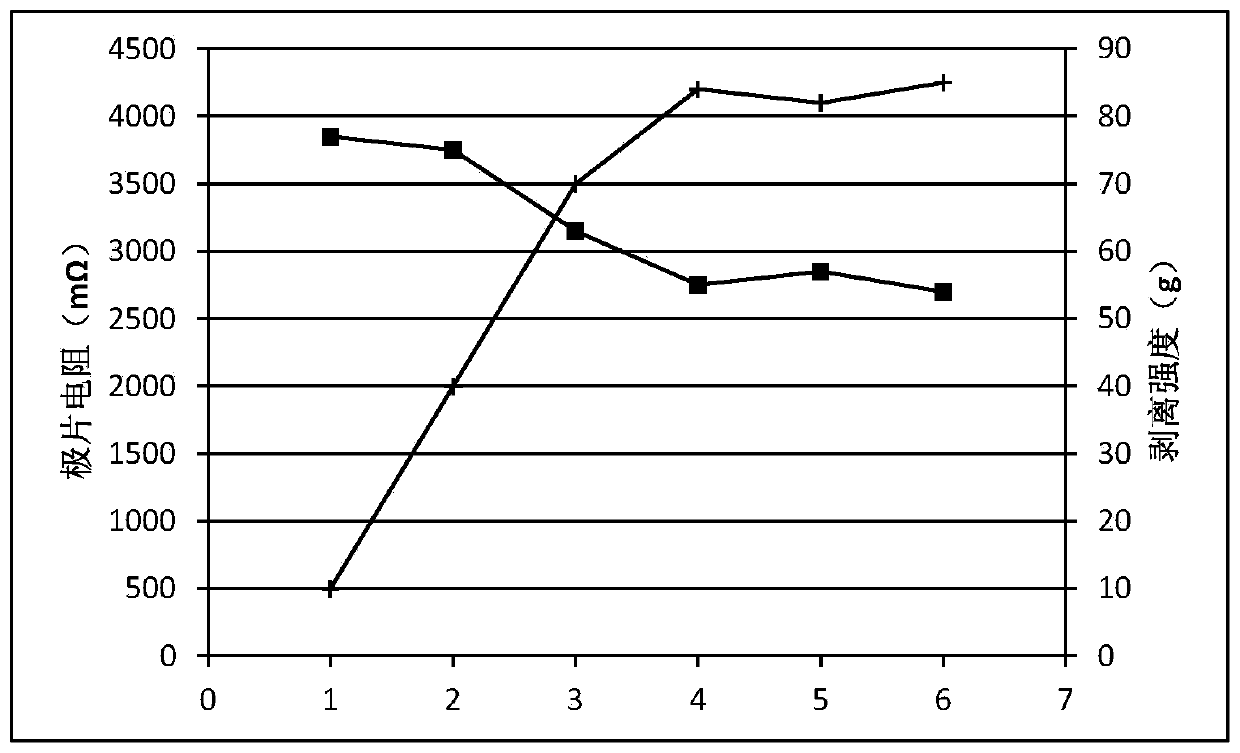

[0020] The preparation process of the graphene-based lithium iron phosphate pole piece is as follows: the positive electrode uses carbon-coated lithium iron phosphate as the active material, graphene as the conductive agent, PVDF as the binder, and the proportion of ingredients is LiFePO 4 :G:PVDF=94:3:3. LiFePO was first mixed with a ball mill 4 Dry mixing with PVDF powder, using zirconia ball milling beads for ball milling, the ball milling time is 3h, and the ball milling speed is 100rpm. Then the graphene conductive paste was added to the solvent for ultrasonic stirring, the amount of NMP added was the same as the quality of the graphene conductive paste, and the ultrasonic stirring time was 1 h. The pre-dry mixed powder was added to the graphene NMP solvent, and a double planetary mixer was used for high-speed dispersion, the stirring power was 1000W, and the stirring time was 2h. The prepared positive electrode slurry was coated on both sides of the carbon-coated alumi...

Embodiment 2

[0022] The preparation process of the graphene-based lithium iron phosphate pole piece is as follows: the positive pole piece uses carbon-coated lithium iron phosphate as the active material, graphene as the conductive agent, PVDF as the binder, and the proportion of ingredients is LiFePO 4 :G:PVDF=94:3:3. LiFePO was first mixed with a ball mill 4 Dry mixing with PVDF powder, using zirconia ball milling beads for ball milling, the ball milling time is 3h, and the ball milling speed is 100rpm. Then the graphene conductive paste was added to the solvent for ultrasonic stirring, the amount of NMP added was the same as the quality of the graphene conductive paste, and the ultrasonic stirring time was 1 h. The pre-dry mixed powder was added to the graphene NMP solvent, and high-speed dispersion was carried out by wet grinding, and the grinding and dispersing time was 2h. The prepared positive electrode slurry is coated on both sides and carbon-coated aluminum foil current collect...

Embodiment 3

[0024] The preparation process of the graphene-based lithium iron phosphate pole piece is as follows: the positive pole piece uses carbon-coated lithium iron phosphate as the active material, graphene as the conductive agent, PVDF as the binder, and the proportion of ingredients is LiFePO 4 :G:PVDF=94:3:3. LiFePO was first mixed with a ball mill 4 Dry mixing with PVDF powder, using zirconia ball milling beads for ball milling, the ball milling time is 3h, and the ball milling speed is 100rpm. Then the graphene conductive paste was added to the solvent for ultrasonic stirring, the amount of NMP added was the same as the quality of the graphene conductive paste, and the ultrasonic stirring time was 1 h. The pre-dry mixed powder was added to the graphene NMP solvent, and a high-speed homogenizer was used for high-speed dispersion. The valve pressure of the homogenizer was 400bar, the nozzle pressure was 500bar, and the dispersion time was 2h. The prepared positive electrode slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com