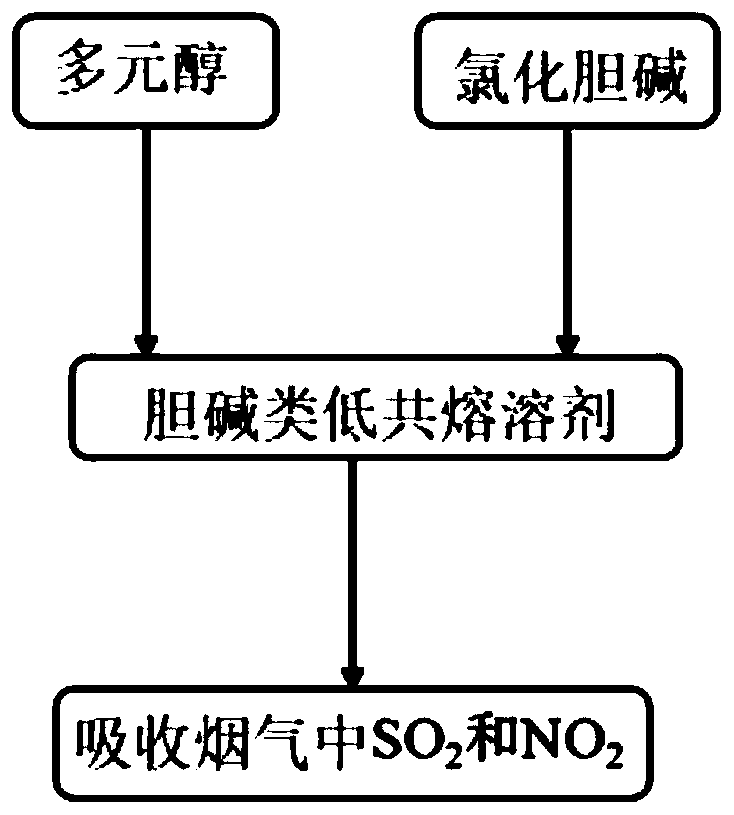

Polyol-choline eutectic solvent used to absorb SO2 and NO2 and preparation method thereof

A technology of deep eutectic solvents and polyols, applied in chemical instruments and methods, separation methods, dispersion particle separation, etc., to achieve the effects of mild synthesis conditions, mild conditions, low melting point and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

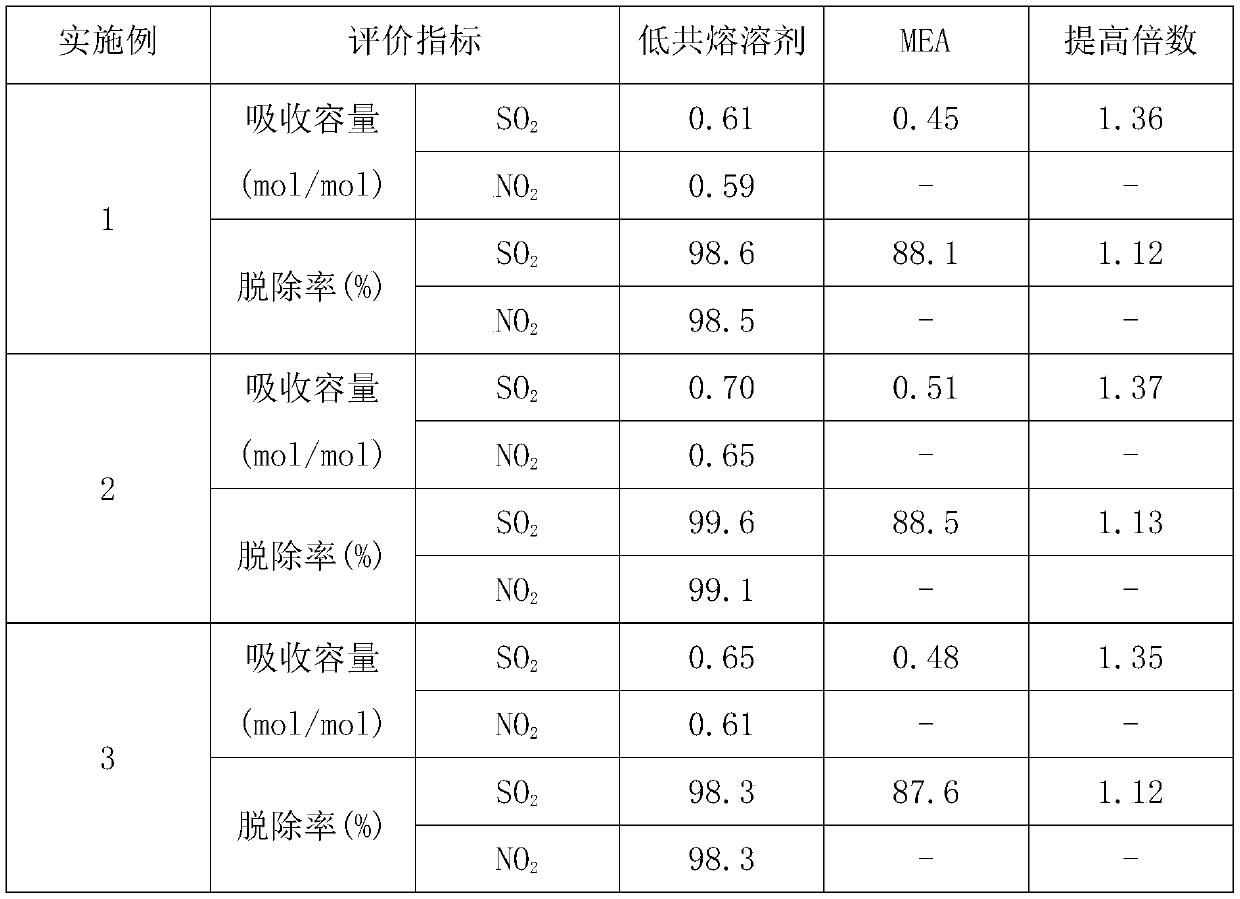

Embodiment 1

[0026] for absorbing SO 2 and NO 2 The polyol-choline deep eutectic solvent is composed of hydrogen bond donor ethanol and hydrogen bond acceptor choline chloride, and the molar ratio of ethanol and choline chloride is 4:1.

[0027] The preparation method of ethanol-choline chloride deep eutectic solvent, takes by weighing 46.07g (1mol) ethanol and 53.14g (0.25mol) choline chloride, gets a three-necked flask, adds weighed choline chloride and Ethanol, stirred, put into an ultrasonic device, the temperature of the water bath is controlled at 45±2°C for 0.5h-1h, mixed evenly to form a colorless uniform transparent liquid; after the reaction is completed, put it into a vacuum drying oven and dry at 80°C for 10h. Obtain ethanol-choline chloride deep eutectic solvent. The sample has a viscosity of 13.60 mPa·s at 30°C and a melting point of -27.39°C.

[0028] Take the ethanol-choline chloride deep eutectic solvent and place it in the bubble column reactor. The temperature of the ...

Embodiment 2

[0032] for absorbing SO 2 and NO 2 The polyol-choline deep eutectic solvent is composed of hydrogen bond donor ethylene glycol and hydrogen bond acceptor choline chloride, and the molar ratio of ethylene glycol to choline chloride is 4:1.

[0033] The preparation method of ethylene glycol-choline chloride deep eutectic solvent, takes by weighing 62.07 (1mol) ethylene glycol and 53.14g (0.25mol) choline chloride, gets three-necked flask, adds the choline chloride of weighing in flask Alkali and ethylene glycol, stir, the solution temperature is controlled at 45±2°C and kept for 0.5h, mix evenly to form a colorless transparent clear liquid; after the reaction is completed, put it in a vacuum drying oven and dry at 80°C for 10h to obtain ethylene glycol - Choline chloride deep eutectic solvent. The sample has a viscosity of 21.75 mPa·s at 30°C and a melting point of -107.76°C.

[0034] Take the ethylene glycol-choline chloride deep eutectic solvent and place it in the bubble c...

Embodiment 3

[0038] for absorbing SO 2 and NO 2 The polyol-choline deep eutectic solvent is composed of hydrogen bond donor glycerol and hydrogen bond acceptor choline chloride, and the molar ratio of glycerol and choline chloride is 4:1.

[0039] The preparation method of glycerol-choline chloride deep eutectic solvent, takes by weighing 92.09g (1mol) glycerol and 53.14g (0.25mol) choline chloride, gets three-necked flask, adds weighing to flask in flask Add weighed choline chloride and glycerin to the solution, stir, and keep the temperature of the solution at 45±2°C for 0.5h, mix evenly to form a colorless, transparent and clear liquid; after the reaction, put it into a vacuum drying oven at 80°C Drying at low temperature for 10h to obtain glycerol-choline chloride deep eutectic solvent. The viscosity of this sample at 30°C is 277.5 mPa·s, and the glass transition temperature is -107.30°C.

[0040] Take the glycerol-choline chloride deep eutectic solvent and place it in the bubble co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com