Tile antislipping agent, and preparation method thereof

An anti-slip agent, ceramic tile technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of surface gloss decline, environmental impact, loss of anti-slip effect, etc., to reduce gloss and increase friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] An anti-slip agent for tiles, which is compounded by component A and component B according to the volume ratio of 1:0.8, and the component A includes the following raw materials in parts by weight:

[0057]

[0058]

[0059] B component comprises the raw material of following weight portion:

[0060]

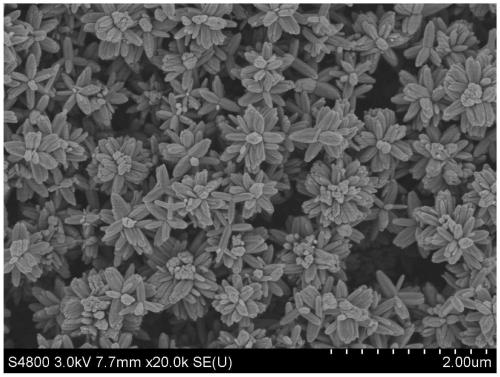

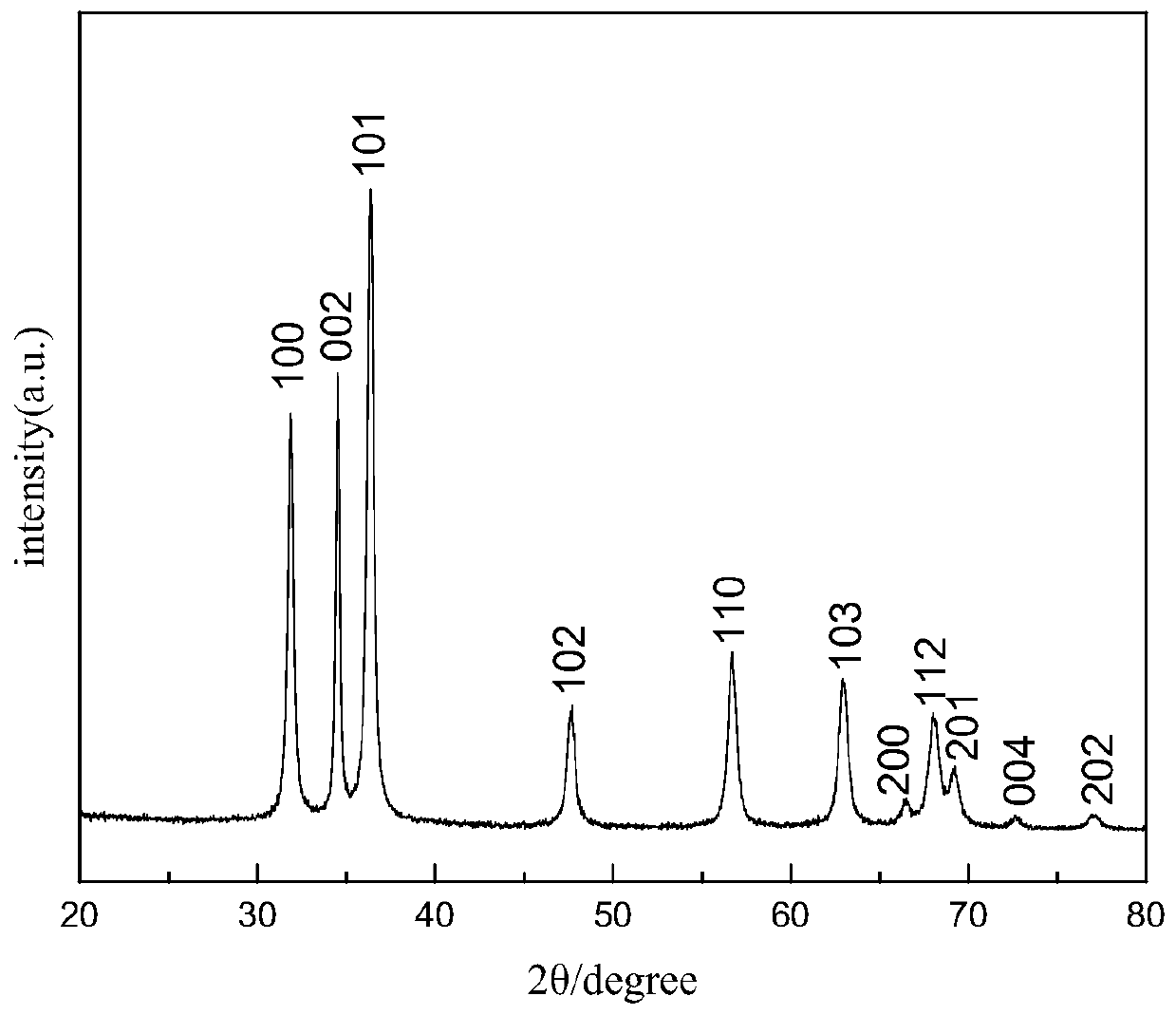

[0061] The nano zinc oxide is spiny nano zinc oxide.

[0062] The corrosion inhibitor is compounded from salts of weak acids and strong bases and salts of weak bases and strong salts in a molar ratio of 1:0.8.

[0063] The dispersion stabilizer is ethylene glycol ether.

[0064] The fluoride salt is ammonium fluoride.

[0065] The silicone oil is methyl silicone oil.

[0066] The humectant is butanediol.

[0067] The silane coupling agent is sodium methyl silicate.

[0068] The surfactant is sodium dodecylbenzenesulfonate.

[0069] The preparation method of the ceramic tile anti-slip agent, the A component and the B component are prepared separately and pac...

Embodiment 2

[0078] An anti-slip agent for tiles, which is compounded by component A and component B according to the volume ratio of 1:2.5, and the component A includes the following raw materials in parts by weight:

[0079]

[0080] B component comprises the raw material of following weight portion:

[0081]

[0082] The nano zinc oxide is spiny nano zinc oxide.

[0083] The corrosion inhibitor is compounded by weak acid and strong base salt and weak base and strong salt according to the molar ratio of 1:1.2.

[0084] The dispersion stabilizer is ethylene glycol butyl ether.

[0085] The fluoride salt is ammonium bifluoride.

[0086] The silicone oil is methyl hydroxy silicone oil.

[0087] Described humectant is propylene glycol.

[0088] The silane coupling agent is methyltrimethoxysilane.

[0089] The surfactant is sodium lauryl sulfate.

[0090] The preparation method of the ceramic tile anti-slip agent, the A component and the B component are prepared separately and pac...

Embodiment 3

[0099] An anti-slip agent for ceramic tiles, which is compounded by component A and component B according to the volume ratio of 1:1, and the component A includes the following raw materials in parts by weight:

[0100]

[0101] B component comprises the raw material of following weight portion:

[0102]

[0103]

[0104] The nano zinc oxide is spiny nano zinc oxide.

[0105] The corrosion inhibitor is compounded by weak acid and strong base salt and weak base and strong salt according to the molar ratio of 1:1.

[0106] The dispersion stabilizer is prepared by compounding ethylene glycol ethyl ether, nonylphenol polyoxyethylene ether and polyoxyethylene ether in a mass ratio of 1:0.8:0.2.

[0107] The fluoride salt is ammonium fluoride.

[0108] The silicone oil is a mixture of methyl silicone oil and high hydrogen-containing silicone oil at a volume ratio of 1:1.

[0109] The moisturizing agent is a mixture composed of butylene glycol, glycerol and polyethylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com