Production process of amphiphilic silicon oxide-chitosan composite aerogel

A composite airgel and composite gel technology, applied in the field of amphiphilic silica-chitosan composite airgel production technology, can solve the problems of secondary pollution of adsorbed oil, low processing efficiency, slow oil absorption speed, etc. Achieve accelerated removal, good pore connectivity and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of production technology of amphiphilic silicon oxide-chitosan composite airgel, specifically comprises the following steps:

[0031] (1) Modification of chitosan

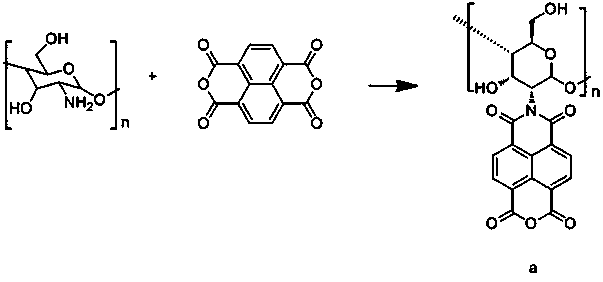

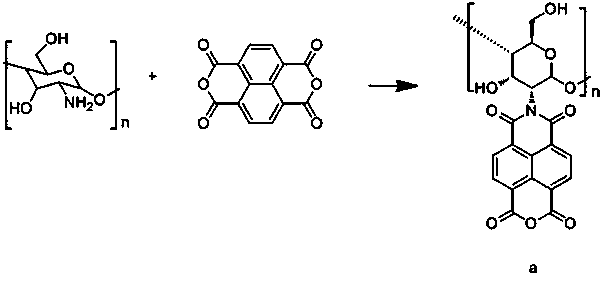

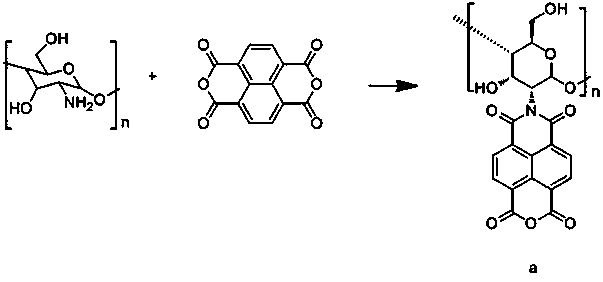

[0032] The reaction formula is as follows:

[0033]

[0034] Dissolve 1g of chitosan in 100ml of 2% acetic acid solution to obtain a chitosan solution; dissolve naphthalene-1,4,5,8-tetracarboxylic dianhydride in DMF solution to form a 40-50% Naphthalene acid solution, mix naphthalene acid solution with chitosan solution, add HOBT / EDCI and triethylamine, the addition of HOBT / EDCI is 1.1 times of the molar weight of naphthalene acid, the addition of triethylamine is the molar weight of naphthalene acid 1.5 times of that; stirred at 35°C for 2 hours, adjusted the pH of the solution to 7.5, precipitated, filtered, and washed with purified water to obtain naphthoic acid-grafted chitosan with a structure of formula a, and dissolved the washed precipitate in 100ml of 2% In the acetic acid solution, conf...

Embodiment 2

[0046] A kind of production technology of amphiphilic silicon oxide-chitosan composite airgel, specifically comprises the following steps:

[0047] (1) Modification of chitosan

[0048] Dissolve 1g of chitosan in 100ml of 2% acetic acid solution to obtain a chitosan solution; dissolve naphthalene-1,4,5,8-tetracarboxylic dianhydride in DMF solution to form 50% naphthalene acid Solution, mix naphthalene acid solution with chitosan solution, add HOBT / EDCI and triethylamine, the addition of HOBT / EDCI is 1.1 times of the molar weight of naphthalene acid, the addition of triethylamine is 1.5 times of the molar weight of naphthalene acid Stir at 40°C for 2 hours, adjust the pH of the solution to 8.0, precipitate out, filter, and wash with purified water to obtain naphthoic acid-grafted chitosan with a structure of formula a, dissolve the washed precipitate in 100ml of 2% acetic acid In the solution, it is configured into a chitosan solution;

[0049] The reaction formula is as foll...

Embodiment 3

[0061] A kind of production technology of amphiphilic silicon oxide-chitosan composite airgel, specifically comprises the following steps:

[0062] (1) Modification of chitosan

[0063] The reaction formula is as follows:

[0064]

[0065] Dissolve 1g of chitosan in 100ml of 2% acetic acid solution to prepare a chitosan solution; dissolve naphthalene-1,4,5,8-tetracarboxylic dianhydride in DMF solution to form 45% naphthalene acid Solution, mix naphthalene acid solution with chitosan solution, add HOBT / EDCI and triethylamine, the addition of HOBT / EDCI is 1.1 times of the molar weight of naphthalene acid, the addition of triethylamine is 1.5 times of the molar weight of naphthalene acid Stir at 38°C for 2 hours, adjust the pH of the solution to 7.7, precipitate out, filter, and wash with purified water to obtain naphthoic acid-grafted chitosan with a structure of formula a, dissolve the washed precipitate in 100ml of 2% acetic acid In the solution, it is configured into a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com