Wood-plastic composite material and preparation method thereof

A wood-plastic composite material and wood powder technology, applied in the field of wood-plastic materials, can solve problems such as deformation and bending, and achieve the effects of reducing processing temperature, prolonging the temperature range of decomposition, and avoiding untimely cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

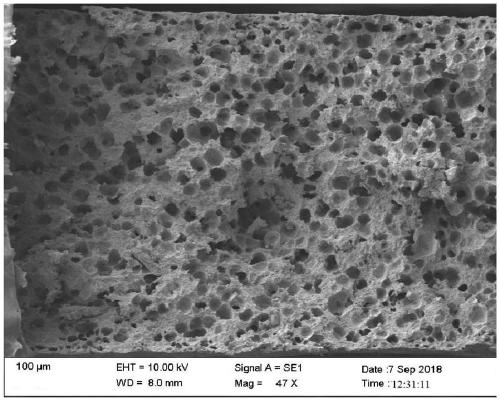

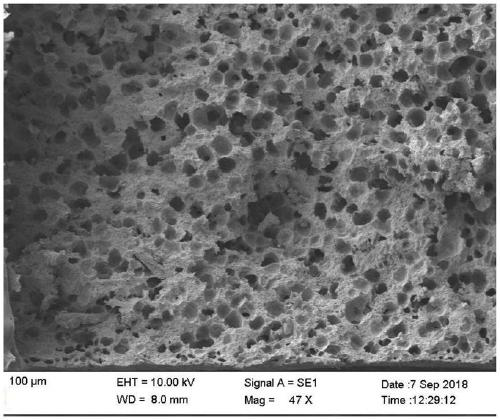

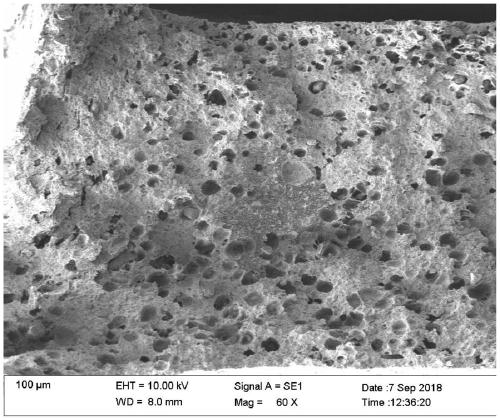

Image

Examples

preparation example Construction

[0067] And the preparation method of the foaming agent is:

[0068] It includes the following steps:

[0069] S1: Azodicarbonamide, sodium bicarbonate, and stearic acid to obtain a matrix mixture;

[0070] S2: Preparation of resin emulsion: mix acrylonitrile, acrylate monomer, emulsifier, bicarbonate and chain initiator in a solvent, and after vacuuming and exhausting oxygen, react at 25-40℃ for 60-240min to obtain Resin emulsion

[0071] S3: Use the resin emulsion as a spray solution to disperse the resin emulsion into small liquid particles through ultrasonic waves in the nozzle, and spray them from the nozzle in the form of mist, and the sprayed solution will evenly fall on the matrix mixture under the flow and stirring state; after curing treatment , Cool to room temperature;

[0072] The resin emulsion adopts an automatic sampling process, and the automatic sampling process is: flow: 30-45 μL / min; dispensing time: 90-110s; dispensing volume: 40-60 μL; interval time: 0.1 min; syri...

Embodiment 1

[0078] A preparation method of wood-plastic composite material includes the following steps:

[0079] PVC base material is 36%, wood powder is 15.5%, calcium powder is 25.7%, synergist 15.7%, foaming agent 0.1%, stabilizer 2.5%, coupling agent 1%, PVC processing aid 2%, lubricant 1.5%, mixed configuration into intermediate pellets;

[0080] Wherein, the foaming agent A includes: 60 parts of azodicarbonamide, 25 parts of sodium bicarbonate, and 2 parts of stearic acid.

[0081] The azodicarbonamide particles have a diameter of 1 μm.

[0082] Extrusion molding through twin screw extruder;

[0083] Wherein, the processing temperature of the twin screw extruder is:

[0084] The temperature of the first section of the barrel is: 120℃, and the temperature of the first section of the machine head is: 175℃;

[0085] The temperature of the second section of the barrel is: 165℃, and the temperature of the second section of the machine head is: 170℃;

[0086] The temperature of the third section of ...

Embodiment 2

[0090] A preparation method of wood-plastic composite material includes the following steps:

[0091] PVC base material is 44%, wood powder is 5%, calcium powder is 35%, synergist 10%, foaming agent 1%, stabilizer 1.3%, coupling agent 0.2%, PVC processing aid 3%, lubricant 0.5%, mixed and configured into intermediate pellets;

[0092] Wherein, the foaming agent A includes: 95 parts of azodicarbonamide, 15 parts of sodium bicarbonate, and 5 parts of stearic acid.

[0093] The diameter of the azodicarbonamide particles is 3 μm.

[0094] Extrusion molding through twin screw extruder;

[0095] Wherein, the processing temperature of the twin screw extruder is:

[0096] The temperature of the barrel in the first stage is 150℃, and the temperature of the head in the first stage is 160℃;

[0097] The temperature of the second section of the barrel is: 185℃, and the temperature of the second section of the machine head is: 175℃;

[0098] The temperature of the third section of the barrel is: 185℃,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com