A kind of acrylate emulsion and its preparation method and application

An acrylate and emulsion technology, applied in latex paints, coatings, etc., can solve the problem of not paying attention to the freeze-thaw stability, film-forming properties and other properties of latex paints, affecting scrub resistance, freeze-thaw stabilizers and low-temperature film-forming properties. , Affecting polymer adhesion, water resistance, freeze-thaw stability, etc., to achieve the effect of enhancing freeze-thaw stability and ionic stability, improving wrapping ability, improving integrity and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

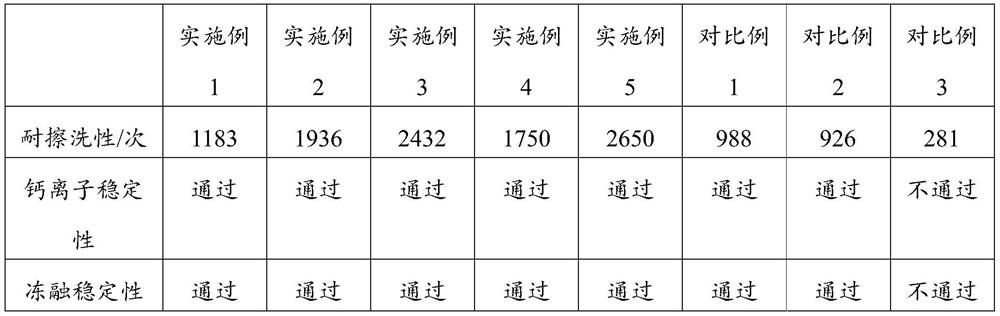

Examples

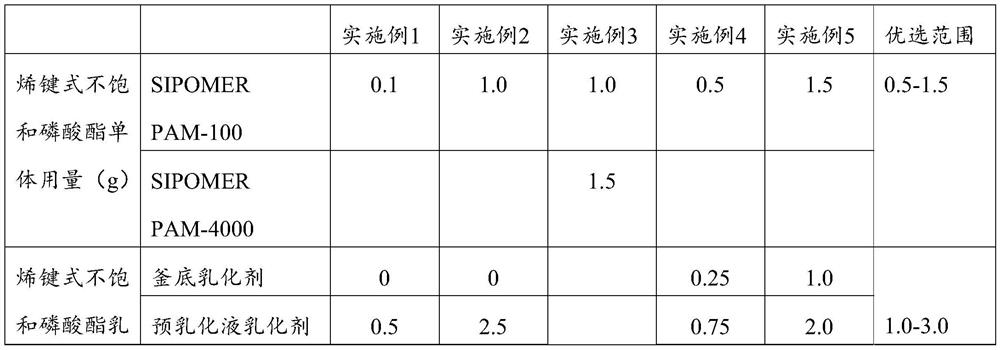

Embodiment 1

[0079]Weigh each raw material according to the following mass: styrene 40g, n-butyl acrylate 30g, acrylic acid 0.5g, acrylamide 2.0g, diacetone acrylamide 1.5g, SIPOMER PAM-100 0.1g, n-dodecyl mercaptan 0.01g , Maxemul 61060.5g, ammonium persulfate 0.2g, tert-butyl hydroperoxide 0.1g, erythorbic acid 0.05g and an appropriate amount of NaOH and deionized water.

[0080] 1) Preparation of pre-emulsion A: under normal temperature and pressure, add 0.5g Maxemul 6106 and 35g deionized water to the pre-emulsion tank with monomer metering tank and agitator, after fully stirring and dissolving, add 40g styrene in turn , 30g n-butyl acrylate, 0.5g acrylic acid, 90% acrylamide (ie 1.8g acrylamide), 1.5g diacetone acrylamide and 0.1g SIPOMERPAM-100, fully stirred for 20-30 minutes for use;

[0081] 2) preparation of bottom liquid B: in the polymerization still with stirrer, condenser, constant-flow pump feeding device, add remaining acrylamide (i.e. 0.2g acrylamide) and 50g deionized wat...

Embodiment 2

[0086] Weigh each raw material according to the following masses: 51 g of styrene, 30 g of n-butyl acrylate, 10 g of isooctyl acrylate, 2.0 g of acrylic acid, 0.25 g of acrylamide, 0.75 g of diacetone acrylamide, 1.0 g of SIPOMER PAM-1001.0 g, n-dodecane thiol 0.05g, Maxemul 6106 2.5g, ammonium persulfate 0.5g, tert-butyl hydroperoxide 0.5g, erythorbic acid 0.25g and appropriate amount of NaOH and deionized water.

[0087] 1) Preparation of pre-emulsion A: under normal temperature and pressure, add 2.5g of Maxemul 6106 and 35g of deionized water to the pre-emulsion tank with monomer metering tank and agitator, after fully stirring and dissolving, add 51g of styrene in turn. , 30g n-butyl acrylate, 10g isooctyl acrylate, 2.0g acrylic acid, 90% acrylamide (ie, 0.23g acrylamide), 0.75g diacetone acrylamide and 1.0g SIPOMER PAM-100, stir well for 20-30 minutes spare;

[0088] 2) Preparation of bottom liquid B: in the polymerization kettle with a stirrer, a condenser, and a consta...

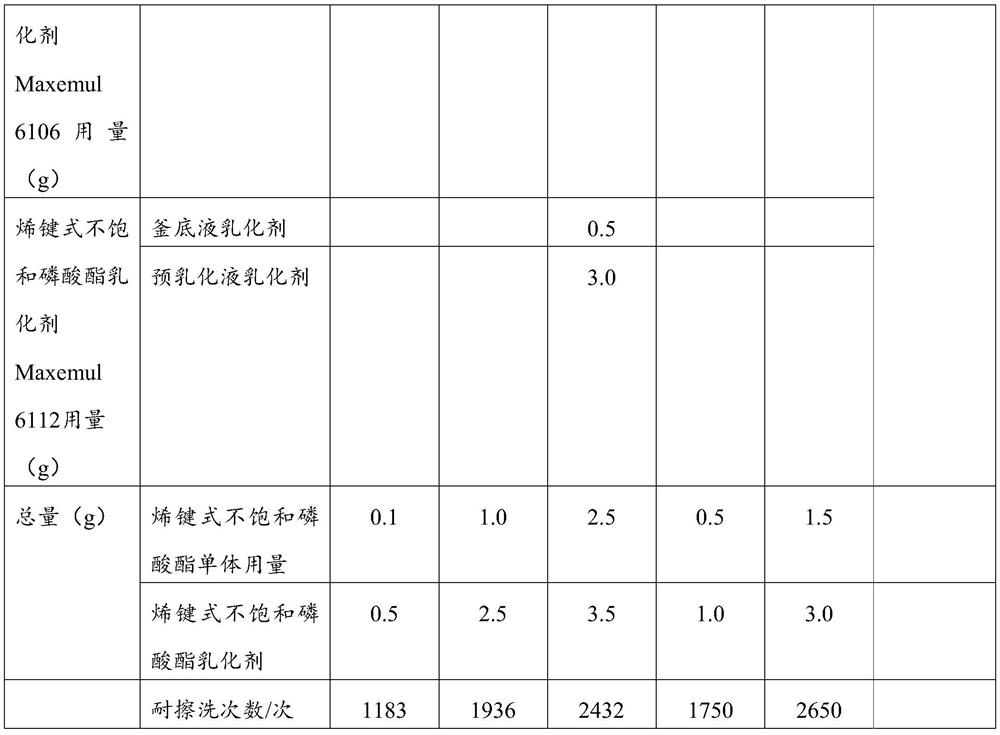

Embodiment 3

[0093] Weigh each raw material according to the following masses: 70 g of styrene, 60 g of n-butyl acrylate, 5.0 g of acrylic acid, 0.1 g of diacetone acrylamide, 1.0 g of SIPOMER PAM-100, 1.5 g of SIPOMER PAM-4000, n-dodecyl mercaptan 0.1 g, Maxemul 6112 3.5 g, ammonium persulfate 1.0 g, tert-butyl hydroperoxide 1.0 g, erythorbic acid 0.5 g and appropriate amount of NaOH and deionized water.

[0094] 1) Preparation of pre-emulsion A: under normal temperature and pressure, add 3.0g Maxemul 6112 and 55g deionized water to the pre-emulsion tank with monomer metering tank and agitator, after fully stirring and dissolving, add 70g benzene successively. Ethylene, 60g n-butyl acrylate, 5.0g acrylic acid, 0.1g diacetone acrylamide, 1.0g SIPOMER PAM-100 and 1.5g SIPOMER PAM-4000, stir well for 20-30 minutes for use;

[0095] 2) preparation of bottom liquid B: in the polymerization still with stirrer, condenser, constant flow pump feeding device, add remaining emulsifier Maxemul 6112 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com