Hydrophilic polyurethane carrier, preparation method thereof and application of carrier

A technology of hydrophilic polyurethane and polyurethane, which is applied in the direction of being fixed on/in the organic carrier, can solve the problems of long time for microorganisms to hang on the film, increase capital and labor costs, and easy detachment of microorganisms, and achieve good reactivity and Hydrophilic, beneficial for adsorption and immobilization, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

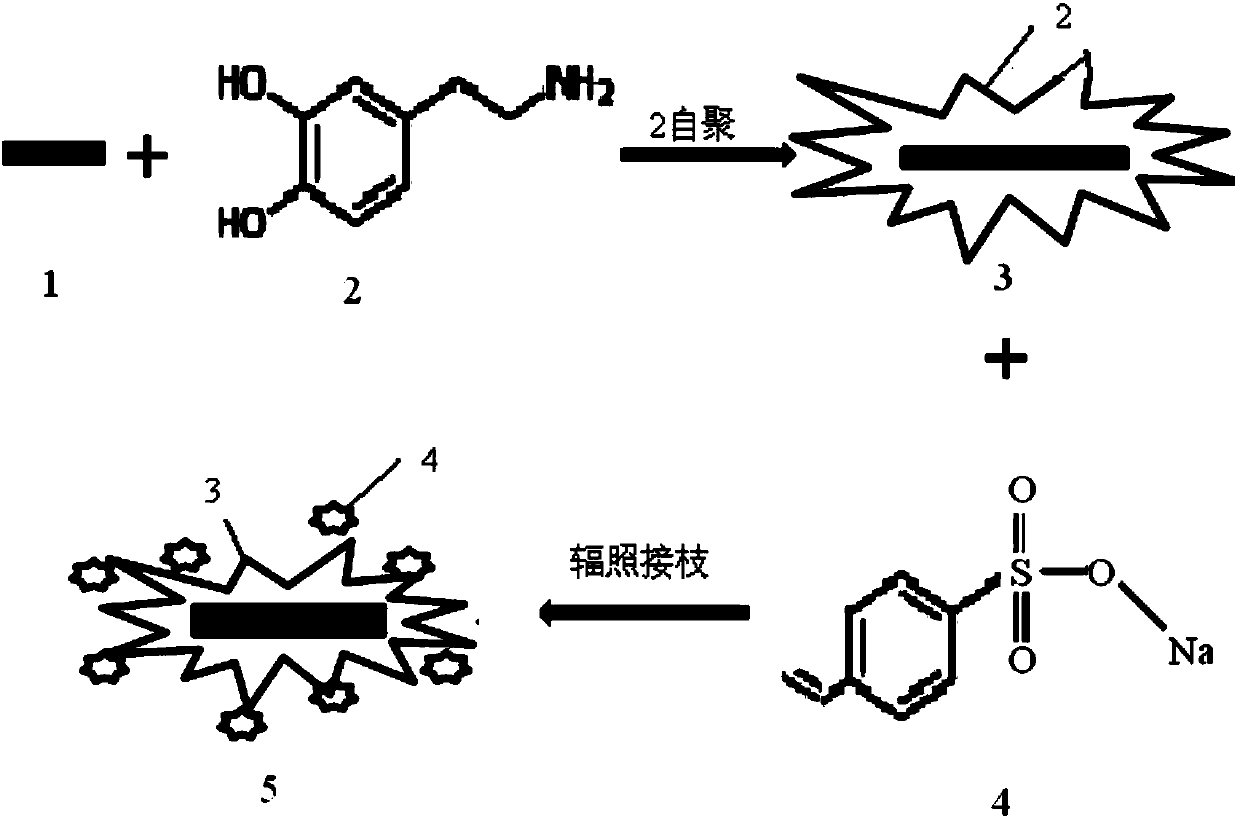

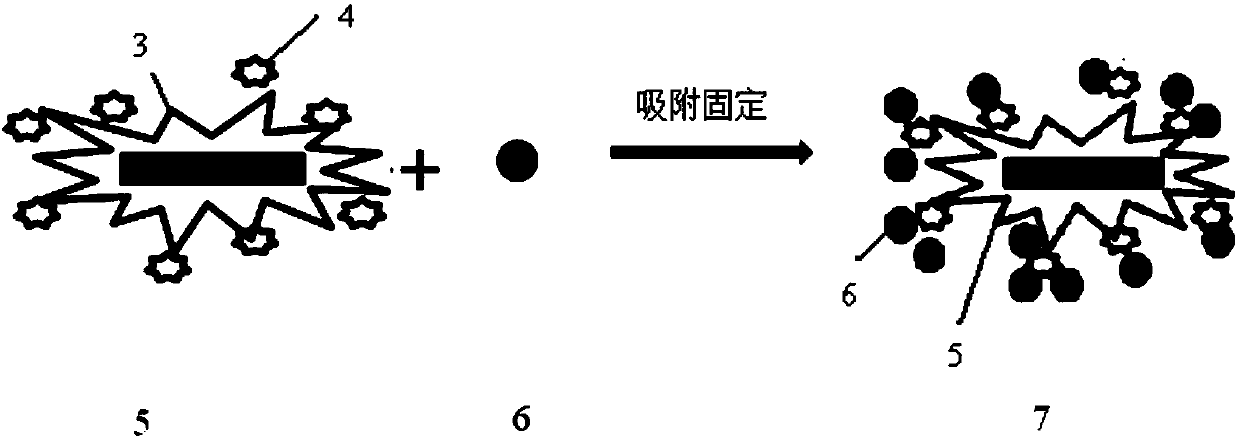

[0068] figure 1 A schematic flow diagram of the preparation method of the hydrophilic polyurethane carrier provided for a specific embodiment of the present invention; as figure 1 The steps shown include: step A: adding an oxidizing agent to the first prepolymer monomer solution prepared by the first prepolymer monomer and buffer to obtain the first prepolymer monomer modification solution, and then the polyurethane carrier Soak in the first prepolymer monomer modification solution, wash and dry to obtain a polyurethane carrier with a film-like first prepolymer on the surface; step B: coat the surface with a film-like The polyurethane carrier of the first prepolymer is soaked in the initiator solution, and then dried to obtain a hydrophilic polyurethane carrier precursor; step C: immersing the hydrophilic polyurethane carrier precursor into the second prepolymer monomer solution In the process, the light is irradiated, and the second prepolymer monomer and the hydrophilic pol...

preparation example 1

[0074] Prepare a 10mmol / L Tris-HCl solution, adjust the pH to 8, add dopamine and ammonium persulfate, the concentration is 2mg / mL, immerse a polyurethane cube with a side length of 20mm in the dopamine solution, soak for 2h; after soaking, take out The carrier is cleaned and dried with deionized water to complete the hydrophilic modification process of the polyurethane carrier; a methanol solution of 0.2mol / L benzophenone is prepared, and the dried polyurethane cube is immersed in the methanol solution of benzophenone , after soaking for 1 hour, take it out and dry it for later use; put the dried polyurethane carrier into an ultraviolet light generating device, immerse it in 10% sodium styrene sulfonate monomer solution, take it out after 10 minutes of ultraviolet light irradiation, place it in distilled water and wash it clean, That is, a hydrophilic modified polyurethane carrier is obtained.

Embodiment 1

[0076] Put the above-mentioned modified carrier prepared in Preparation Example 1 into the aerobic reaction tank for biological denitrification experiment. The sludge concentration in the aerobic tank is 3.2g / L. Under the condition of sufficient aeration, it only takes 5 days to complete the surface of the carrier. And the internal hanging film, taking a chemical wastewater with a COD of 730mg / L and an ammonia nitrogen of 115mg / L as the influent, the removal rate of COD can reach more than 94%, the removal rate of ammonia nitrogen can reach more than 99%, and the effluent COD is lower than 60mg / L, ammonia nitrogen lower than 2mg / L. Comparing the polyurethane carrier modified by sodium styrene sulfonate with the unmodified polyurethane carrier in Comparative Example 1, it was found that the fixed biomass can be increased by 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com