Quick yeast prepared from excellent aspergillus niger, rhizopus and saccharomycetes and method for producing Shanxi mature vinegar by cooperation of quick yeast and gigantic yeast

A technology for Aspergillus niger and yeast, applied in the field of microorganisms, can solve the problems of short cultivation time, high enzyme activity, single enzyme system, etc., and achieve the effects of good fermentation activity, good flavor and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation of composite fast song

[0022] (1) Cultivation of fungal koji species: Spot the fungus on PDA solid slant medium, culture at 30°C for 3–5 days, and use it as a test tube strain after the spores of the slant strain are mature. According to the inoculation amount of 2%, the mold spore suspension (the concentration of the spore suspension is 10 6 individual / mL) into the bran Erlenmeyer flask culture medium. 30 ℃ constant temperature culture. When cultured for about 18 hours, the bran medium was covered with white hyphae and agglomerated, and the triangular flask was shaken to loosen the agglomerated koji. After continuing to cultivate for 24‒25h, the koji in the Erlenmeyer flask will form a koji cake due to the mycelium covered. At this time, you need to tap the bottom of the Erlenmeyer flask with your hands to make the koji that is fixed and adhered to the bottom of the Erlenmeyer flask. The koji is loose. After continuing to cultivate f...

Embodiment 2

[0037] Embodiment 2: Utilize excellent Aspergillus niger, rhizopus, yeast to make fast song and cooperate Daqu to produce Shanxi mature vinegar

[0038] Crush the sorghum to four to six petals, add 60-70 kg of water at 50-55°C to 100 kg of sorghum to moisten the material for 12 hours, steam the moist sorghum for 2 hours, and stop the fire when it is not sticky to the hand; then add 300 kg of water at a temperature of 80°C water, stir evenly to soak the material, when the temperature drops to 25‒33°C, mix in 30 kg of Daqu and 30 kg of Kuaiqu, and after stirring evenly, transport it to the alcohol fermentation tank for alcohol fermentation for 8‒10 days (after measuring the temperature Change to 25‒33℃), the first 2 days is open-top fermentation, and then it is sealed fermentation. When the alcohol content is 6%, add 120 kg of bran and 80 kg of rice bran, stir well, and add 10 kg of fermented grains (upper A batch of vinegar fermented grains fermented on the second day) was subj...

Embodiment 3

[0039] Example 3: Taking Example 2 as a comparative example, add 300 kilograms of water at a temperature of 80°C according to the above method, stir and soak evenly, and when the temperature drops to 25-33°C, mix in 30 kilograms of Daqu and 30 kilograms of compound Fast song, after being stirred evenly, be transported to the alcohol fermenter and carry out alcohol fermentation for 8-10 days.

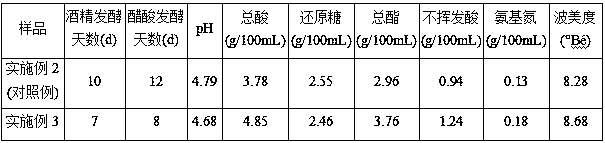

[0040] Compared with the production of Shanxi old mature vinegar by using high-quality Aspergillus niger, rhizopus and yeast, the compound fast koji produced by using ordinary fast koji, the fermentation cycle is significantly shortened, and the days of alcohol fermentation are shortened from 10 days to 7 days, and the days of acetic acid fermentation The number of days is shortened from 12 days to 8 days, which improves production efficiency. In Example 3, the total acid content was 4.85 g / 100mL, the non-volatile acid content was 1.24 g / 100mL, and the total ester content was 3.76 g / 100m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com