Functional mulberry leaf oligosaccharide and preparation method and application thereof

An oligosaccharide and functional technology, applied in the field of functional mulberry leaf oligosaccharide and its preparation and application, can solve the problems of low bioavailability, difficulty in absorption and utilization, high molecular weight and viscosity, etc., and achieve simplified separation and purification Process, promote the proliferation of intestinal beneficial bacteria, good economical and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

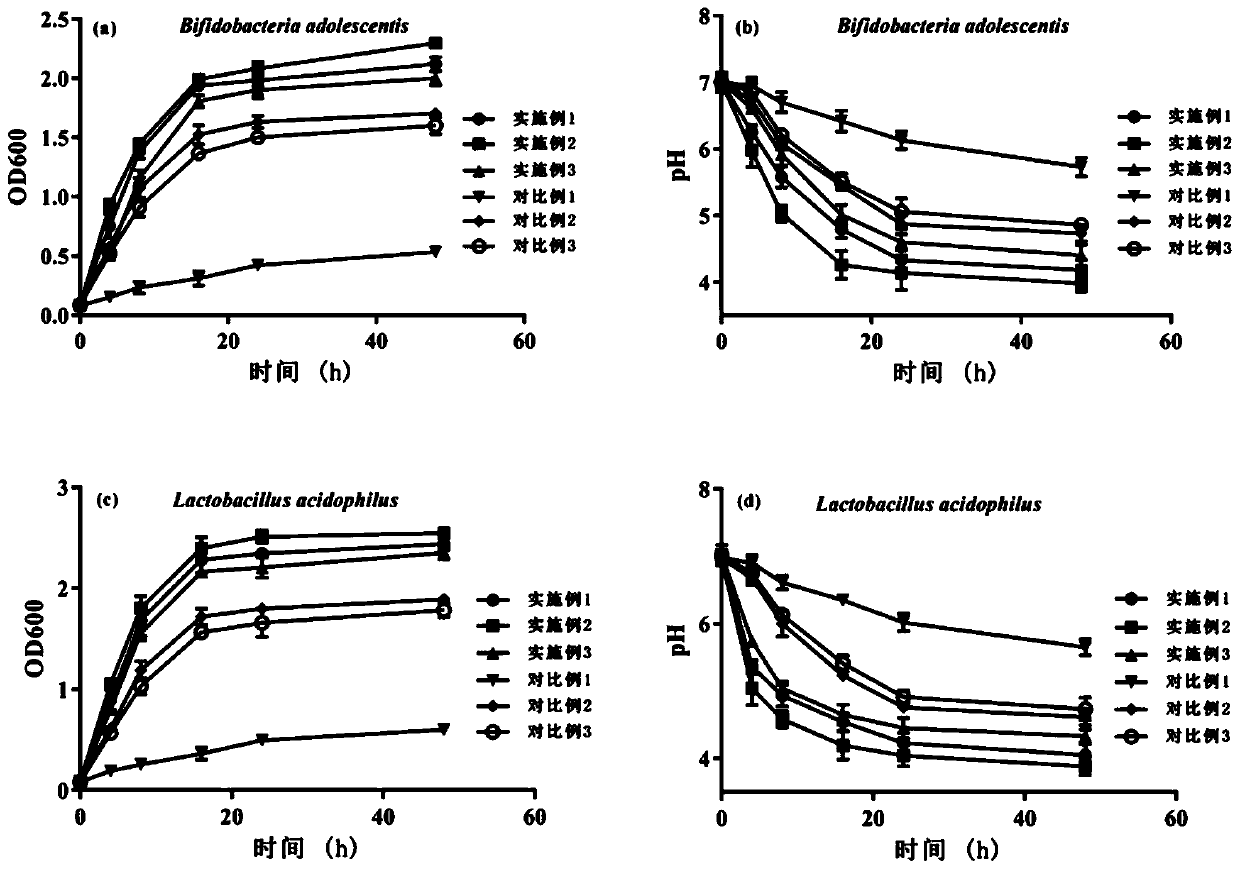

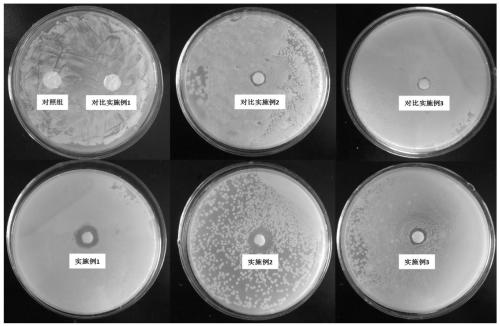

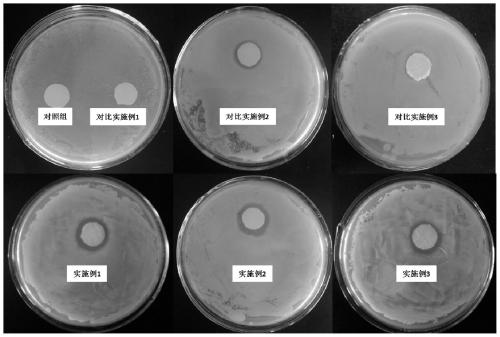

[0044] Weigh 500g of dry mulberry leaves (water content less than 5%), degrease with 2000mL petroleum ether after crushing. Separation and recovery of the extract and defatted mulberry leaf powder. Add all the mulberry leaf powder obtained by degreasing into 10L distilled water, extract at 90°C for 4 hours, filter the supernatant to obtain the mulberry leaf polysaccharide extract, concentrate the polysaccharide extract to a final concentration of 2%, and adjust the pH to 4.9.

[0045]Add 9.5 g of hemicellulase to 1 L of mulberry leaf polysaccharide concentrate, and stir in a constant temperature magnetic stirrer at 55° C. to carry out enzymolysis reaction. After 9 hours, the enzyme was inactivated at 100° C., and the supernatant was collected by filtration to obtain a crude mulberry leaf oligosaccharide reaction solution with a concentration of 19.8 mg / mL of oligosaccharides. Add 1 L of absolute ethanol (final concentration of ethanol is 50%) to the crude mulberry leaf oligos...

Embodiment 2

[0048] Weigh 500g of dry mulberry leaves (water content less than 5%), degrease with 2000mL petroleum ether after crushing. Separation and recovery of the extract and defatted mulberry leaf powder. Add all the mulberry leaf powder obtained by defatting to 7.14L distilled water, extract at 100°C for 5 hours, filter the supernatant to obtain the mulberry leaf polysaccharide extract, concentrate the polysaccharide extract to a final concentration of 2.5%, and adjust the pH to 5.0 .

[0049] Add 11 g of hemicellulase to 1 L of mulberry leaf polysaccharide concentrate, stir in a constant temperature magnetic stirrer at 55° C. to carry out enzymolysis reaction. After 10 hours, the enzyme was inactivated at 100° C., and the supernatant was collected by filtration to obtain a crude reaction solution of mulberry leaf oligosaccharides. The yield of oligosaccharides was 21.5 mg / mL. Add 1.86 L of absolute ethanol (final concentration of ethanol is 65%) to the crude mulberry leaf oligosa...

Embodiment 3

[0052] Weigh 500g of dry mulberry leaves (water content less than 5%), degrease with 2000mL petroleum ether after crushing. Separation and recovery of the extract and defatted mulberry leaf powder. Add all the mulberry leaf powder obtained by defatting to 16.7L distilled water, extract at 80°C for 3 hours, filter the supernatant to obtain the mulberry leaf polysaccharide extract, concentrate the polysaccharide extract to a final concentration of 2.0%, and adjust the pH to 4.8 .

[0053] Add 11 g of hemicellulase to 1 L of mulberry leaf polysaccharide concentrate, stir in a constant temperature magnetic stirrer at 55° C. to carry out enzymolysis reaction. After 8 hours, the enzyme was inactivated at 100° C., and the supernatant was collected by filtration to obtain a crude reaction solution of mulberry leaf oligosaccharides. The yield of oligosaccharides was 17.2 mg / mL. Add 1.22 L of absolute ethanol (final concentration of ethanol is 55%) to the crude mulberry leaf oligosacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com