Molybdenum carbide modified tubular carbon nitride photocatalytic material and preparation method and application thereof

A catalytic material and photocatalytic reaction technology, applied in the field of tubular carbon nitride photocatalytic materials and its preparation, can solve the problems of unremarkable photocatalytic performance, large-scale application limitations, low utilization rate of visible light, etc., and achieve superior photocatalytic activity , to achieve effective separation, easy transfer and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of tubular carbon nitride (Mo) modified by molybdenum carbide of the present invention 2 C / TCN) photocatalytic material, its preparation method comprises the following steps:

[0055] (1) Preparation of tubular carbon nitride:

[0056] 1.1. Grind 8.56g of urea and 6g of melamine, dissolve in 70ml of deionized water, and stir at a constant speed for 2 hours to obtain a uniform mixed solution.

[0057] 1.2. Transfer the above mixed solution to a 100mL autoclave, and keep it warm at 180°C for 24 hours. After natural cooling, rinse with water and ethanol three times respectively, filter, and dry at 100°C for 12h to obtain the carbon nitride precursor .

[0058] 1.3. Put the carbon nitride precursor into a crucible, place it in a muffle furnace, heat it up to 550°C at a heating rate of 2.3°C / min, and keep it at 550°C for 4 hours. The whole process is carried out under the protection of nitrogen. After natural cooling, it was taken out and ground with a mortar to ob...

experiment example 1

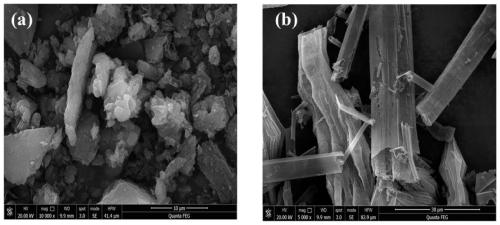

[0066] Experimental Example 1: The monomeric carbon nitride in Comparative Example 1 and the tubular carbon nitride in Example 1 were scanned by an electron microscope.

[0067] figure 1 It is a scanning electron microscope (SEM) illustration of the monomer carbon nitride of Comparative Example 1 of the present invention and the tubular carbon nitride of Example 1, wherein (a) is monomer carbon nitride, and (b) is tubular carbon nitride .

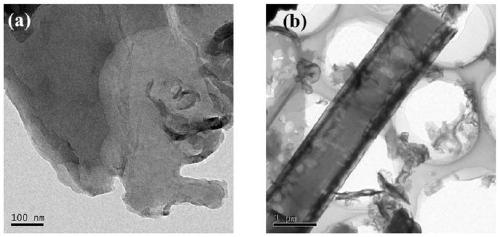

[0068] figure 2 It is a transmission electron microscope (TEM) illustration of the monomeric carbon nitride of Comparative Example 1 of the present invention and the tubular carbon nitride of Example 1, wherein (a) is a monomeric carbon nitride, and (b) is a hollow tubular carbon nitride carbon.

[0069] From figure 1 and figure 2 It can be seen that the monomeric carbon nitride presents a block-like aggregated structure with a small specific surface area and no nanopores on the surface. However, the tubular carbon nitride presents ...

experiment example 2

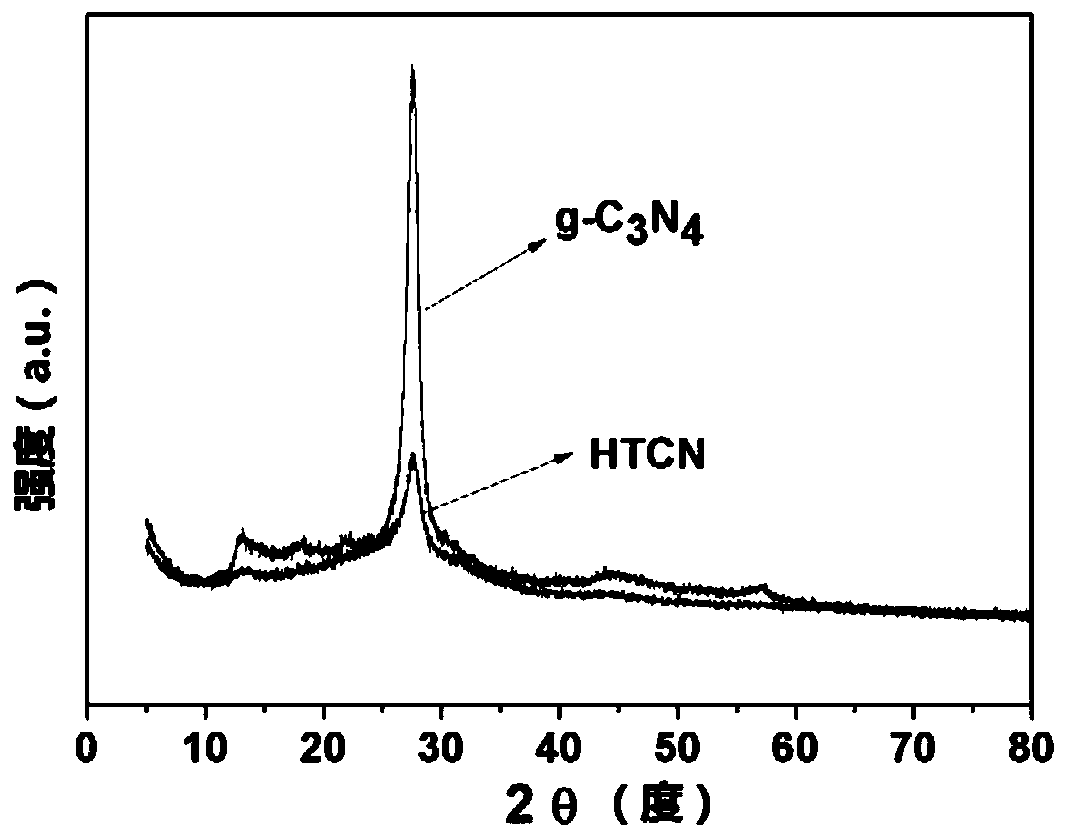

[0070] Experimental example 2: the monomer carbon nitride of comparative example 1, the tubular carbon nitride in embodiment 1, molybdenum carbide and Mo 2 X-ray scanning of C / TCN composites.

[0071] image 3 It is the X-ray diffraction (XRD) comparative pattern of the monomeric carbon nitride of Comparative Example 1 of the present invention and the tubular carbon nitride of Example 1. From the figure, it can be found that there are two obvious XRD diffraction peaks at 13.1° and 27.2° that belong to the graphitic carbon nitride (100) and (002) crystal planes, confirming that the prepared product is g-C 3 N 4 . Compared with monomeric carbon nitride, the 27.2° peak of tubular carbon nitride becomes wider and its intensity becomes weaker, indicating that its crystal form becomes weaker, its thickness becomes thinner, and a hollow tubular structure is successfully formed.

[0072] Figure 4 Tubular carbon nitride, molybdenum carbide and Mo of embodiment 1 2 C / TCN composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com