A kind of boron-doped cobalt hydroxide loaded on porous copper substrate multi-level structure material and preparation method thereof

A technology of cobalt hydroxide and structural materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., to improve reaction activity, large reaction activity area, and facilitate electron transport Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a multi-level structure material loaded with boron-doped cobalt hydroxide on a porous copper substrate, comprising the following steps:

[0031] (1) Cut the foamed nickel mesh with an effective size of 20cm*8cm as the substrate, degrease with 1M soda ash solution, pickle with 1M hydrochloric acid, rinse with deionized water until neutral, and set aside;

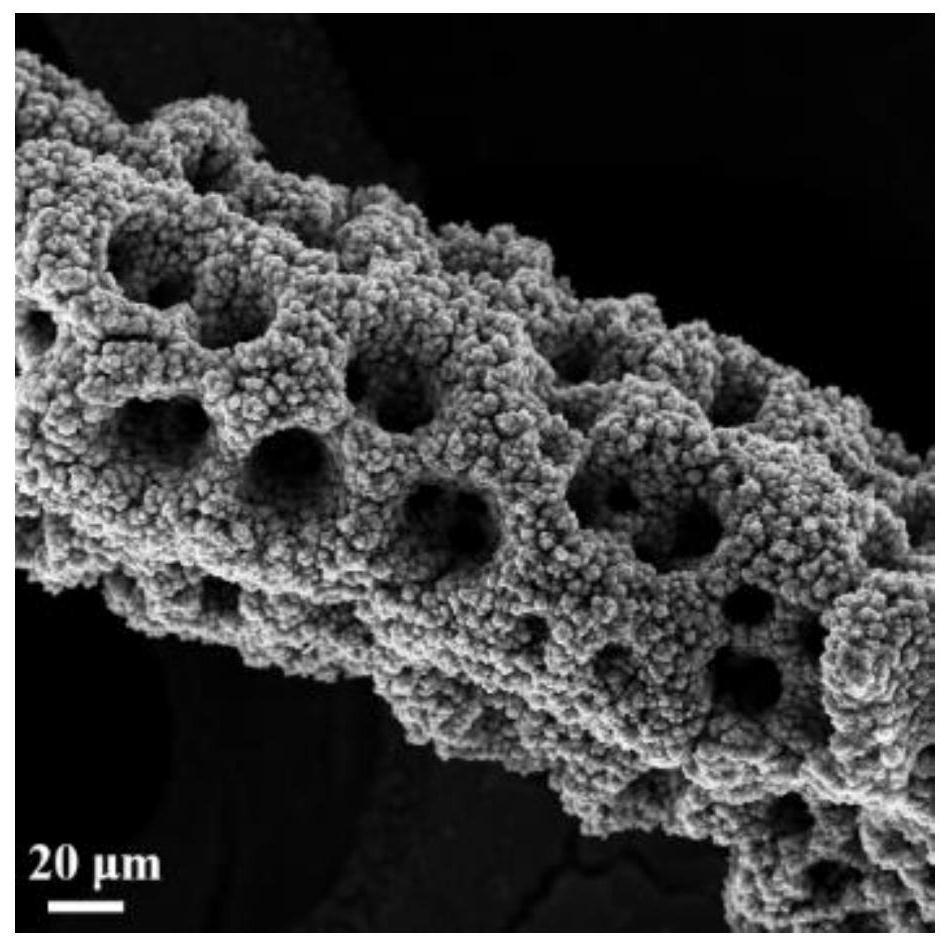

[0032] (2) at 2M H 2 SO 4 , 1M CuSO 4 In the solution, with nickel foam as the cathode, apply 2000mA / cm 2 High current 600s, get porous copper / nickel foam; strong acid solution can avoid OH - Too much to prevent the formation of copper hydroxide;

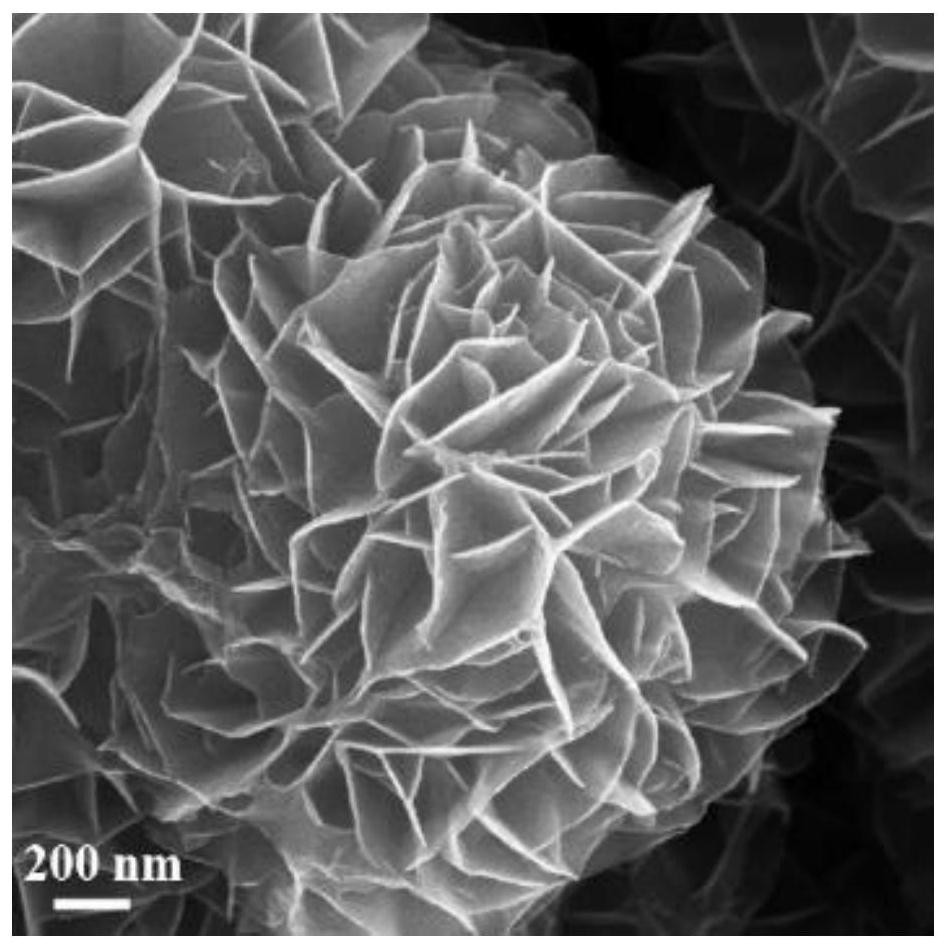

[0033] (3) Using porous copper / nickel foam as cathode material, Co(NO 3 ) 2 In the solution, apply a small current of 10mA / cm 2 By 120s, cobalt hydroxide nanosheets were electrodeposited on the porous copper to obtain cobalt hydroxide nanosheets / porous copper / nickel foam;

[0034] (4) With cobalt hydroxide nanosheet / porous copper / nickel foam as...

Embodiment 2

[0037] A method for preparing a multi-level structure material loaded with boron-doped cobalt hydroxide on a porous copper substrate, comprising the following steps:

[0038] (1) Cut titanium mesh with an effective size of 20cm*20cm as the substrate, degrease with 1M soda ash solution, pickle with 1M hydrochloric acid, rinse with deionized water until neutral, and set aside;

[0039] (2) at 1.5M H 2 SO 4 , 0.8M CuSO 4 In the solution, with the titanium mesh as the cathode, apply 1000mA / cm 2 High current 480s, get porous copper / titanium mesh; strong acid solution can avoid OH - Too much to prevent the formation of copper hydroxide;

[0040] (3) Using porous copper / titanium mesh as cathode material, Co(NO 3 ) 2 solution, apply a small current of 20mAcm -2 By 60s, electrodeposit cobalt hydroxide nanosheets on the porous copper to obtain cobalt hydroxide nanosheets / porous copper / titanium mesh;

[0041] (4) Cobalt hydroxide / porous copper / titanium mesh is used as the cathode...

Embodiment 3

[0043] A method for preparing a multi-level structure material loaded with boron-doped cobalt hydroxide on a porous copper substrate, comprising the following steps:

[0044] (1) Cut the nickel mesh with an effective size of 10cm*20cm as the substrate, degrease with 1M soda ash solution, pickle with 1M hydrochloric acid, rinse with deionized water until neutral, and set aside;

[0045] (2) at 1.5M H 2 SO 4 , 1.2M CuSO 4 In the solution, with the cleaned nickel mesh as the cathode, apply 2000mA / cm 2 High current 200s, get porous copper / nickel mesh; strong acid solution can avoid OH - Too much to prevent the formation of copper hydroxide;

[0046] (3) Co(NO 3 ) 2In the solution, apply a small current of 10mA / cm 2 Up to 90s, electrodeposit cobalt hydroxide nanosheets on the above-mentioned porous copper to obtain cobalt hydroxide nanosheets / porous copper / nickel mesh;

[0047] (4) Cobalt hydroxide / porous copper / nickel mesh is used as cathode, in 1M NaBH 4 solution, carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com