Method for preparing copper zinc tin sulfur film by vulcanization annealing in air

A copper-zinc-tin-sulfur and sulfide annealing technology, applied in electrical components, climate sustainability, final product manufacturing, etc., can solve the problems of high requirements for annealing equipment, high cost, and unfavorable large-scale production of copper-zinc-tin-sulfur thin films. , to achieve the effect of low raw material cost, low cost and uncomplicated equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

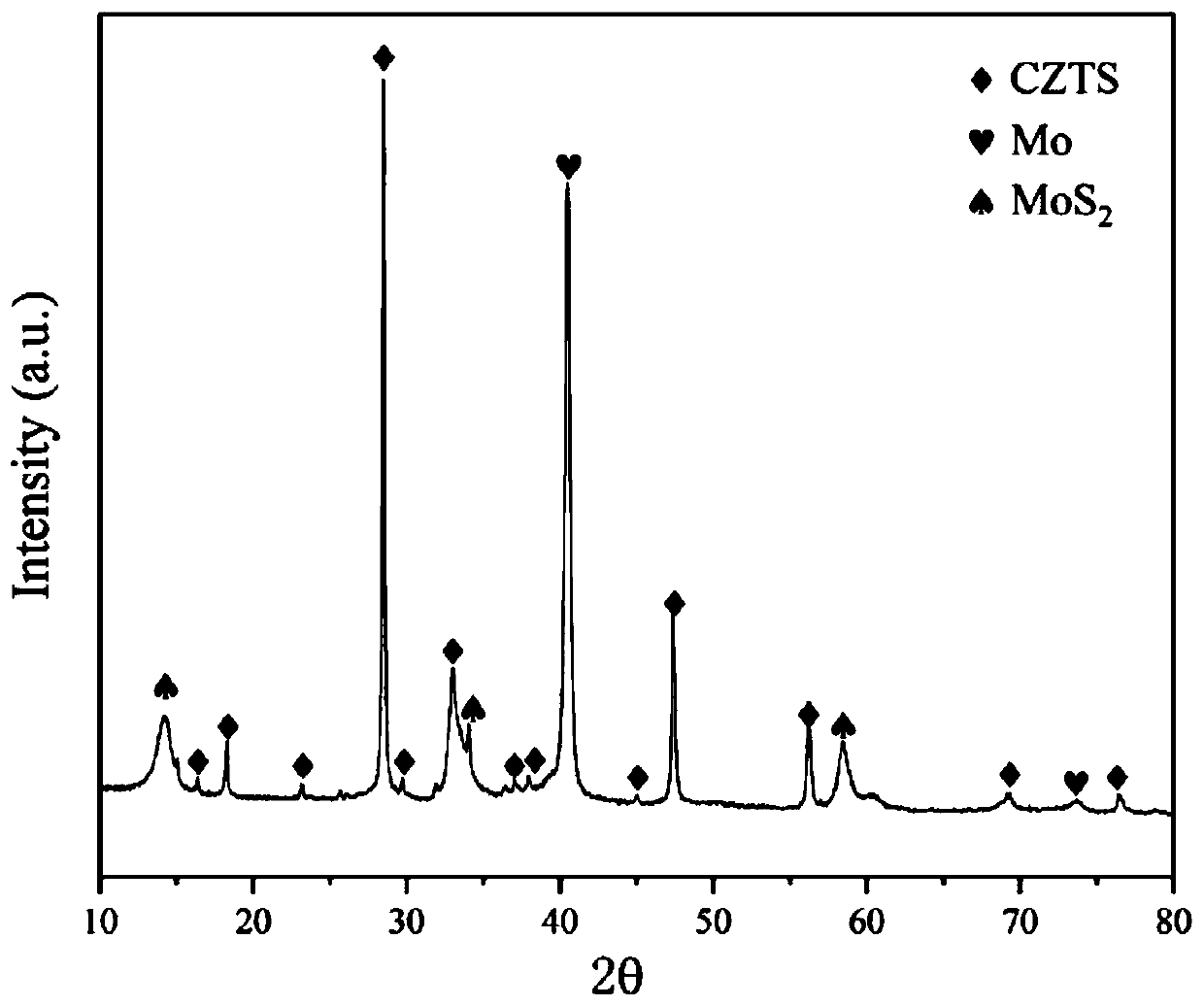

[0037] A method for preparing copper-zinc-tin-sulfur thin film by sulfidation annealing in air:

[0038] 1. Immerse the molybdenum-coated glass substrate in common detergent, deionized water, ethanol, and acetone solution in turn, and then ultrasonically clean the deionized water, and clean CuO, ZnO, and SnO 2 The mixed slurry (concentration is 200mg / ml, n(Cu) / n(Sn+Zn)=0.8, n(Zn) / n(Sn)=1.2)) is coated on the surface of molybdenum-coated glass by knife scraping method, Obtain an oxide precursor film;

[0039] 2. Seal the above-mentioned oxide precursor film and 0.3g of sulfur powder in an air environment into a quartz tube with an inner diameter of 2.5cm and a length of 15cm;

[0040]3. After sealing the quartz tube, perform high-temperature heat treatment. Select the tube furnace as the heating source, so that the sulfur powder and the oxide precursor film can be heated from room temperature at the same time. The heating rate is 40°C / min, and finally kept at 580°C. After slo...

Embodiment 2

[0043] A method for preparing copper-zinc-tin-sulfur thin film by sulfidation annealing in air:

[0044] 1. Immerse the soda-lime glass substrate in common detergent, deionized water, ethanol, and acetone solution in sequence, and then ultrasonically clean the deionized water, and clean CuO, ZnO, and SnO 2 The mixed slurry (concentration is 200mg / ml, n(Cu) / n(Sn+Zn)=0.8, n(Zn) / n(Sn)=1.2)) is coated on the surface of soda lime glass by knife scraping method, Obtain an oxide precursor film;

[0045] 2. Seal the above-mentioned oxide precursor film and 0.2g of sulfur powder in an air environment in a quartz tube with an inner diameter of 2cm and a length of 10cm;

[0046] 3. Seal the above-mentioned quartz tube and carry out high-temperature heat treatment. Select a tube furnace as the heating source, so that the sulfur powder and the oxide film start to heat up from room temperature at the same time. The heating rate is 40°C / min, and finally kept at 530°C. After slowly cooling ...

Embodiment 3

[0048] A method for preparing copper-zinc-tin-sulfur thin film by sulfidation annealing in air:

[0049] 1. Immerse the molybdenum-coated glass substrate in common detergent, deionized water, ethanol, and acetone solution in sequence, and then ultrasonically clean the deionized water, and clean CuO, ZnO, and SnO 2 The mixed slurry (concentration is 200mg / ml, n(Cu) / n(Sn+Zn)=0.8, n(Zn) / n(Sn)=1.2)) is coated on the surface of molybdenum-coated glass by knife scraping method, Obtain an oxide precursor film;

[0050] 2. Seal the above-mentioned oxide precursor film and 0.6g of sulfur powder in an air environment in a quartz tube with an inner diameter of 3cm and a length of 25cm;

[0051] 3. After sealing the above-mentioned quartz tube, perform high-temperature heat treatment. Select a tube furnace as the heating source, so that the sulfur powder and the oxide film are heated from room temperature at the same time, the heating rate is 40°C / min, and finally kept at 600°C, kept fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com