Preparation method and application of heteroelement-doped carbon nano tube packaging metal sulfide composite negative electrode material

A technology of metal sulfide and carbon nanotubes, applied in electrical components, battery electrodes, electrochemical generators, etc., to achieve improved cycle performance, good industrialization prospects, and reduced polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

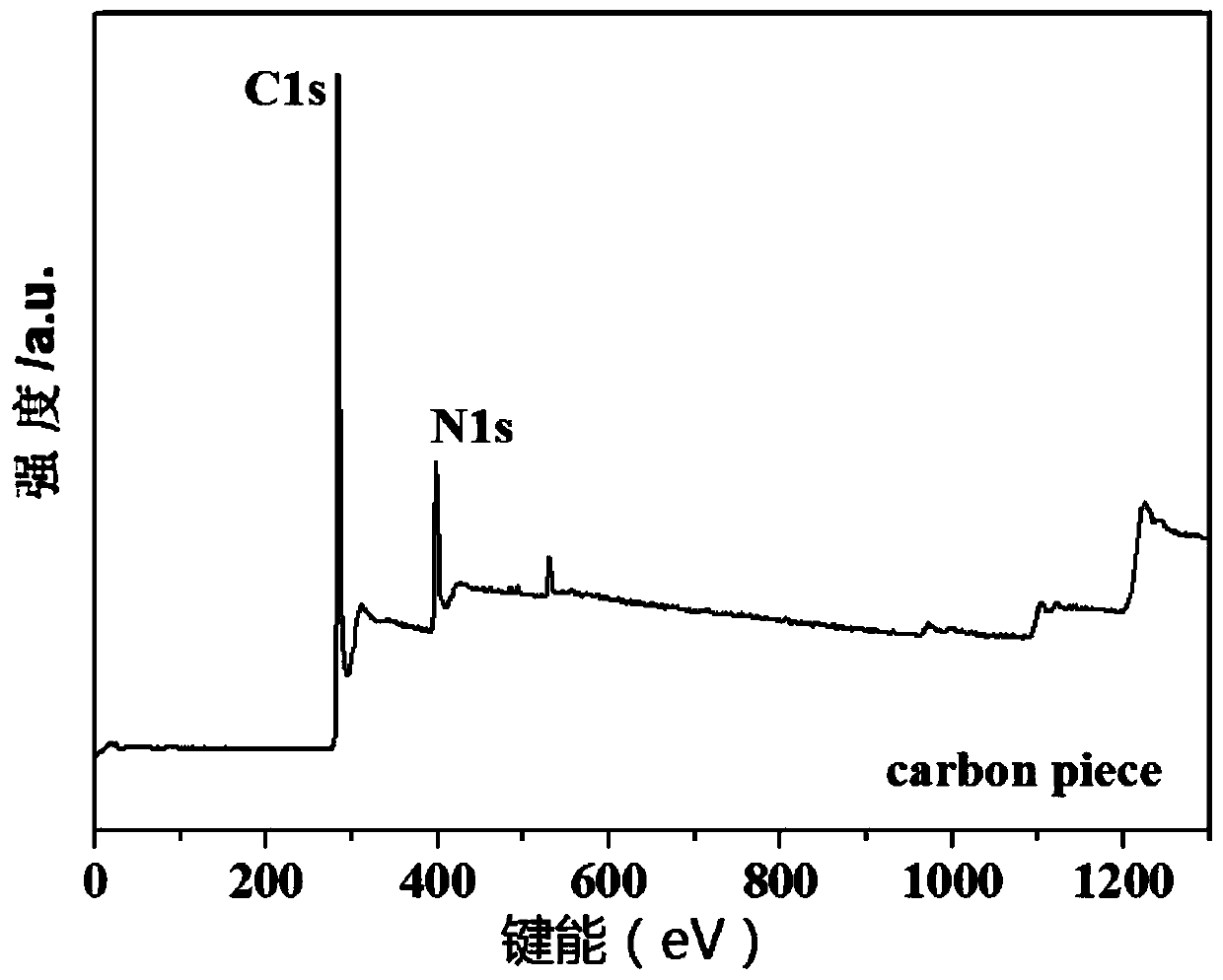

[0022] A method for preparing a heteroelement-doped carbon nanotube-encapsulated metal sulfide composite negative electrode material, comprising the following steps:

[0023] 1) Prepare 100 mL of a mixed solution of absolute ethanol and water, the volume ratio of water and ethanol is 9:1;

[0024] 2) Disperse 3g of cyanoamine in the above mixed solution. After ultrasonic dissolution is complete, add 0.3g of ferric sulfate. After ultrasonication for 20 minutes, add 0.3g of fructose to ultrasonically dissolve completely, remove the solvent by rotary evaporation, and then Precursor powder is prepared by vacuum drying;

[0025] 3) Transfer the precursor powder into a tube furnace, raise the temperature to 600°C at a rate of 2°C / min under argon, keep it for two hours, then raise it to 800°C at a rate of 2°C / min, and keep it After cooling down to room temperature for two hours, a black powder is obtained, which is the carbon nanotube-encapsulated iron nanoparticle composite materia...

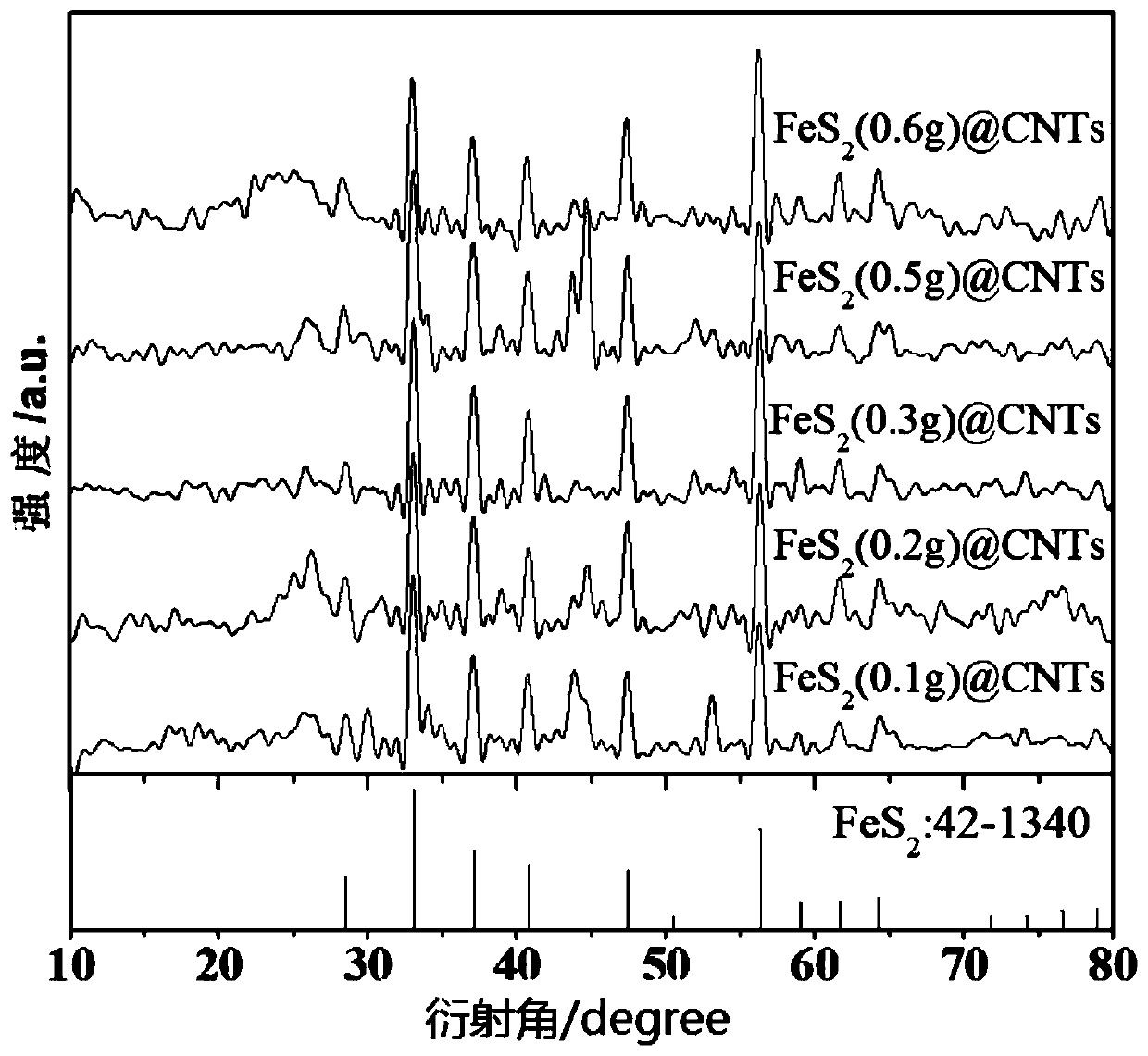

Embodiment 2

[0029] A method for preparing a heteroelement-doped carbon nanotube-encapsulated metal sulfide composite negative electrode material, comprising the following steps:

[0030] 1) Prepare 200 mL of a mixed solution of absolute ethanol and water, and the ratio of water to ethanol is 19:1;

[0031] 2) Disperse 3 g of cyanoamine in the above mixed solution. After ultrasonic dissolution is complete, add 0.6 g of ferric sulfate. After ultrasonication for 20 minutes, add 0.3 g of fructose to dissolve completely by ultrasonic, remove the solvent by rotary evaporation, and then Precursor powder is prepared by vacuum drying;

[0032] 3) Put the above precursor powder into the tube furnace, raise the temperature to 600°C at a rate of 2°C / min under argon, keep it for two hours, and then raise the temperature to 800°C at a rate of 2°C / min, After two hours of heat preservation, it was lowered to room temperature to obtain a black powder, which is a carbon nanotube-encapsulated iron nanopart...

Embodiment 3

[0036] A method for preparing a heteroelement-doped carbon nanotube-encapsulated metal sulfide composite negative electrode material, comprising the following steps:

[0037] 1) Prepare 200 mL of a mixed solution of absolute ethanol and water, and the ratio of water to ethanol is 15:1.

[0038] 2) Disperse 3 g of cyanoamine in the above mixed solution. After ultrasonic dissolution is complete, add 0.1 g of ferric sulfate. After ultrasonication for 20 minutes, add 0.3 g of fructose to dissolve completely by ultrasonic, remove the solvent by rotary evaporation, and then Precursor powder is prepared by vacuum drying;

[0039] 3) Put the above precursor powder into the tube furnace, raise the temperature to 600°C at a rate of 2°C / min under argon, keep it for two hours, and then increase the temperature to 800°C at a rate of 2°C / min, After two hours of heat preservation, it was lowered to room temperature to obtain a black powder, which is a carbon nanotube-encapsulated iron nanop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com