High-toughness flame-retardant nylon material and preparation method thereof

A flame-retardant nylon and high-toughness technology, which is applied in the field of high-toughness flame-retardant nylon materials and their preparation, can solve the problems of nylon resin flame-retardant ability and poor toughness, and achieve improved mechanical properties, thermal oxygen stability, and gap Excellent impact strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

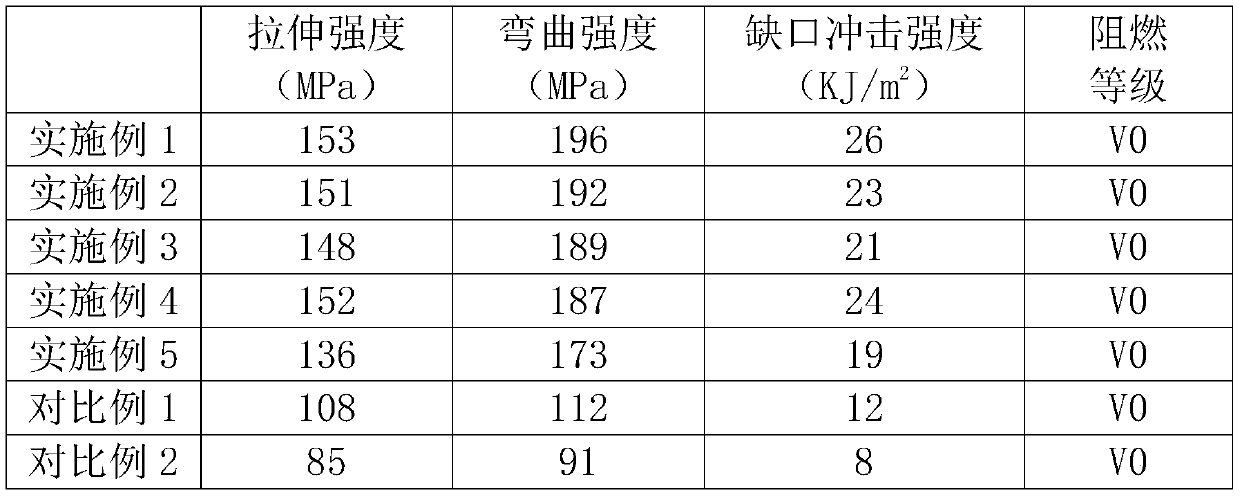

Examples

Embodiment 1

[0024] The present embodiment provides a high-toughness flame-retardant nylon material, comprising the following components by weight: 55 parts of nylon 66, 35 parts of glass fibers, 25 parts of DOPO-based nitrogen-phosphorus flame retardants, 8 parts of primary toughening agents, 3 parts of Part of auxiliary toughening agent, 1 part of thermotropic liquid crystal polymer, 0.5 part of antioxidant; the structural formula of the DOPO-based nitrogen-phosphorus flame retardant is as follows: R is 1,4'-phenylene, the primary toughening agent is methyl methacrylate-butyl acrylate core-shell copolymer, the secondary toughening agent is polybutylene succinate, and the glass The fiber is a glass fiber surface-treated with a titanate coupling agent, and the titanate coupling agent is tris(dioctylpyrophosphoryloxy) isopropyl titanate, and the melting point of the thermotropic liquid crystal polymer is at 270°C, the antioxidant is composed of hindered phenolic antioxidant and phosphite a...

Embodiment 2

[0030] The present embodiment provides a high-toughness flame-retardant nylon material, comprising the following components by weight: 50 parts of nylon 6, 30 parts of glass fiber, 15 parts of DOPO-based nitrogen-phosphorus flame retardant, 5 parts of main toughening agent, 5 parts of part of auxiliary toughening agent, 0.5 part of thermotropic liquid crystal polymer, and 1 part of antioxidant; the structural formula of the DOPO-based nitrogen-phosphorus flame retardant is as follows: R is 4,4'-biphenylene, the primary toughening agent is a silicone-modified methyl methacrylate-butyl acrylate core-shell copolymer, and the secondary toughening agent is polybutylene succinate ester, the glass fiber is glass fiber treated with tetraoctyloxytitanium bis[bis(tridecyl phosphite)] surface, the melting point of the thermotropic liquid crystal polymer is 260°C, the antioxidant Composed of hindered phenolic antioxidants and phosphite antioxidants with a mass ratio of 3:3, the hindered ...

Embodiment 3

[0036] The present embodiment provides a high-toughness flame-retardant nylon material, comprising the following components by weight: 60 parts of nylon resin, 40 parts of glass fiber, 20 parts of DOPO-based nitrogen-phosphorus flame retardant, 10 parts of main toughening agent, 2 parts Part of auxiliary toughening agent, 0.8 part of thermotropic liquid crystal polymer, 0.7 part of antioxidant; the structural formula of the DOPO-based nitrogen-phosphorus flame retardant is as follows: R is 1,4'-phenylene, the nylon resin is nylon 66 and nylon 6 with a mass ratio of 1:1, and the main toughening agent is methyl methacrylate-butadiene-styrene core-shell copolymer The auxiliary toughening agent is polyε-caprolactone, and the glass fiber is glass fiber treated with isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate, so The melting point of the thermotropic liquid crystal polymer is 280°C, and the antioxidant is composed of a hindered phenolic antioxidant and a phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com