Heat-insulating coating material for medical catheters and preparation method and application of heat-insulating coating material

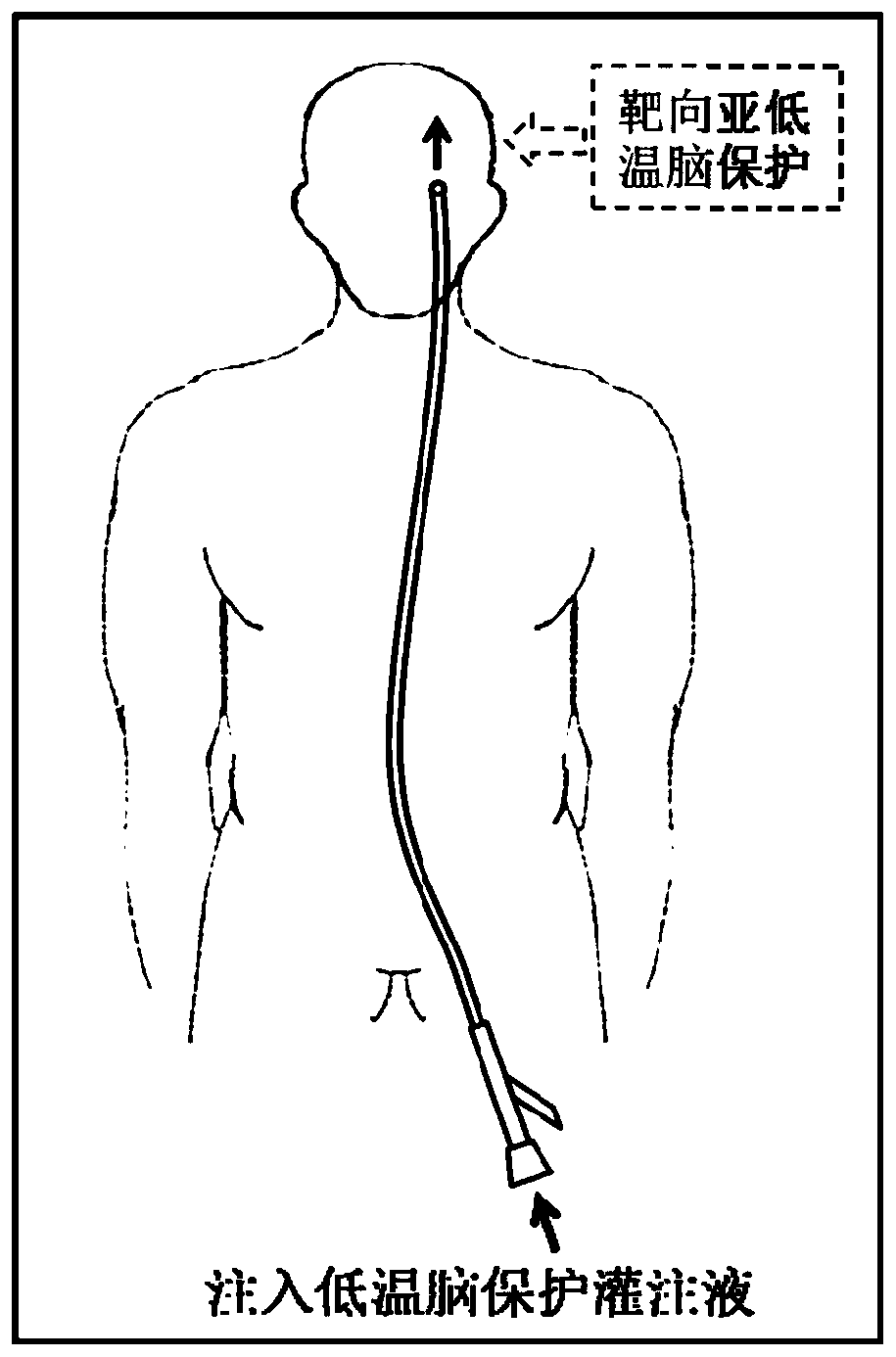

A technology of thermal insulation coating and medical catheter, applied in catheter, coating, protein coating and other directions, can solve the problems of catheter without considering thermal insulation design, blood vessel rupture, low temperature performance reduction, etc. The effect of reducing autologous blood temperature drop, improving effectiveness and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

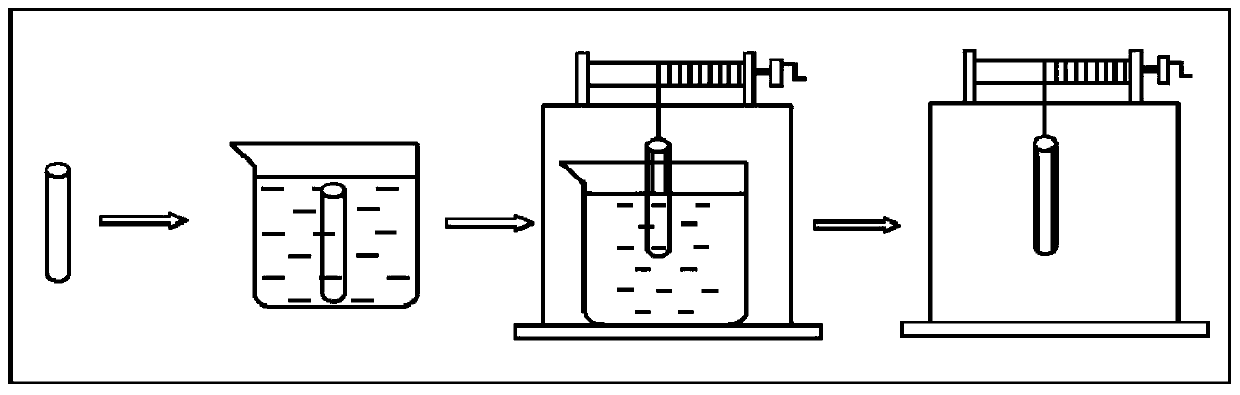

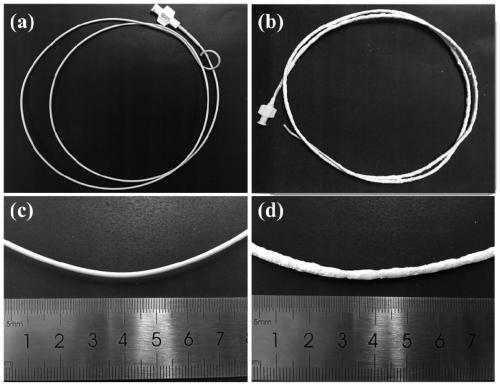

[0060] 1. Pretreatment of medical catheters and attachment of polydopamine film

[0061] Soak the medical catheter in anhydrous ethanol for 20min and sonicate it, take it out and air dry at room temperature.

[0062] A 0.01 mol / L Tris-HCl buffer solution with a pH of 8.5 was prepared, and dopamine was added to the solution to make the concentration 2 mg / mL to obtain an alkaline medium containing dopamine.

[0063] Soak the medical catheter in the dopamine-containing alkaline medium, and react in the dark for 12 hours under the condition of magnetic stirring at 500 rpm, and the dopamine can undergo oxidative polymerization reaction, and a polydopamine film layer strongly attached to the surface of the catheter can be obtained. After detection, the polydopamine film layer is about 500 nm.

[0064] 2. Preparation of thermal insulation coating material (sol)

[0065] Under the condition of magnetic stirring at 500 rev / min, silicon dioxide nanometer hollow spheres are added into ...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is only that: when preparing the thermal insulation coating material (sol), the quality of the silicon dioxide nano hollow spheres added is 10% of the mass of the silk fibroin aqueous solution.

Embodiment 3

[0072] The difference between this embodiment and embodiment 1 is only that: when preparing the thermal insulation coating material (sol), the quality of the silicon dioxide nano hollow spheres added is 30% of the mass of the silk fibroin aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com