Antibacterial and hypoallergenic adult paper diapers and preparation method thereof

An anti-allergic, paper diaper technology, applied in the field of sanitary products, can solve the problems of moisture permeability, poor water permeability, easy breeding of bacteria, easy side leakage, etc., to achieve the effect of easy putting on and taking off, promoting the use and eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a preparation method of antibacterial and hypoallergenic adult paper diapers, the specific steps are as follows:

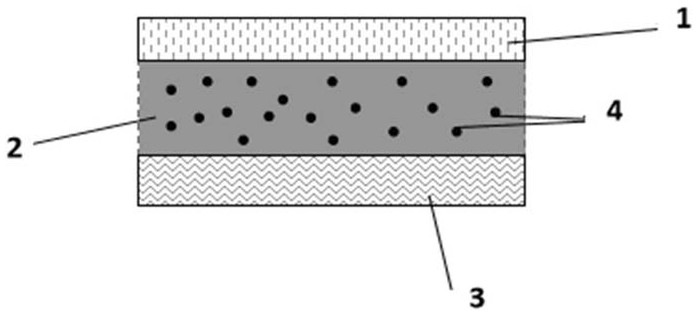

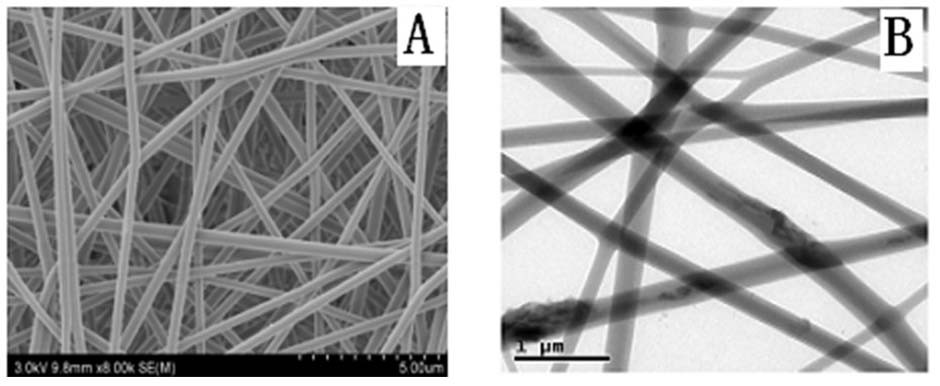

[0033] Step 1, preparation of skin-friendly layer

[0034] (1) Preparation of drug-loaded halloysite: 50 mL of chlorhexidine gluconate saturated solution (40 mg / mL) was prepared with absolute ethanol as a solvent, and 0.5 g of dried halloysite powder was dispersed in the drug solution. The obtained suspension is vacuum-suctioned. The specific method is that the suspension is placed in a vacuum environment by a vacuum pump, the air in the halloysite tube cavity is removed, and the vacuum is removed after 30 minutes of vacuum pumping to restore the normal pressure state in the container. Air enters the container; the above steps are repeated twice to ensure that the drug can enter the nanotube lumen to the maximum to achieve the maximum loading rate. After completing the vacuum suction work, the halloysite and drug suspension was cen...

Embodiment 2

[0056] Step 1, preparation of skin-friendly layer

[0057] (1) Preparation of drug-loaded halloysite: 50 mL of chlorhexidine gluconate saturated solution (40 mg / mL) was prepared with absolute ethanol as a solvent, and 0.5 g of dried halloysite powder was dispersed in the drug solution. The suspension is vacuumed under a vacuum pump to remove the air in the halloysite tube cavity. After 30 minutes of vacuuming, the vacuum is removed to restore the normal pressure in the container, and the air enters the container; the above steps are repeated twice to ensure that the drug can reach the maximum. Maximum loading rate is achieved with limited access to the nanotube lumen. After completing the vacuum suction work, the halloysite and drug suspension was centrifuged at 9000 rpm for 10 min, and the supernatant was removed. The collected precipitate was washed twice with deionized water to remove drug molecules not bound to halloysite. Finally, the halloysite precipitate is resuspend...

Embodiment 3

[0071] Step 1, preparation of skin-friendly layer

[0072] (1) Preparation of drug-loaded halloysite: 50 mL of chlorhexidine gluconate saturated solution (40 mg / mL) was prepared with absolute ethanol as a solvent, and 0.5 g of dried halloysite powder was dispersed in the drug solution. The suspension is vacuumed under a vacuum pump to remove the air in the halloysite tube cavity. After 30 minutes of vacuuming, the vacuum is removed to restore the normal pressure in the container, and the air enters the container; the above steps are repeated twice to ensure that the drug can reach the maximum. Maximum loading rate is achieved with limited access to the nanotube lumen. After completing the vacuum suction work, the halloysite and drug suspension was centrifuged at 9000 rpm for 10 min, and the supernatant was removed. The collected precipitate was washed twice with deionized water to remove drug molecules not bound to halloysite. Finally, the halloysite precipitate is resuspend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com