Nerve repair membrane and preparation method and applications thereof

A nerve repair and equipment technology, which is applied in textiles and papermaking, medical science, fiber processing, etc., can solve the problems of poor electrical conductivity of nerve repair cannula, poor electrical conductivity of composite nerve catheter, and poor nerve repair effect, and achieves the realization of Directed growth, excellent repair effect, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

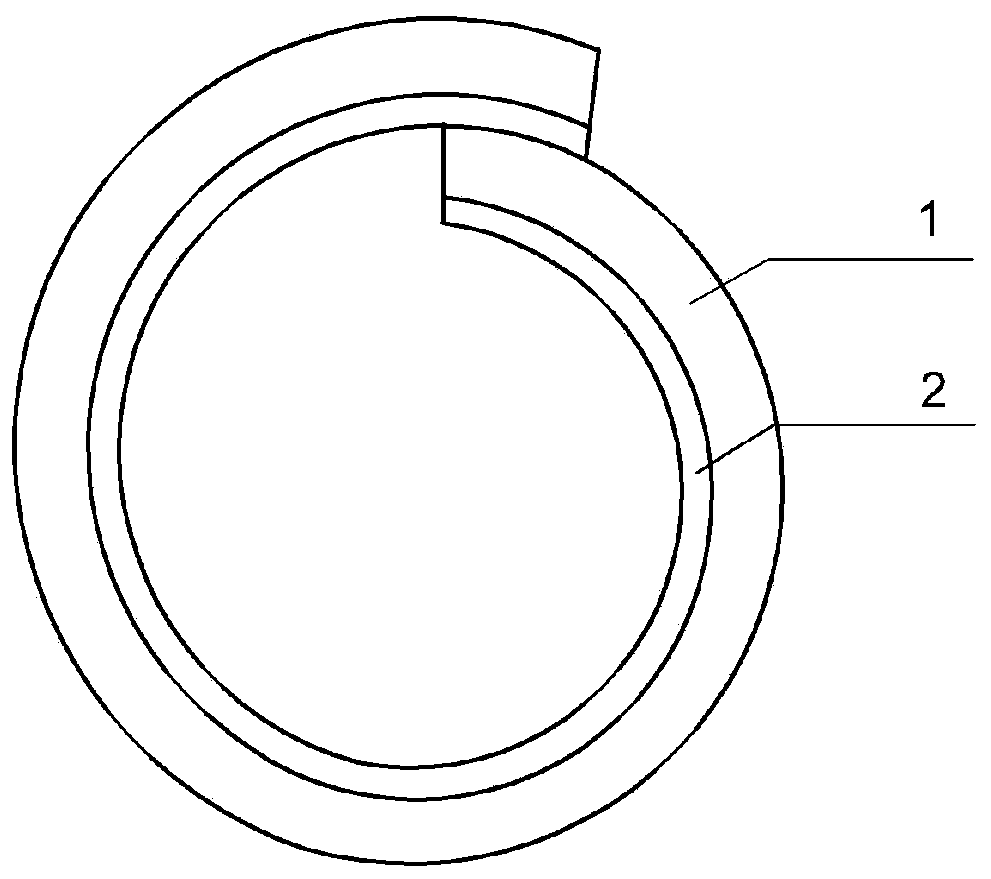

Image

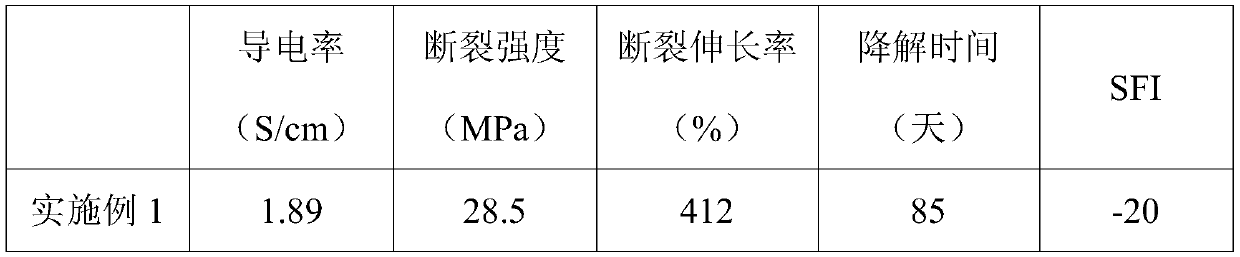

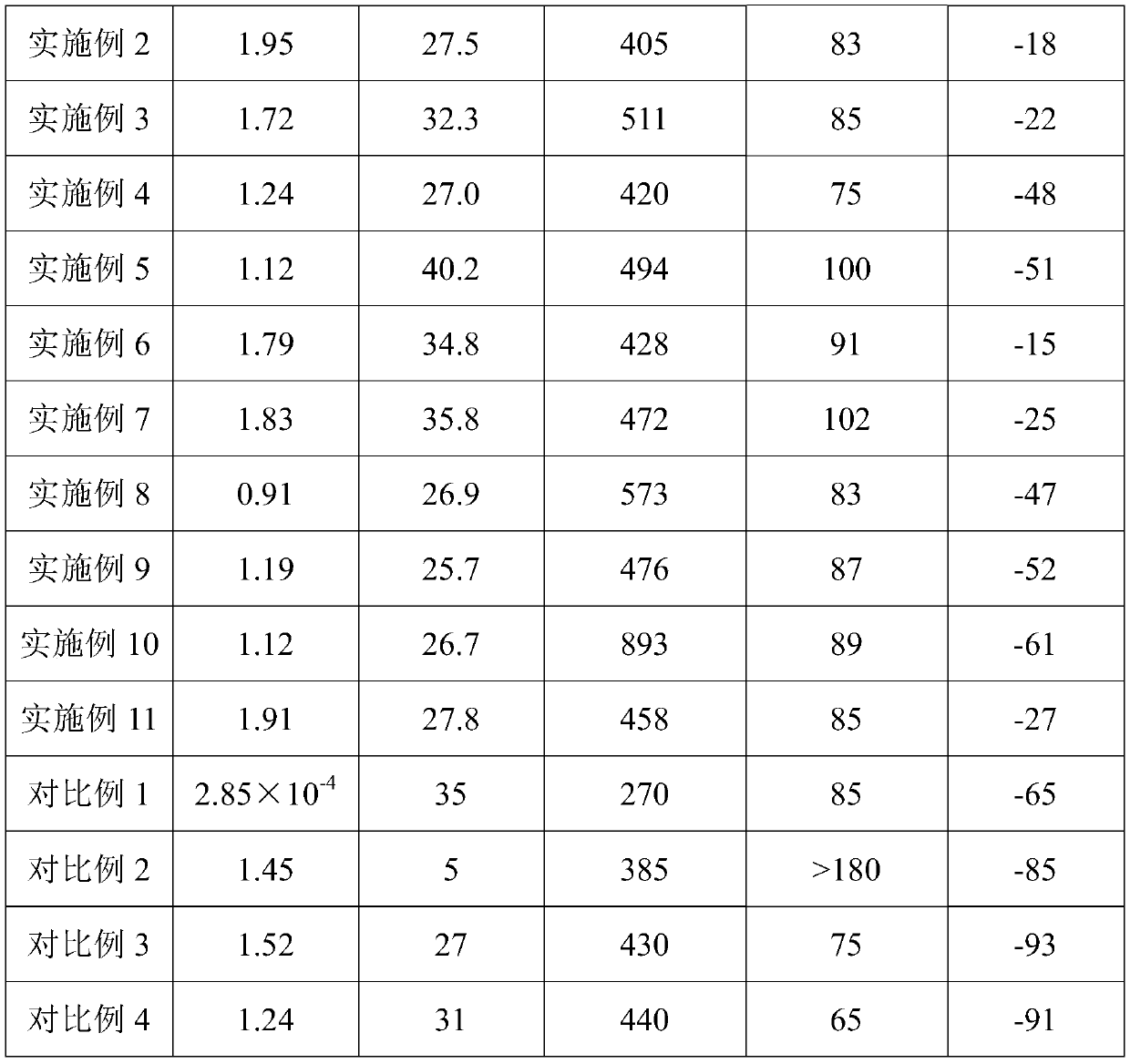

Examples

Embodiment 1

[0060] This embodiment provides a nerve repair membrane, which is prepared by the following method:

[0061] (1) Preparation of electrospinning stock solution:

[0062] The lactide-caprolactone copolymer (M w =270000) was dissolved in hexafluoroisopropanol to obtain an electrospinning stock solution whose mass fraction of lactide-caprolactone copolymer was 20%;

[0063] (2) Preparation of fiber membrane:

[0064] Inject the electrospinning stock solution into the syringe, inject the electrospinning stock solution at a speed of 2mL / h under the action of the propulsion pump of the electrospinning equipment, and perform electrospinning under a loading voltage of 15kV, and use a metal rotating receiving plate to receive the electrospinning stock solution. The lactide-caprolactone copolymer fiber film obtained by electrospinning, and the lactide-caprolactone copolymer fiber film was placed in a vacuum drying oven to dry for 40h, and the finally obtained lactide-caprolactone The ...

Embodiment 2

[0069] The difference from Example 1 is that the electrospinning stock solution with a mass fraction of lactide-caprolactone copolymer prepared in step (1) is 15%, and the lactide-caprolactone copolymer obtained in step (2) The diameter of the electrospun fibers in the biofibrous membrane is 0.5 μm.

Embodiment 3

[0071] The difference from Example 1 is that the electrospinning stock solution with a mass fraction of lactide-caprolactone copolymer prepared in step (1) is 30%, and the lactide-caprolactone copolymer obtained in step (2) The diameter of the electrospun fibers in the biofibrous membrane is 2.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com